Novel lathe tailstock

A lathe and tailstock technology, applied in the direction of tailstock/top, turning equipment, drilling/drilling equipment, etc., can solve the problems of reducing production efficiency, affecting production efficiency, consuming workers' time and physical strength, etc., to strengthen clamping effect, prolong service life, increase work efficiency effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Preferred embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings.

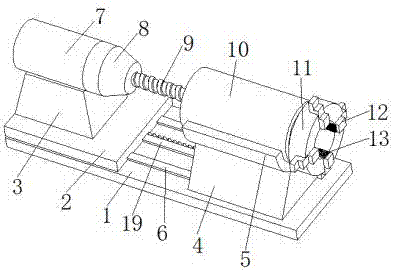

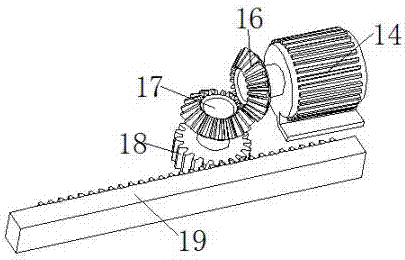

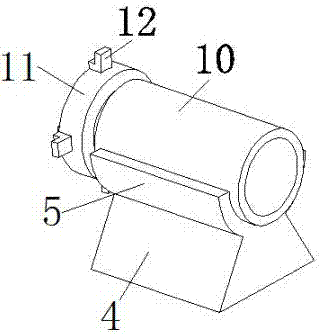

[0018] Figure 1 to Figure 6 Show the specific embodiment of the present invention: a new type of lathe tailstock, including a base plate 1, a first base 3, a second base 4, a four-jaw hydraulic chuck 11 and a gear 18, the base plate 1 is provided with two symmetrical Guide rail 6, slide plate 2 is slidably connected on guide rail 6, and described first base 3 is arranged on slide plate 2, and drill bit seat 7 is fixedly connected on the first base 3, and drill bit seat 7 is added at tail, can carry out workpiece like this While the peripheral surface is being processed, the tail of the workpiece is drilled. The drill bit holder 7 is threadedly connected with a drill bit 9. One side of the drill bit holder 7 is provided with an end cover 8. The inside of the first base 3 is provided with a single-phase motor 14. The single-phase The motor 14...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com