A method and control device for adaptive humidity generation based on shunt method

A technology of humidity generation and control device, applied in mixing methods, chemical instruments and methods, transportation and packaging, etc., can solve the problem of high dew point temperature, and achieve the effects of wide humidity range, low cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0018] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

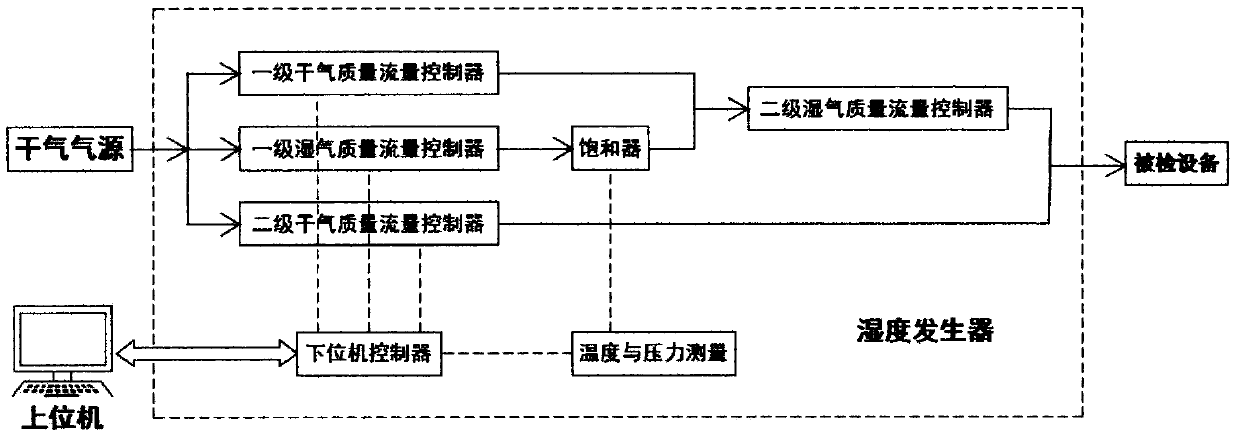

[0019] Such as figure 1 Shown is the composition block diagram of this humidity generation control device. The device is mainly composed of a humidity generator and a computer upper computer. The main components of the humidity generator are: primary dry gas mass flow controller, primary wet gas mass flow controller, secondary dry gas mass flow controller, secondary wet gas mass flow controller, saturator, temperature and Pressure sensor, lower computer controller. The computer upper computer is used for real-time communication with the humidity generator, controls the humidity generator to automatically generate the gas with the set dew point temperature, and monitors the actual output flow rate and saturator temperature of the humidity generator's four-way mass flow controller.

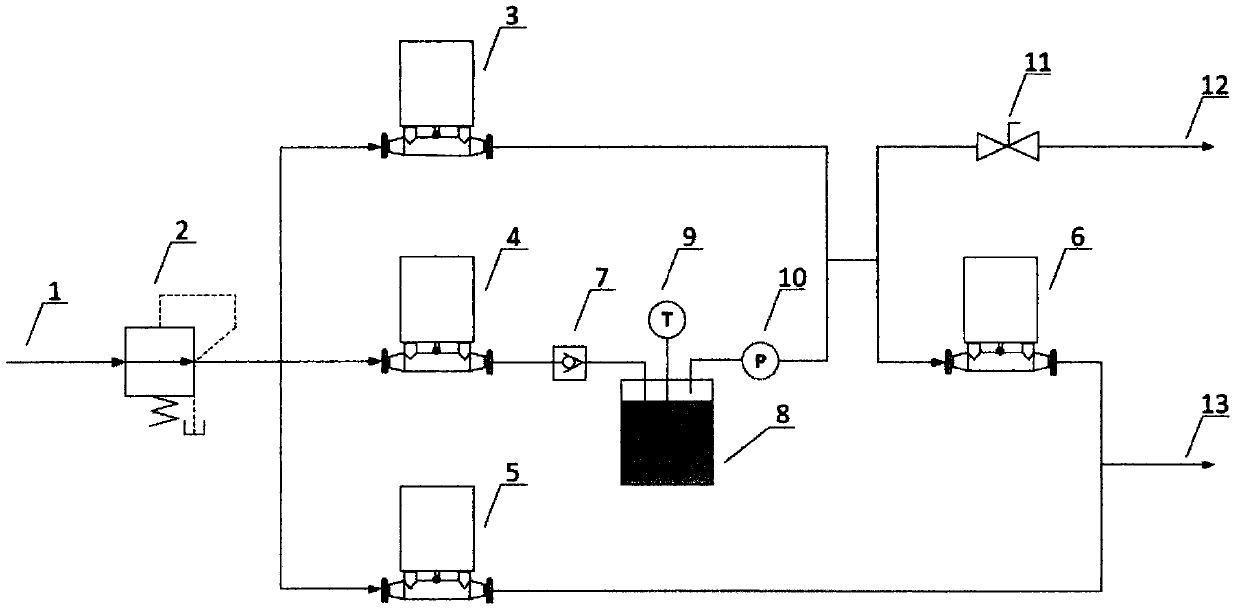

[0020] Such as figure 2 Shown is the schematic of the hu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com