Assembly type phase-change heat insulation and photovoltaic power generation composite energy-saving wallboard and preparation method

A photovoltaic power generation panel and photovoltaic power generation technology, applied in photovoltaic power generation, photovoltaic modules, photovoltaic module support structures, etc., can solve problems such as low power generation efficiency of photovoltaic power generation panels, inability to install photovoltaic power generation panels in the installation area, and complicated installation processes, etc. Achieve the effect of satisfying the industrialized production of buildings, improving thermal comfort and high power generation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

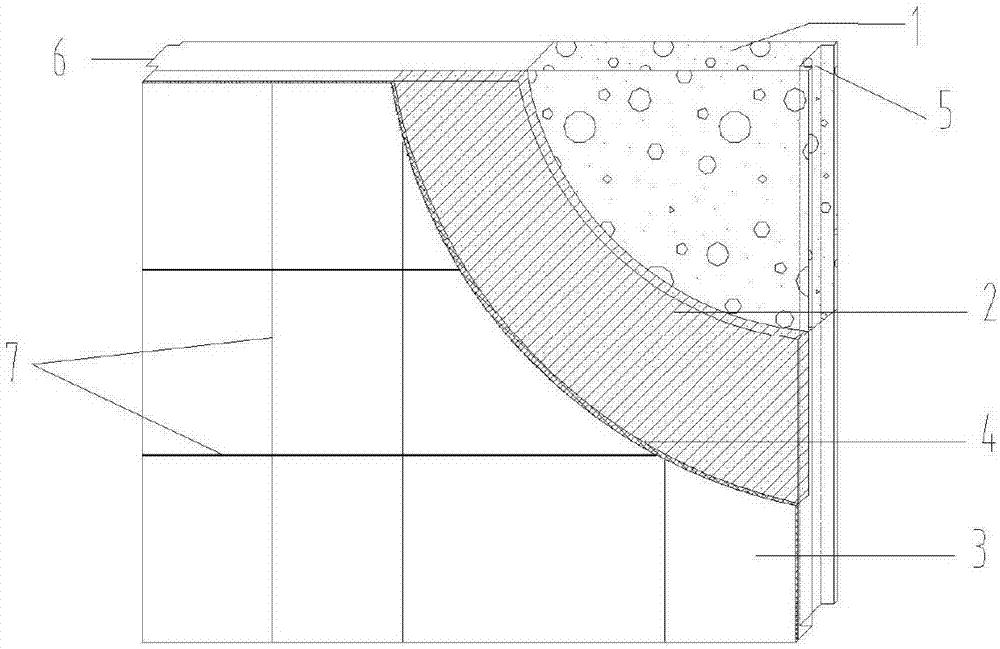

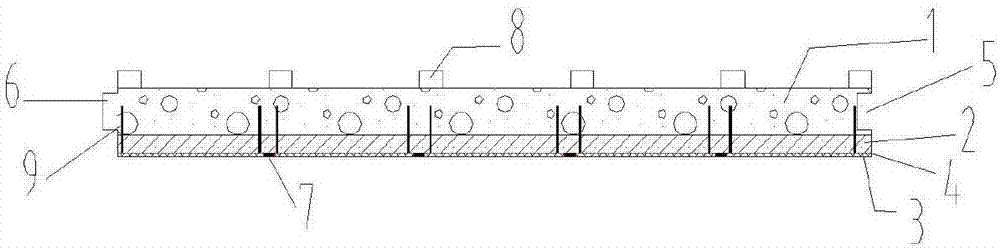

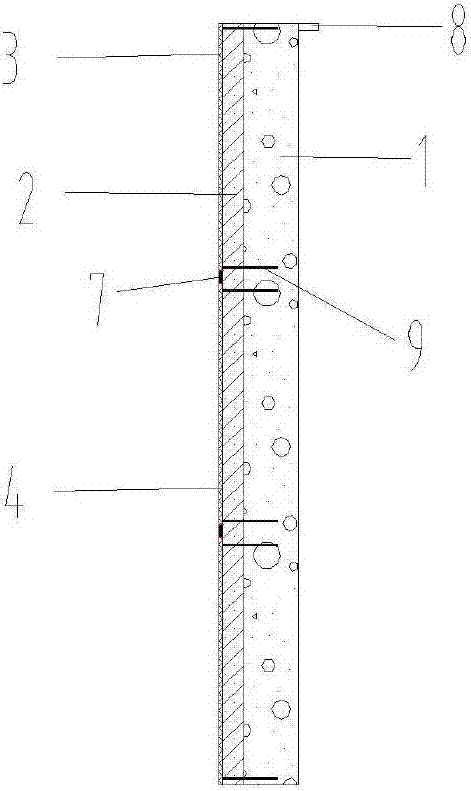

[0022] Such as Figure 1-3 As shown, an assembled phase-change thermal insulation-photovoltaic power generation composite energy-saving wall panel, which includes a composite body composed of a lightweight concrete wall panel 1, a phase-change thermal insulation layer 2 and a photovoltaic power generation panel 3, outside the concrete lightweight wall panel Paste or smear the phase change insulation layer 2, and hang the photovoltaic power generation panel 3 outside. There is an air layer between the phase-change thermal insulation layer 2 and the photovoltaic power generation panel 3, and the thickness of the air layer is 5mm-10mm. One side of the composite body is longitudinally provided with a wall panel groove 5, and the other side is provided with a wall panel tenon 6 matching with the wall panel groove 5, which can be quickly assembled at the construction site according to the actual situation.

[0023] The concrete lightweight wallboard 1 is made of foam concrete or ae...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com