Plasma processing device and method of uniform etching substrate

A technology of plasma and processing equipment, which is applied in the field of semiconductor processing and ion distribution, and can solve the problems of etching consumption on the surface of the focus ring, reduction of the surface height of the focus ring, and uneven etching rates in the center area and edge area of the substrate. , to achieve the effect of ensuring the uniformity of etching, increasing the thickness and saving costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0038] The technical solution of the present invention will be described in detail below in conjunction with the accompanying drawings.

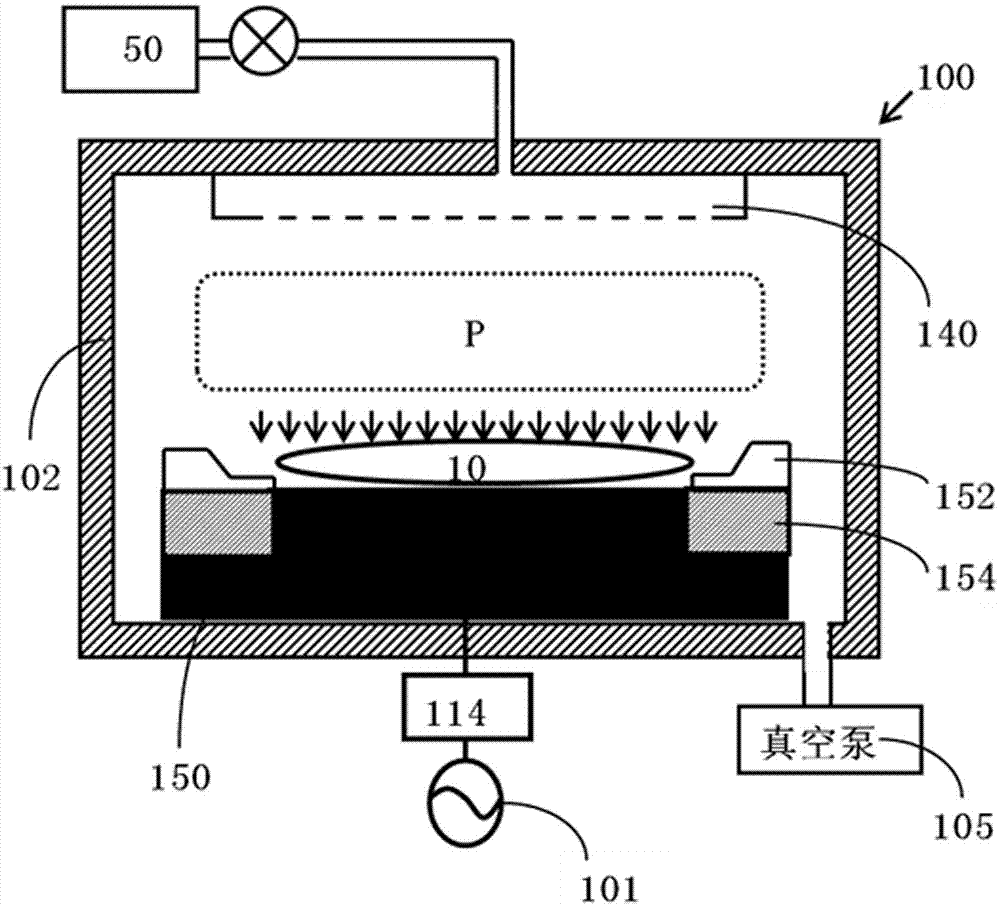

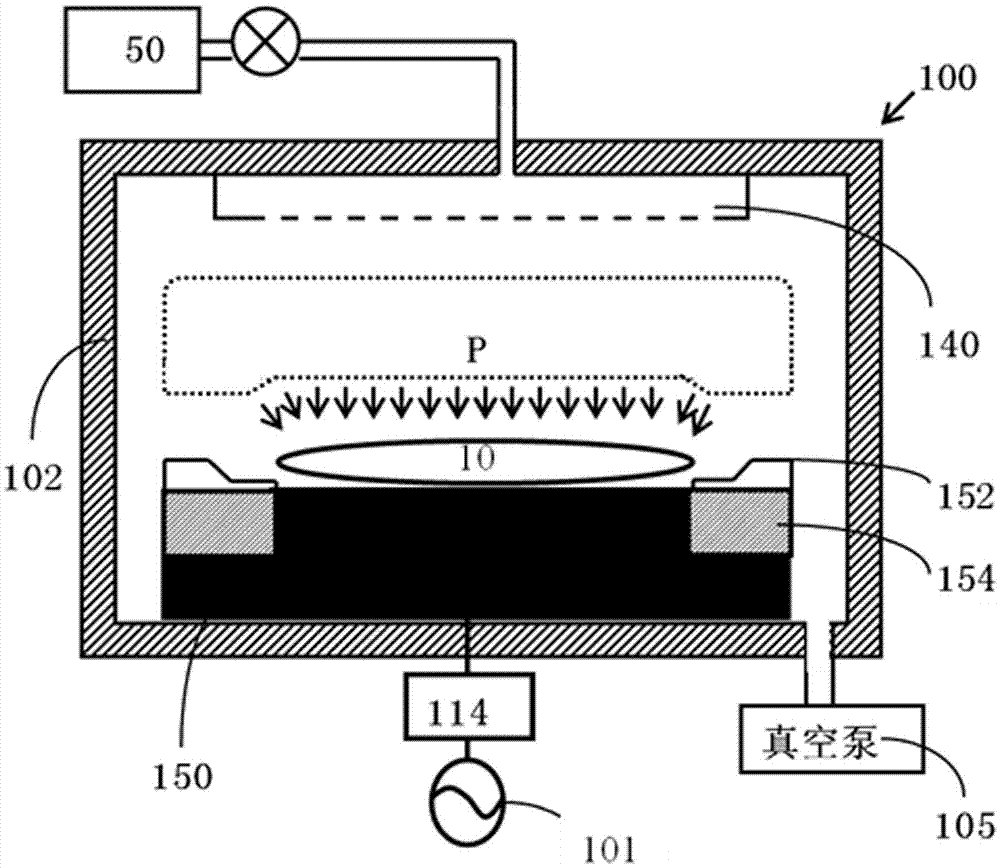

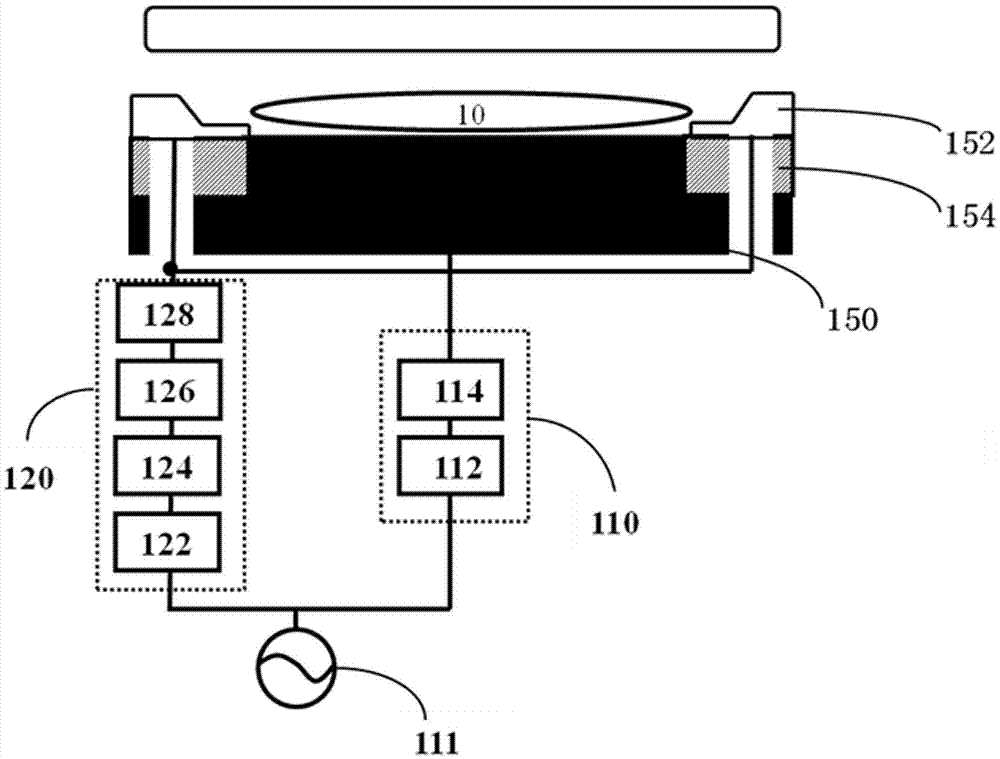

[0039] figure 1 A schematic structural view of a plasma processing device is shown. As shown in the figure, the plasma processing device includes a processing chamber 100, the processing chamber 100 is substantially cylindrical, and includes a vertical reaction chamber side wall 102, The processing chamber 100 has an upper electrode 140 and a lower electrode 150 arranged parallel to each other. The upper electrode 140 is connected with the reaction gas source 50, and the gas in the reaction gas source 50 is evenly injected into the inside of the reaction chamber through the upper electrode 140; A high radio frequency energy field is formed between them to form a processing area P that ignites and maintains the plasma, in which the reactive gas can be dissociated into the plasma required for the process. The lower electrode 150, also known ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com