Emulsion fuel manufacturing equipment

A technology for manufacturing equipment and fuel, applied in the field of emulsion fuel manufacturing equipment, can solve the problems of increasing the size of emulsion fuel manufacturing equipment, long time for manufacturing emulsion fuel, and increasing stages.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0073] Hereinafter, the preferred embodiments of the present invention will be described with reference to the accompanying drawings.

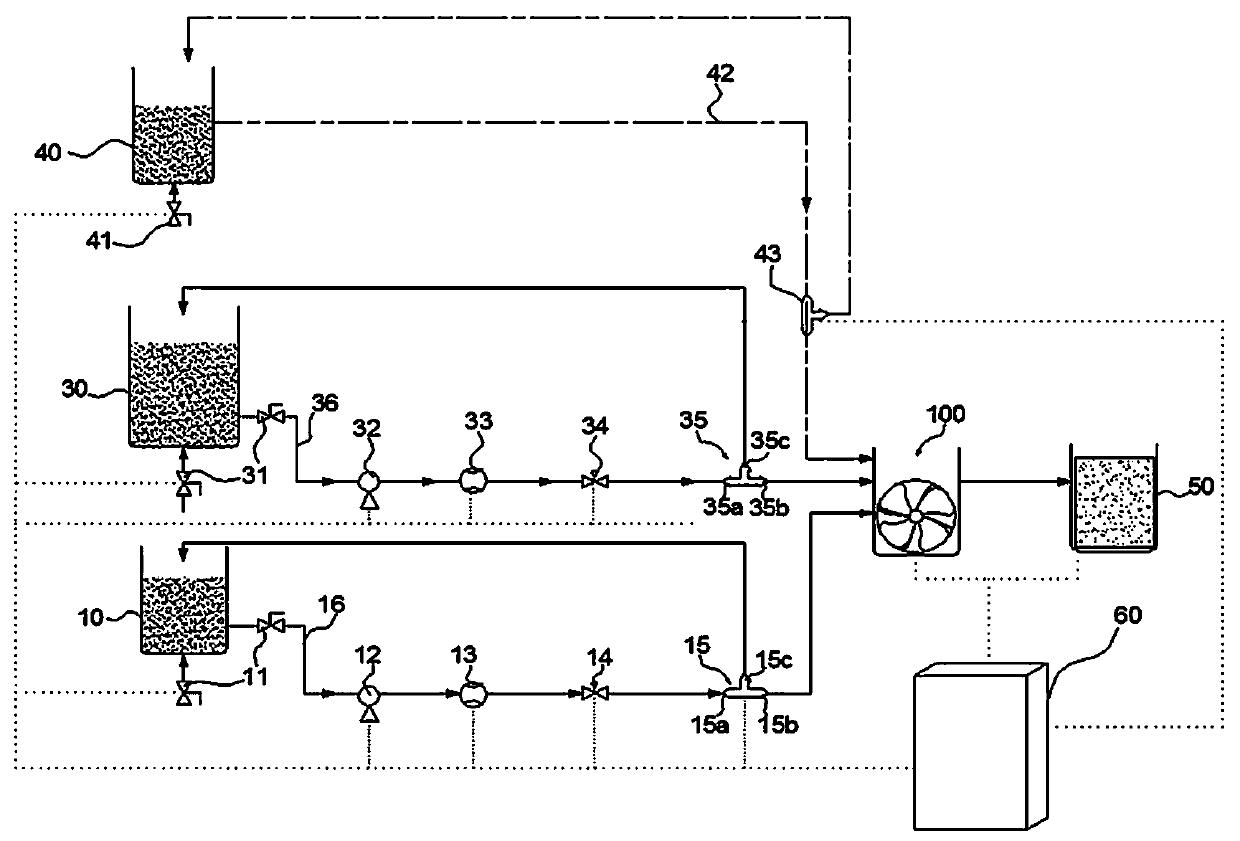

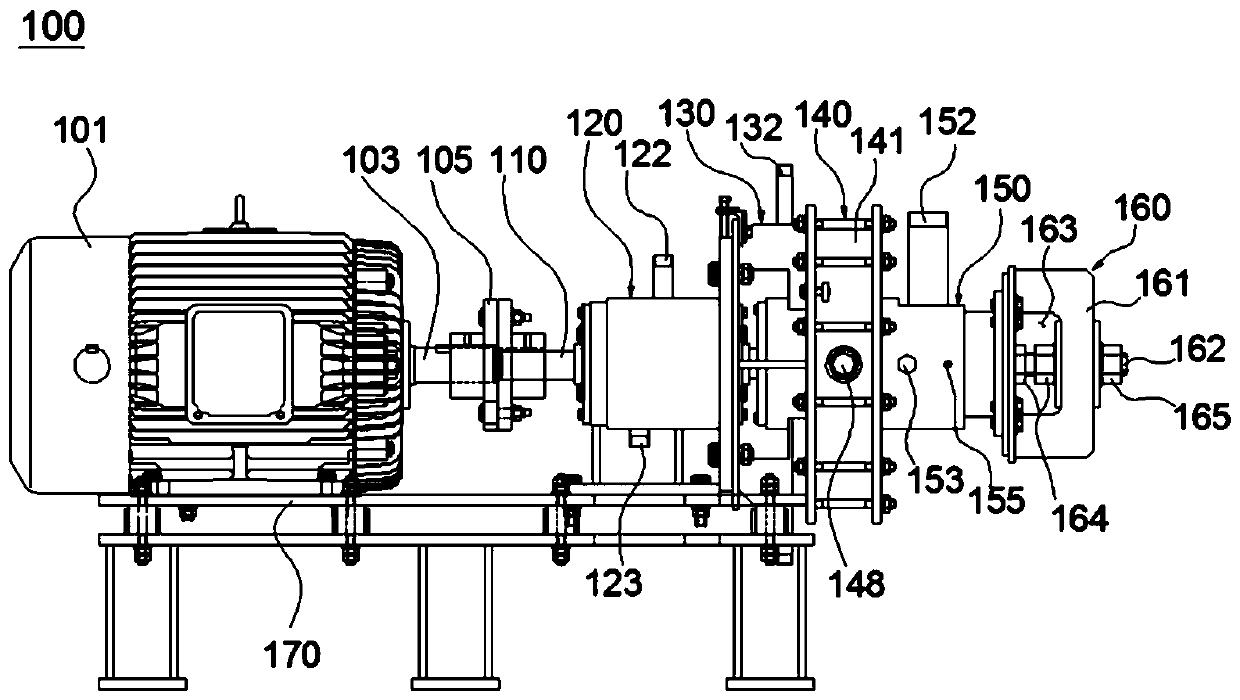

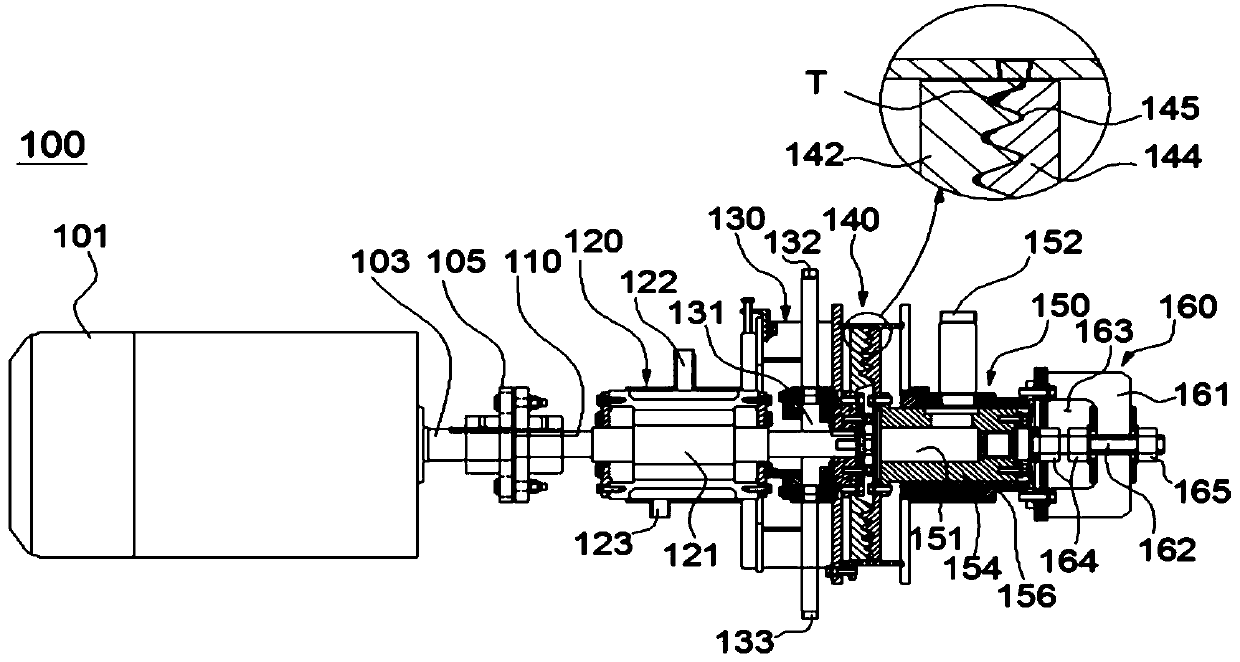

[0074] figure 1 is the overall structural block diagram of the emulsion fuel manufacturing equipment according to the present invention, figure 2 is a front view of an emulsion fuel manufacturing facility according to the present invention; image 3 Yes figure 2 A cross-sectional view of the illustrated emulsion fuel manufacturing facility.

[0075] and, Figure 4 to Figure 6 The process of introducing the emulsion raw material into the agitator and the flow state of the fluid discharged after emulsification of the input raw material are illustrated by the cross-sectional views of the raw material introduction part (150) and the emulsification part (140).

[0076] like figure 1 As shown, using the agitator (100) of the emulsion fuel manufacturing equipment according to the embodiment of the present invention, in order to manufacture the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com