A method for forming a silkworm frame for cocoon cultivation of silkworms and a forming mold thereof

A technology for forming molds and forming methods, which is applied to household appliances, other household appliances, household components, etc., can solve problems such as unfavorable large-scale assembly line production, unfavorable growth of ants and silkworms, and low economic benefits, and achieves improved practicability and flexibility. , the rotation angle is uniform, and the effect of improving processing efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

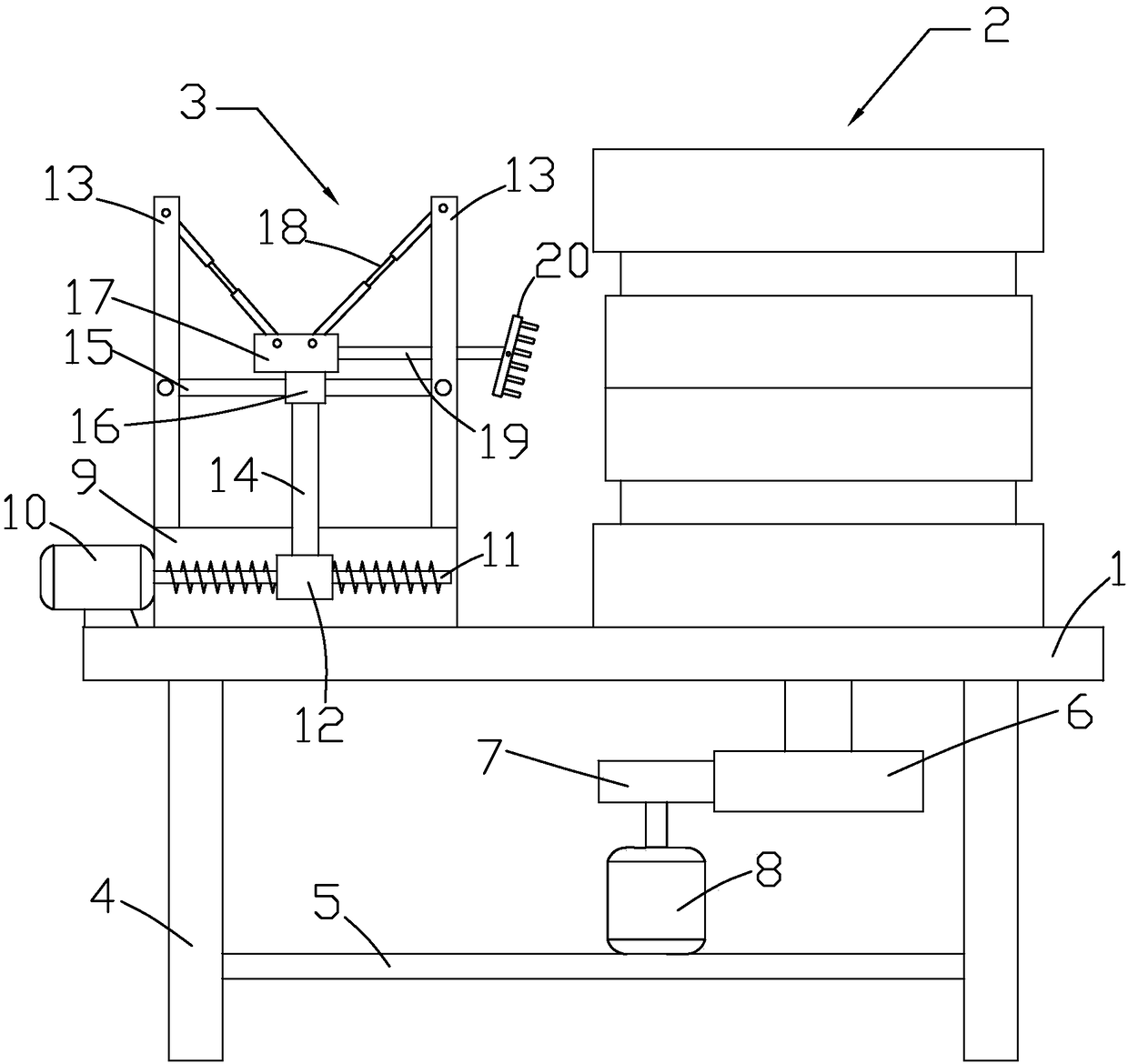

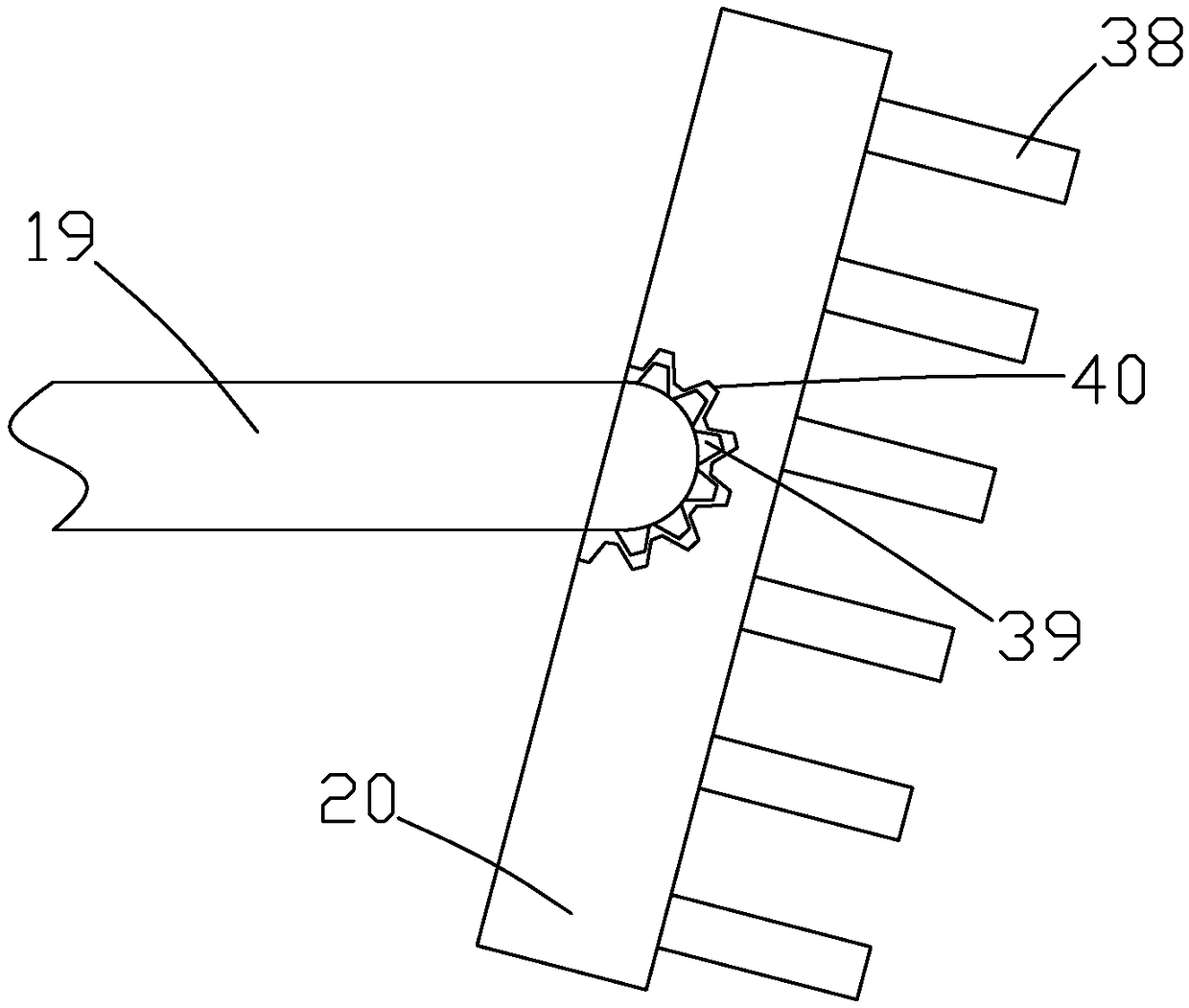

[0042] Such as Figures 1 to 4Shown, a kind of forming method of silkworm frame for silkworm camp cocoon, comprises the following steps:

[0043] (1) Forming mold installation and positioning

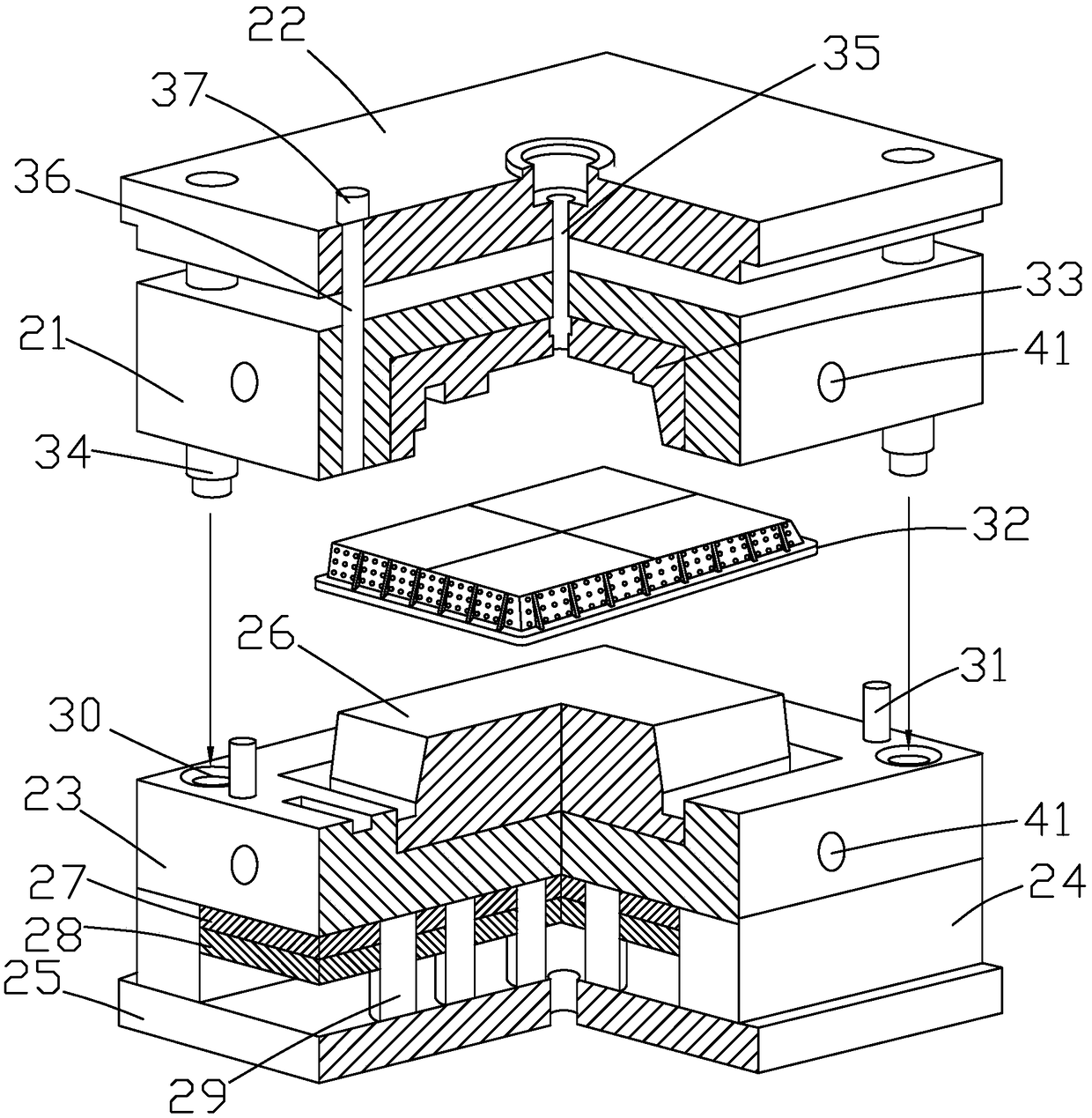

[0044] a. First, the female mold core 33 and the male mold core 26 will be designed according to the size of the silkworm frame, and the surface of the female mold core 33 and the male mold core 26 will be cut and smoothed by a cutting machine except for the extruded side, and then used The sandpaper is polished evenly, and then the female mold core 33 and the male mold core 26 are respectively installed in the corresponding female template 21 and the male template 23 for fixing, and at the same time, the part of the female mold core 33 that exceeds the bottom surface of the female template 21 is cut off to make the female mold The bottom of kernel 33 is flush with the bottom of female template 21, and the length of male mold kernel 26 beyond male template 23 is measured with a ruler, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com