Pigment-type quick-drying neutral ink and ball point pen containing pigment-type quick-drying neutral ink

A neutral ink, ballpoint pen technology, applied in ballpoint pen, ink, printing and other directions, can solve the problems of inconvenient use of environmental protection, damage to writing experience, unsightly and other problems, to achieve the effect of promoting surface tension, avoiding writing hand feeling, and quick drying of stitches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

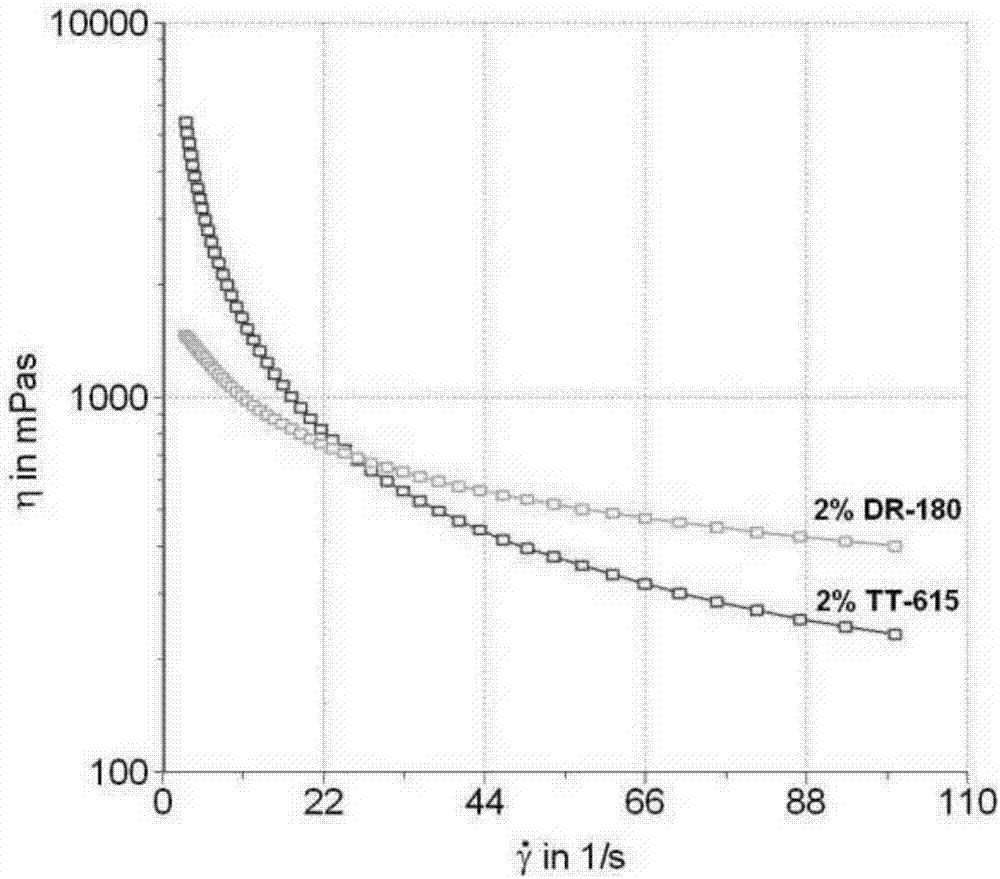

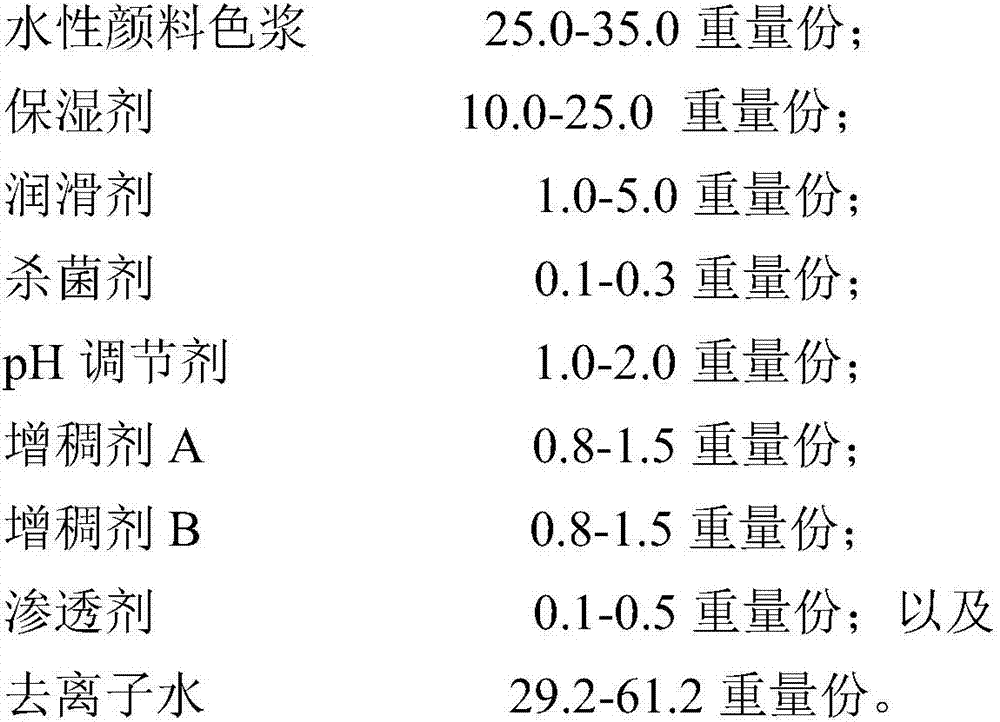

[0052] 39.2 parts of deionized water, 14 parts of polyethylene glycol PEG400, 6 parts of polyethylene glycol PEG300, 2 parts of fatty alcohol polyoxyethylene ether phosphate MOA-3P, 0.3 parts of polyether modified siloxane Twin 4200, 0.2 parts Add 1,2-benzisothiazolinone and 1.5 parts of triethanolamine into a stirring tank with paddle stirring, stir evenly at a low speed, add 0.8 parts of alkali swelling thickener TT-615 and 1.0 parts of Alkali-swellable thickener DR-180, as the molecular chain of the thickener gradually opens, the viscosity of the system increases, and the stirring speed is gradually increased. When the system is evenly mixed, continue to add 35 parts of carbon black with a mass concentration of 20% under stirring Water-based pigment paste until all materials are mixed evenly and the stirring is over.

[0053] The ink mixture prepared above was filtered through two stages of 1000 mesh and 1 micron to obtain a filtrate, which was then subjected to vacuum defo...

Embodiment 2

[0072] 39.2 parts of deionized water, 14 parts of polyethylene glycol PEG400, 6 parts of polyethylene glycol PEG300, 2 parts of fatty alcohol polyoxyethylene ether phosphate MOA-3P, 0.3 parts of polyether modified siloxane Twin 4200, 0.2 parts Add 1,2-benzisothiazolinone and 1.5 parts of triethanolamine into a stirring tank with paddle stirring, stir evenly at a low speed, add 1.0 parts of alkali swelling thickener HS 1152 and 1.0 parts of alkali under stirring Swelling thickener HS 1212, as the molecular chain of the thickener gradually opens, the viscosity of the system increases, and the stirring speed is gradually increased. When the system is evenly mixed, continue to add 35 parts of carbon black with a mass concentration of 20% water-based Pigment paste, until all materials are evenly mixed, the end of mixing.

[0073] The ink mixture prepared above was filtered through two stages of 1000 mesh and 1 micron to obtain a filtrate, which was then subjected to vacuum defoamin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface tension | aaaaa | aaaaa |

| thixotropic index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com