A performance testing device and testing method for horizontal directional drilling through percussion drilling tools

A technology of horizontal directional drilling and testing equipment, which is applied in the direction of measuring equipment, testing of mechanical components, testing of machine/structural components, etc. It can solve the difficulty and cost of equipment maintenance due to the structure of the testing equipment, and increase the difficulty of sensor layout. Design of testing equipment Difficulty, inaccurate measurement of impact energy parameters, etc., to achieve the effect of improving accuracy and practicability, simple structure, and wide application range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

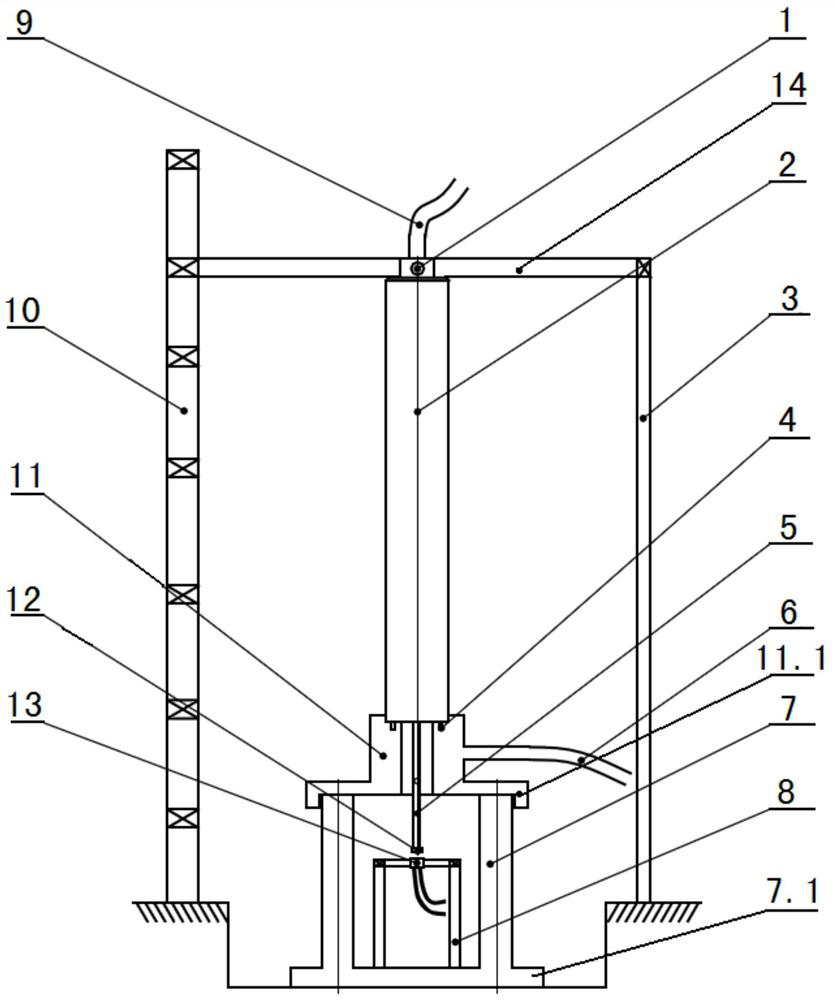

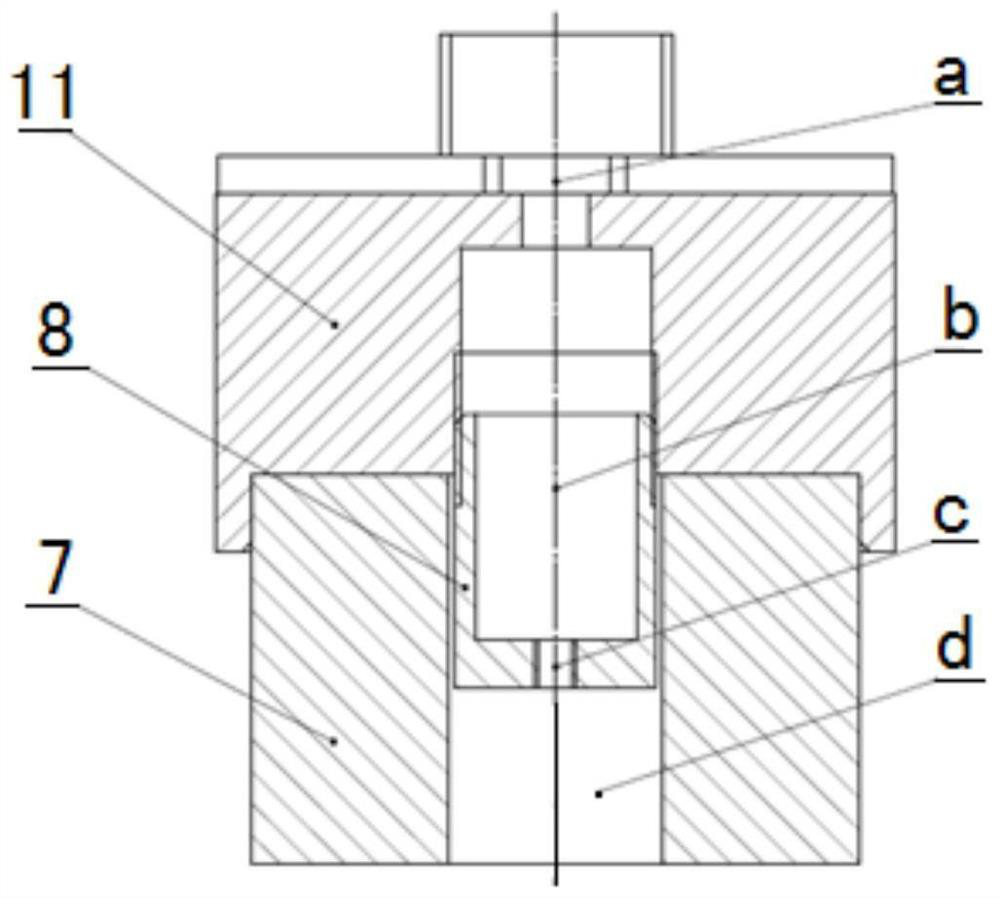

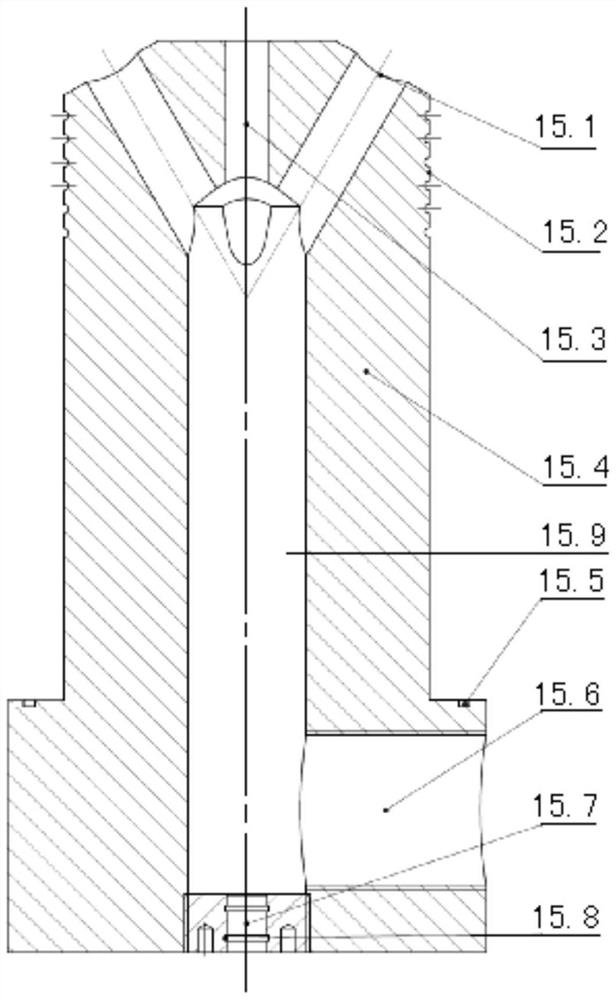

[0068] see figure 1 As shown, the embodiment of the present invention provides a performance testing device for horizontal directional drilling through percussion drilling tools, which is used to test the impact energy performance, impact force performance and impact frequency performance parameters of horizontal directional drilling through percussion drilling tools. The device at least includes: locking ring 1, impact drilling tool 2, hydraulic adjustment bracket 3, piezoelectric quartz sensor 4, moving connecting rod 5, drain pipe 6, support 7, sensor fastening sleeve 8, liquid inlet pipe 9 , fixed bracket 10, tray 11, induction steel plate 12, eddy current displacement sensor 13, beam 14, test anvil 15 and other components and data acquisition system and computer.

[0069] Specifically, the support 7 is a hollow cylinder with a circular chassis 7.1 extending from the bottom and placed semi-underground; the bottom of the tray 11 has a buckle edge 11.1, which is buckled on t...

Embodiment 2

[0074] see Figure 5 As shown, the embodiment of the present invention provides a method for testing the performance of a horizontal directional drilling percussion drilling tool, which is a non-contact measurement method, and tests the percussion drilling tool with the eddy current displacement sensor 13 in the performance testing device for horizontal directional drilling. 2 The impact velocity of the internal hammer at the end of the movement stroke realizes the impact energy test, impact force test and impact frequency parameter test of the horizontal directional drill through the percussion drilling tool 2. Taking the horizontal directional drilling drilling tool with an outer diameter of 203.2 mm and a working flow rate of 1500 L / s as an example, the test method at least includes: 1) test bench construction, 2) sensor installation, 3) impact drill Tool fixing, 4) high and low pressure manifold line connection, 5) power medium and equipment connection, 6) testing system d...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com