Organic working medium absorption type power generation method and system driven by low-temperature heat source

A low-temperature heat source and power generation system technology, which is applied in the direction of machines/engines, mechanical equipment, steam engine devices, etc., can solve problems such as takeaway, large system equipment, and complex operation control, and achieve reduction of irreversible losses, high-tech economy, and high-speed operation control simple effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

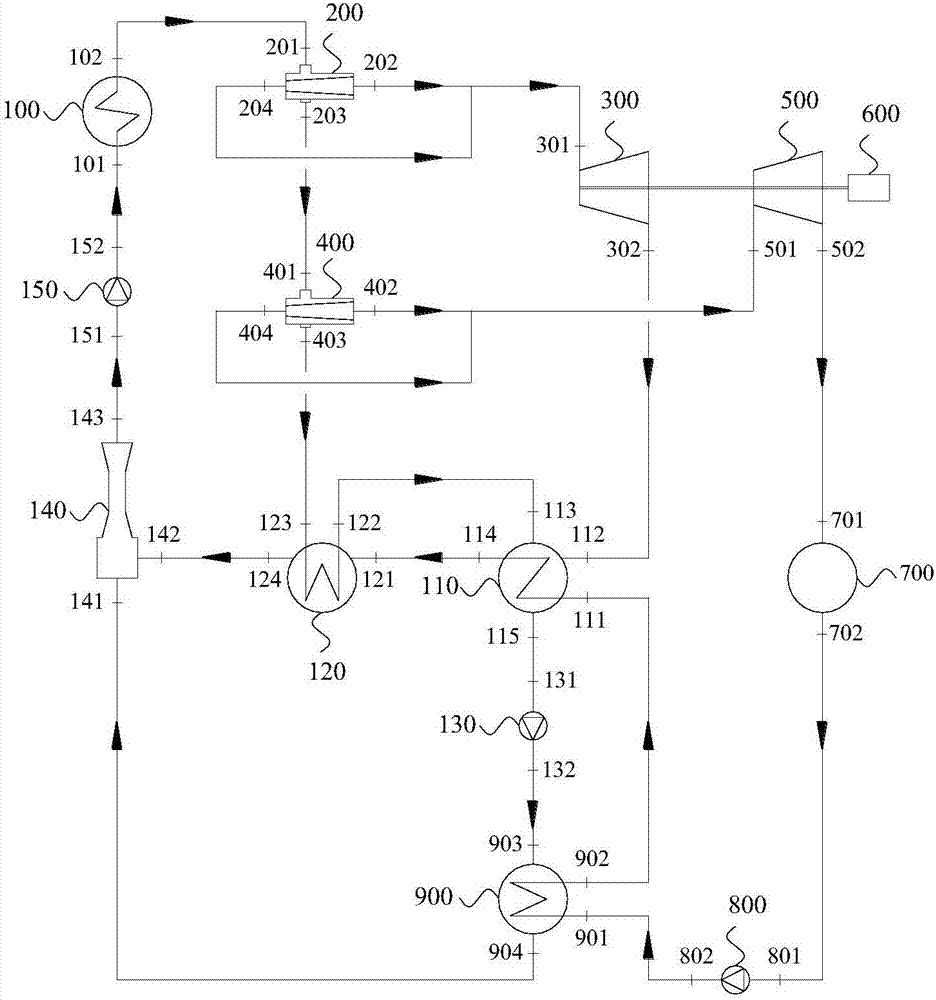

[0044] use as figure 1 The shown low-temperature heat source-driven organic working fluid absorption power generation system includes a heater 100 for heating the organic working fluid, a first vortex tube 200, a first expander 300, a second vortex tube 400, a second expander 500, Generator 600 , condenser 700 , refrigerant pump 800 , preheater 900 , absorber 110 , recuperator evaporator 120 , first solution pump 130 , jet adiabatic absorber 140 and second solution pump 150 . The saturated solution outlet 102 of the heater 100 is connected to the second inlet 201 of the first vortex tube 200, and the first hot gas outlet 202 of the first vortex tube 200 is connected in parallel with the first cold air outlet 204 to the third inlet of the first expander 300 301 connection, the first liquid outlet 203 of the first vortex tube 200 is connected with the fourth inlet 401 of the second vortex tube 400, the second hot gas outlet 402 of the second vortex tube 400 is connected in paral...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com