Bionic manipulator able to climb and operate

A bionic climbable, robotic arm technology, applied in the field of robotic arms, to facilitate upgrades, reduce launch costs, and achieve precise motion positioning and output torque requirements.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

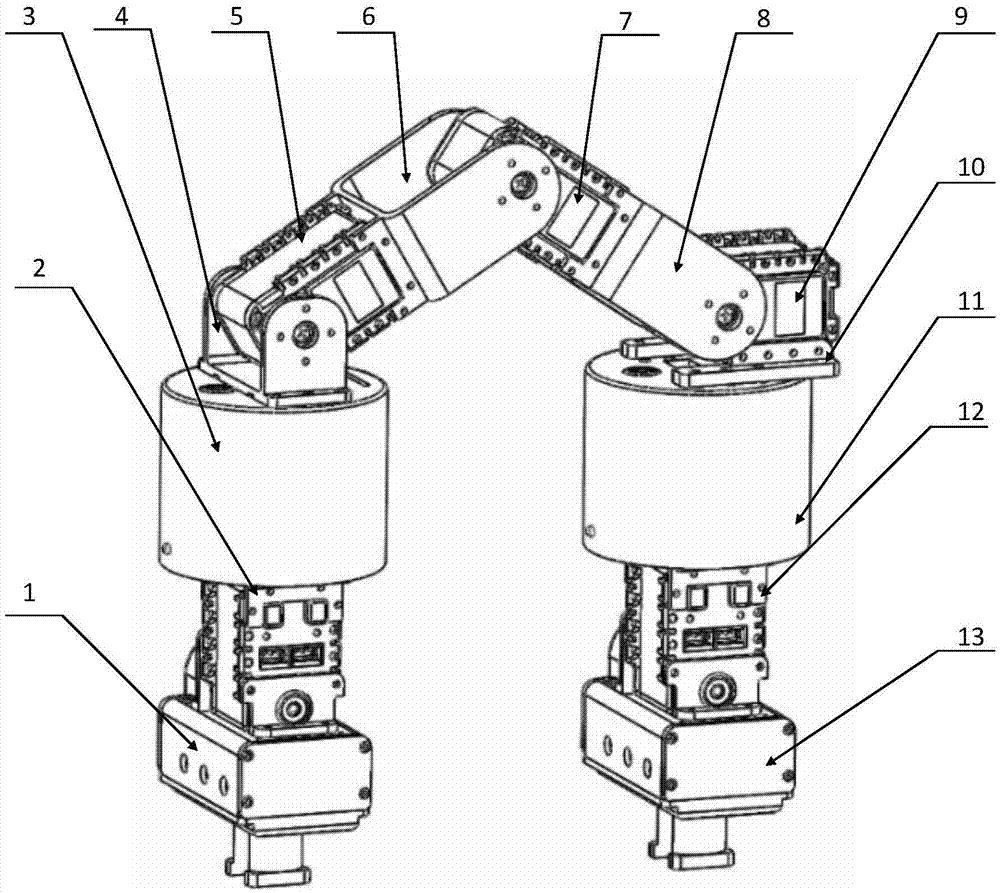

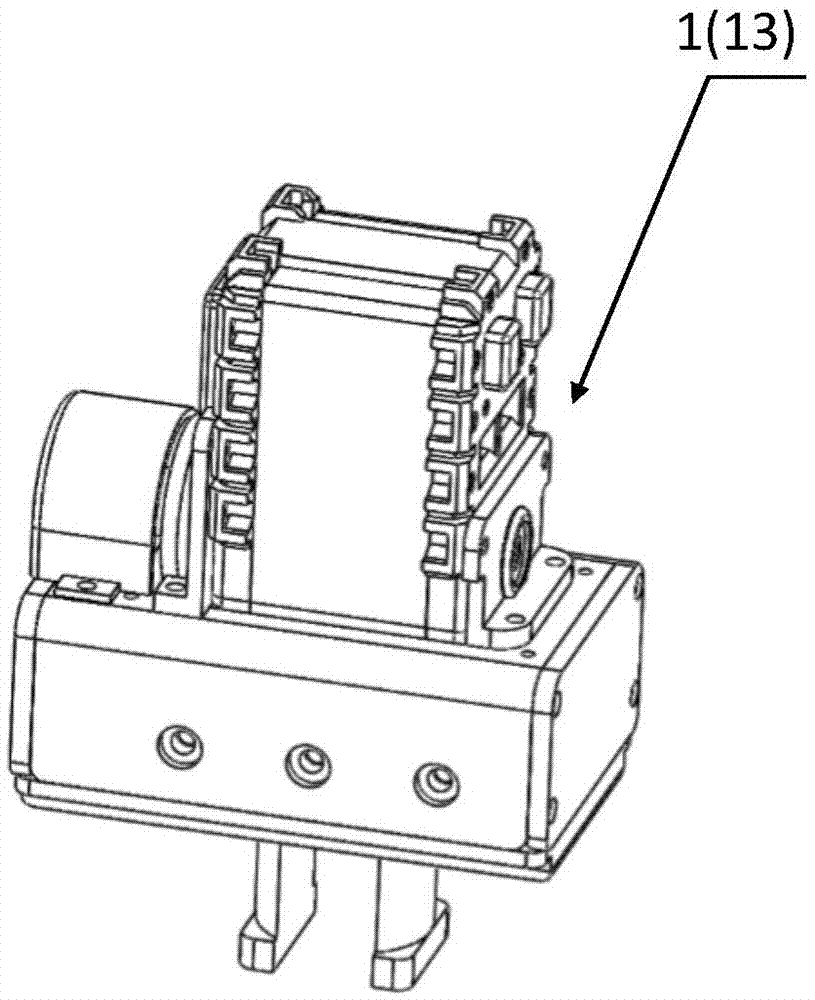

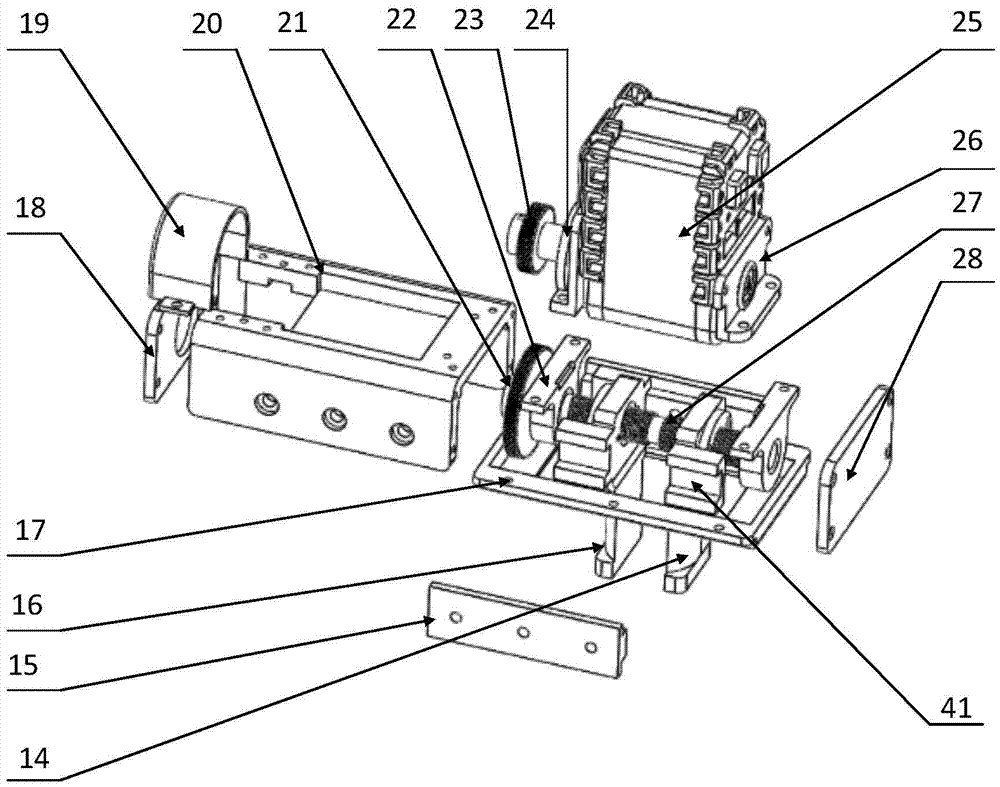

[0035] The mechanical arm of the present invention is a serial symmetrical configuration robot with clamping joint modules at both ends and five degrees of freedom in the middle. The five degrees of freedom are two rotation degrees of freedom and three flipping degrees of freedom. Such as figure 1 As shown, the present invention includes the first clamping joint module 1, the first rotary joint module 3, the first pitching joint servo motor 5, the second pitching joint servo motor 7, the third pitching joint servo motor 9, the second The rotary joint module 11 and the second clamping joint module 13, the first rotary joint module 3 is connected to the first clamping joint module 1 through the first clamping joint connecting rod 2, and the output end of the first pitch joint servo motor 5 passes through The rotary joint link 4 is connected to the first rotary j...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com