Fluorinated polyurethane porous membrane

A polyurethane and porous membrane technology, applied in the direction of grinding workpiece supports, etc., can solve the problems of high surface activity, low water solubility, long hydrophobic chains, etc., and achieve the effect of slowing down rapid penetration, avoiding high water absorption, and excellent damping and anti-skid performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

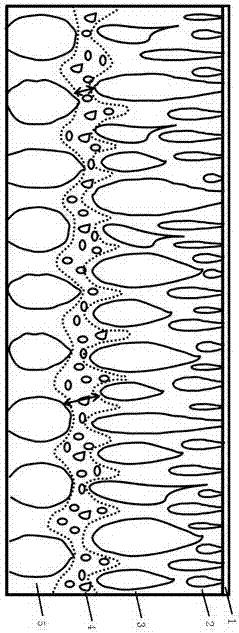

Image

Examples

Embodiment 1

[0049] Prepared by dissolving 8.000g of fluorine-containing polyester polyurethane (hardness 95A) and 68.775g polyether polyurethane (hardness 85A) with a fluorine content of 1% in 307.100g N,N-dimethylformamide (DMF) at room temperature into a polyurethane solution with a concentration of 20%, then add 2.400g carbon black, 0.200g acryloyl diquaternary ammonium salt, then add 0.005g benzoyl peroxide, 0.500g hydrophilic surfactant, 0.120g Leveling agent, and supplemented with 612.9g DMF, then the solution of the composition was ground at 50°C for 1.2 hours, and the resulting solution was subjected to defoaming treatment to obtain a fluorine-containing polyurethane resin composition with a concentration of 8.00% and a viscosity of 500 centipoise .

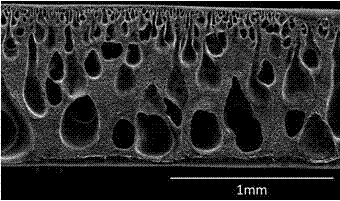

[0050] Coat the fluorine-containing polyurethane resin composition on the base material or mold, immerse in a coagulation bath containing 10% DMF and 90% water for coagulation and regeneration, wash and dry to obtain a fluorine-conta...

Embodiment 2

[0054] Dissolve 25.000g of fluorine-containing polyether polyurethane (hardness 85A) and 69.700g polycarbonate polyurethane (hardness 90A) with a fluorine content of 2% in 378.800g N,N-dimethylformamide (DMF) at room temperature Prepare a polyurethane solution with a concentration of 20%, then add 5.000g carbon black, 0.300g acryloyl diquaternary ammonium salt, then add 0.005g benzoyl peroxide, 0.500g hydrophilic surfactant, 0.150g leveling agent, and supplemented with 520.545g DMF, then the solution of the composition was ground at 50°C for 1.5 hours, and the resulting solution was subjected to defoaming treatment to obtain a fluorine-containing polyurethane resin composition with a concentration of 10.07% and a viscosity of 850 centigrade moor.

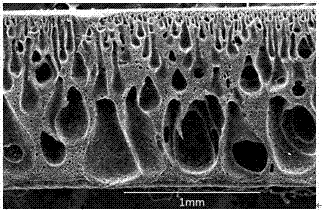

[0055] Coat the fluorine-containing polyurethane resin composition on the base material or mold, immerse in a coagulation bath containing 10% DMF and 90% water for coagulation and regeneration, wash and dry to obtain a fluorine-cont...

Embodiment 3

[0059] Dissolve 50.000g of fluorine-containing polycarbonate polyurethane (90A hardness) and 92.000g polyester polyurethane (95A hardness) with a fluorine content of 3% in 568.000g N,N-dimethylformamide (DMF) at room temperature Prepare a polyurethane solution with a concentration of 20%, then add 8.000g carbon black, 0.400g acryloyl diquaternary ammonium salt, add 0.006g benzoyl peroxide, 0.800g hydrophilic surfactant, 0.220g leveling agent, and supplemented with 280.574g DMF, then the solution of the composition was ground at 50°C for 1.5 hours, and the resulting solution was subjected to defoaming treatment to obtain a fluorine-containing polyurethane resin composition with a concentration of 15.10% and a viscosity of 1250 centimeters moor.

[0060] Coat the fluorine-containing polyurethane resin composition on the substrate or mold, immerse in a coagulation bath containing 10% DMF and 90% water for coagulation and regeneration, wash and dry to obtain a fluorine-containing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com