Aerobic fermentation tank

An aerobic fermentation and fermenter technology, which is applied in bioreactor/fermenter combinations, specific-purpose bioreactors/fermenters, biochemical instruments, etc. Oxygen rate and other issues to achieve the effect of reducing energy consumption and improving dissolved oxygen efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

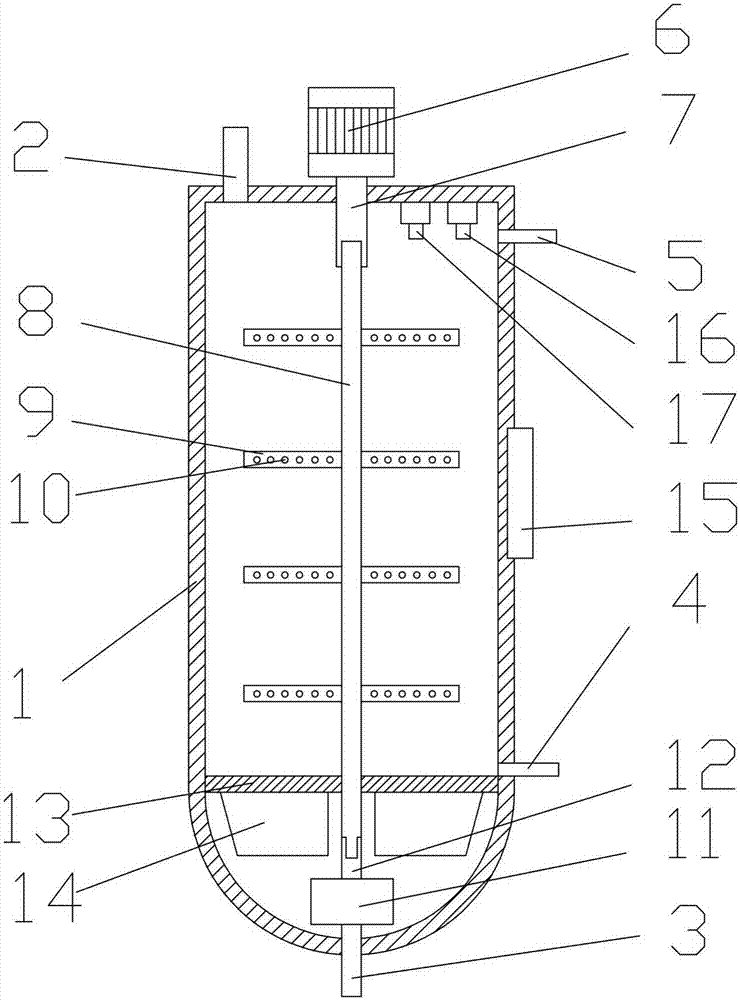

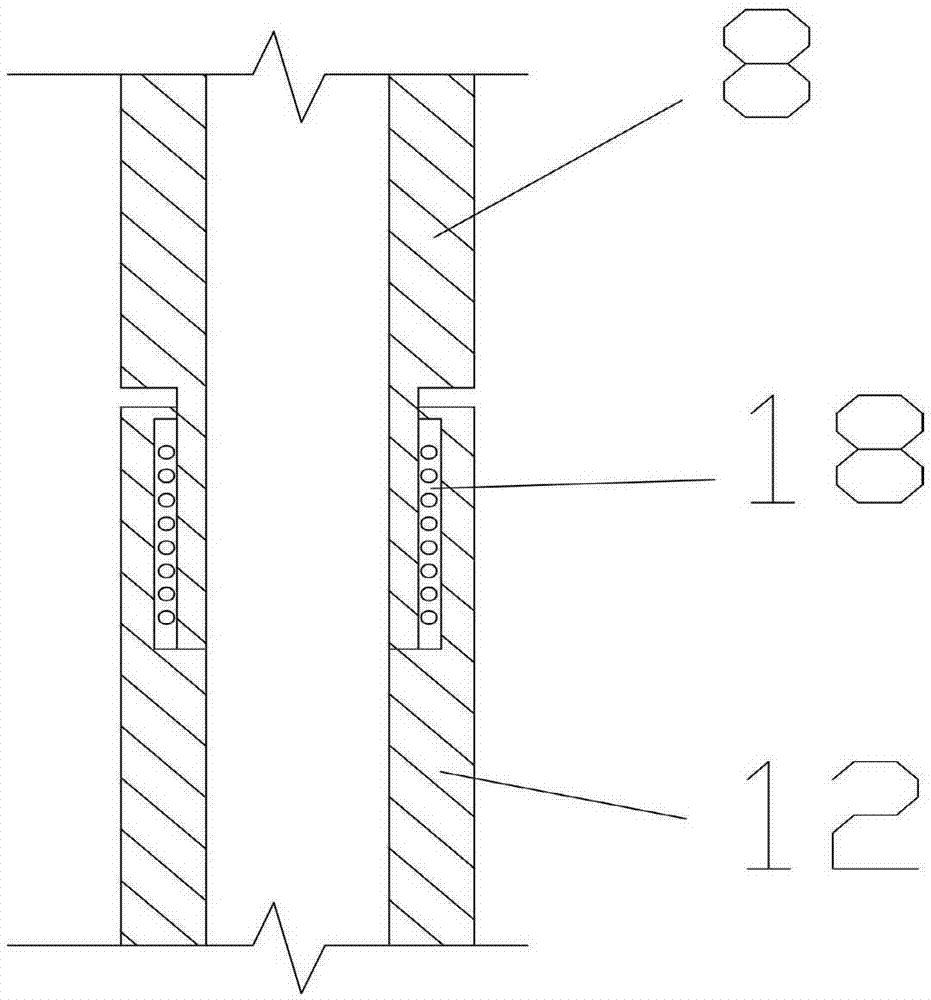

[0018] Combine below Figure 1-2 The present invention is further described:

[0019] An aerobic fermenter, which mainly includes a fermenter body 1, a feed port 2, an air inlet 3, a discharge port 4 and an exhaust port 5, the feed port 2 is arranged on the top right side of the fermenter body 1, The air inlet 3 is arranged in the middle of the bottom of the fermentation tank body 1, the discharge port 4 is arranged at the lower right side of the fermentation tank body 1, the exhaust port 5 is arranged at the right upper end of the fermentation tank body 1, and the top of the fermentation tank body 1 There is a motor 6 in the middle, the motor 6 is connected to the transmission rod 7, and the transmission rod 7 is connected to the rotatable air main pipe 8 arranged inside the fermentation tank 1, so as to achieve the purpose of the motor 6 driving the rotatable air main pipe 8 to rotate, and the rotatable air Several rotatable air branch pipes 9 are evenly distributed on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com