Hopper scale on-line automatic calibration method based on small number of weights

A technology of automatic calibration and hopper scales, which is applied in the direction of weighing equipment testing/calibration, etc., can solve the problems of uncertain accuracy of full scale or common points, physical injury of personnel carrying weights, and delay in time, so as to avoid personal injury , the results are intuitive and reliable, and the effect of using small effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

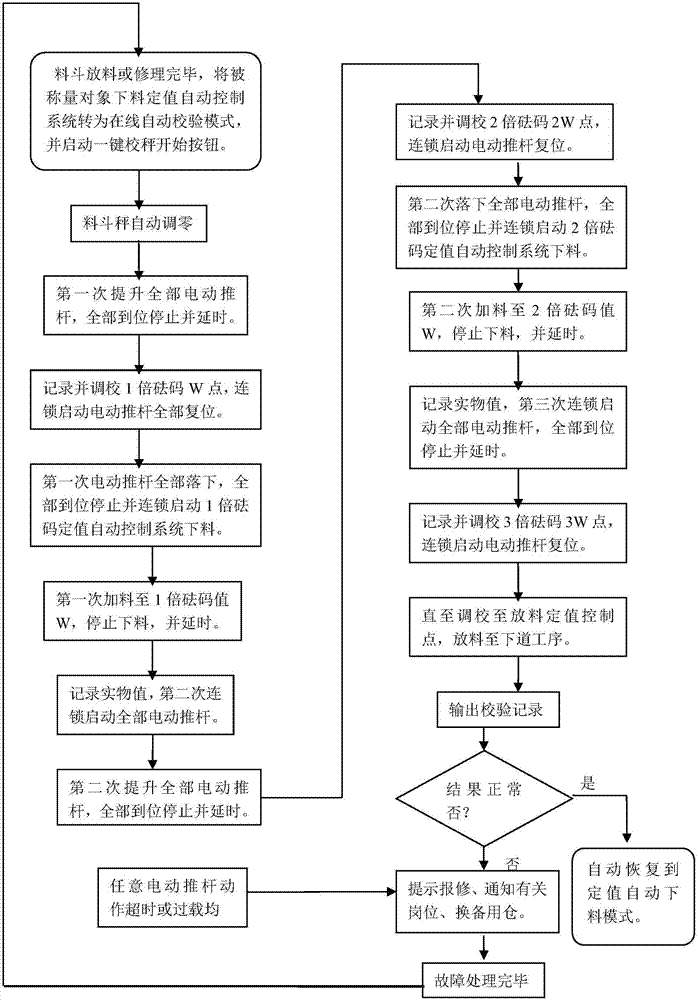

[0024] according to figure 1 , figure 2 An online automatic calibration method for a hopper based on a small amount of weights is shown, including the following steps:

[0025] Step 1: Test the repeatability with the actual object of 50% of the full scale and the smallest weight such as F which is 0.1 times of the division value e. The specific steps are as follows:

[0026] (1) Put the weighing object greater than 50% of the full scale into the hopper, the scale displays X, and add 0.1e small weights on the hopper one by one until X+e is displayed, at this time the cumulative value of the additional small weights is △ 1. Then release the weighing object and take down the △1 small weight, and return to zero;

[0027] (2) Put the object to be weighed into the hopper again, display X, add small weights of 0.1e on the hopper one by one, until X+e is displayed, at this time the cumulative value of the additional small weights is △2, and return to zero;

[0028] (3) Repeat the ...

Embodiment 2

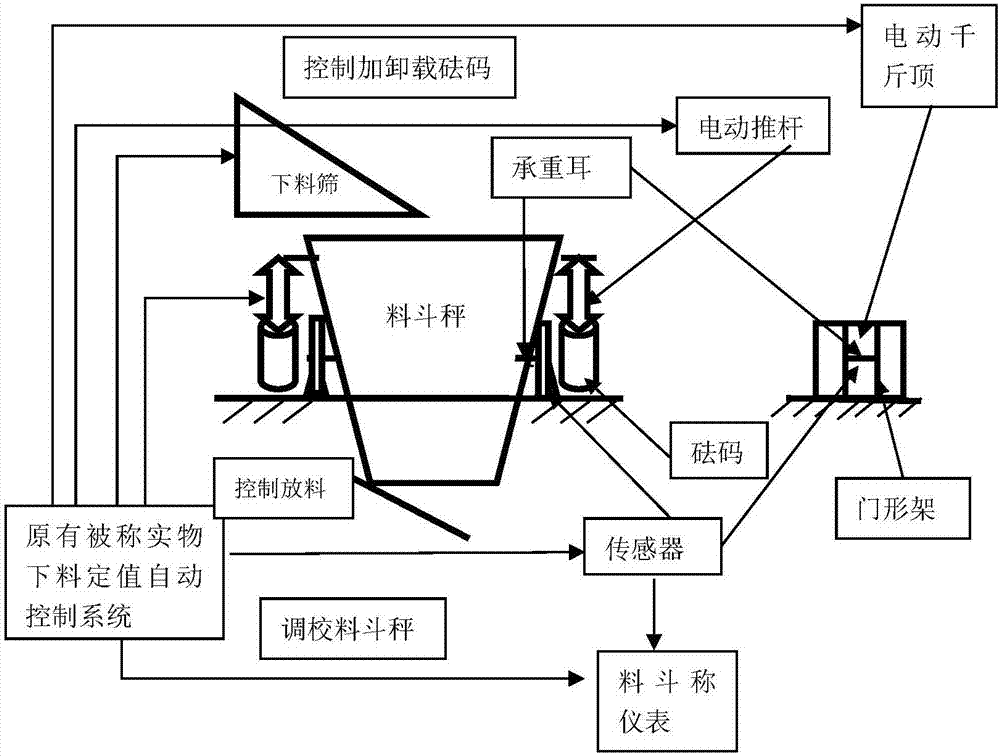

[0038] according to figure 2 An online automatic calibration method for hoppers based on a small amount of weights is shown. When the hopper scale does not have an automatic control system for feeding fixed value or when there is no time to feed, add a special remote control hopper scale force device, such as above the sensor A gantry is added above the load-bearing ears of the hopper, and a synchronous electric jack is added between the gantry beam and the load-bearing ears as a weight substitute. The two feet of the gantry and the sensor feet are fixed on a platform to achieve calibration Invention purposes other than using the synchronization function.

[0039] The on-line automatic calibration described in the present invention refers to the use of the hopper scale to be weighed or the electric jack as a weight substitute, and the calibration process is carried out simultaneously with the automatic control of the fixed value of normal feeding. A small amount of weight me...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com