Scaffold with copper carboxymethyl chitosan-sodium alginate and preparation method thereof and applications

A technology of carboxymethyl chitosan and sodium alginate, applied in medical science, tissue regeneration, prosthesis, etc., can solve problems such as uneven distribution of copper ions, immediate cross-linking of solutions, and limitations in practical applications, and achieve good antibacterial properties Effect, good biocompatibility, simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

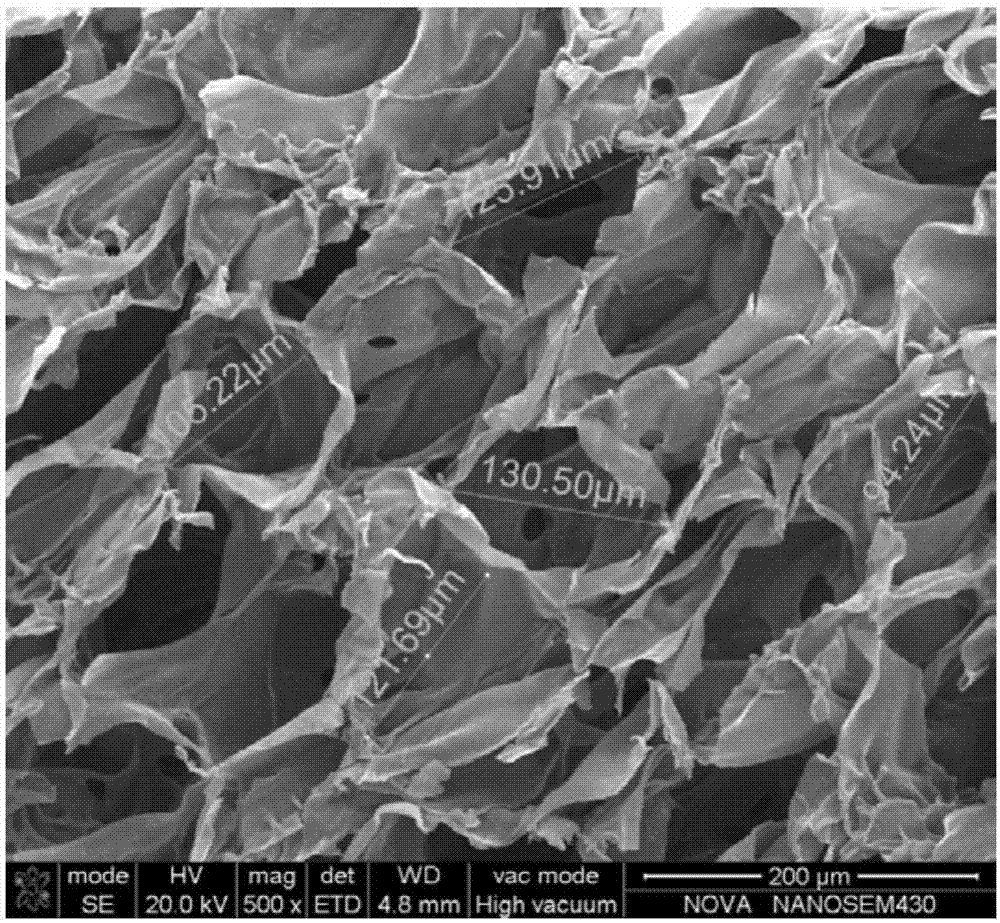

Embodiment 1

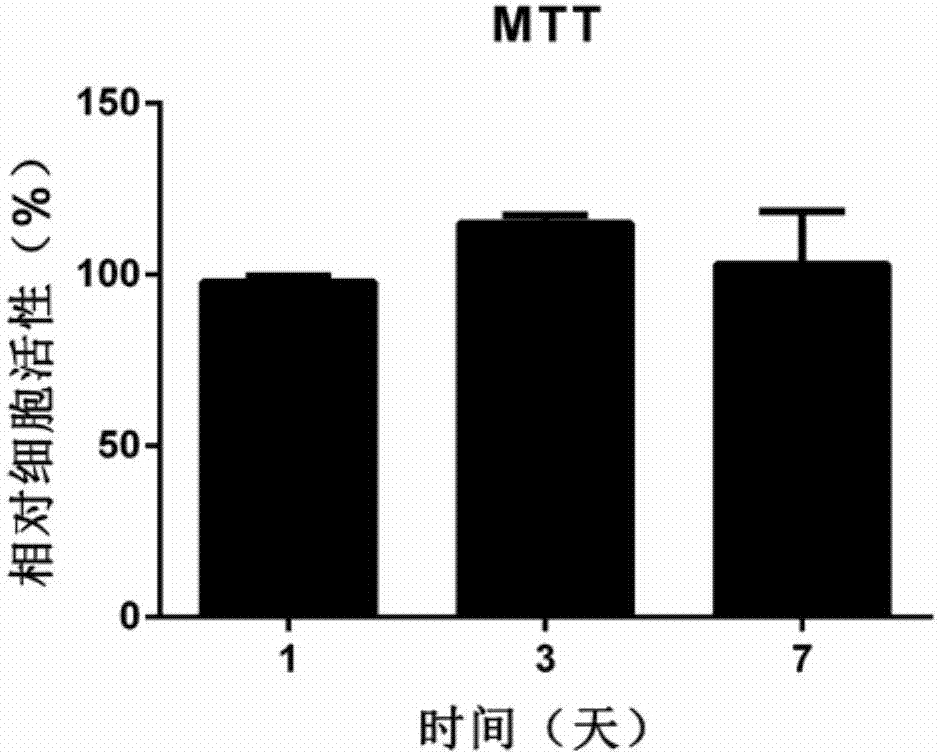

[0037] Prepare 10 mL of nano-copper solution with a concentration of 10 mM in ultrapure water, and stir with a magnetic stirrer at room temperature until uniform. Gradually add 150 mg of carboxymethyl chitosan and 150 mg of sodium alginate, and stir with a magnetic stirrer at room temperature until completely dissolved. The above mixed solution was added to a 48-well culture plate, and placed in a -80°C refrigerator overnight. The 48-well plate was transferred to a lyophilizer for 48 h. Add 2% CaCl 2 The solution was cross-linked for 30 minutes, and washed three times with ultrapure water. Put it into a -80°C refrigerator and freeze it overnight, and use a freeze dryer to freeze-dry for 24 hours to obtain a scaffold, which is a copper-containing carboxymethyl chitosan-sodium alginate scaffold.

[0038] Combine the resulting bracket with 10 5 Fibroblasts L929 were co-cultured, the medium was discarded at 1, 3, and 5 days, and 10% MTT solution was added. After 4 hours, DMSO ...

Embodiment 2

[0044] Prepare 10mL nano-copper solution with a concentration of 1mM in ultrapure water, and stir with a magnetic stirrer at room temperature until uniform. Gradually add 150 mg of carboxymethyl chitosan and 150 mg of sodium alginate, and stir with a magnetic stirrer at room temperature until completely dissolved. The above mixed solution was added to a 48-well culture plate, and placed in a -80°C refrigerator overnight. The 48-well plate was transferred to a lyophilizer for 48 h. Add 2% CaCl 2 The solution was cross-linked for 30 minutes, and washed three times with ultrapure water. Put it into a -80°C refrigerator and freeze it overnight, and use a freeze dryer to freeze-dry for 24 hours to obtain a scaffold, which is a copper-containing carboxymethyl chitosan-sodium alginate scaffold.

[0045] Compared with the blank culture plate, the copper-containing carboxymethyl chitosan-sodium alginate scaffold prepared in this example had relative cell viability of 85.81%, 132.19%...

Embodiment 3

[0049] Prepare 10mL nano-copper solution with a concentration of 0.1mM in ultrapure water, and stir with a magnetic stirrer at room temperature until uniform. Gradually add 150 mg of carboxymethyl chitosan and 150 mg of sodium alginate, and stir with a magnetic stirrer at room temperature until completely dissolved. The above mixed solution was added to a 48-well culture plate, and placed in a -80°C refrigerator overnight. The 48-well plate was transferred to a lyophilizer for 48 h. Add 2% CaCl 2 The solution was cross-linked for 30 minutes, and washed three times with ultrapure water. Put it into a -80°C refrigerator and freeze it overnight, and use a freeze dryer to freeze-dry for 24 hours to obtain a scaffold, which is a copper-containing carboxymethyl chitosan-sodium alginate scaffold.

[0050] Compared with the blank culture plate, the copper-containing carboxymethyl chitosan-sodium alginate scaffold prepared in this example had relative cell viability of 94.97%, 133.8...

PUM

| Property | Measurement | Unit |

|---|---|---|

| antibacterial rate | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com