Method for preparing foam liquid and porous ceramic filtering material by utilizing residual sludge

A technology of excess sludge and porous ceramics, which is applied in the field of environmental technology and building materials, can solve the problems of limited heavy metal treatment capacity and limited sludge volume, and achieve good economic and environmental benefits, low cost and simple process.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

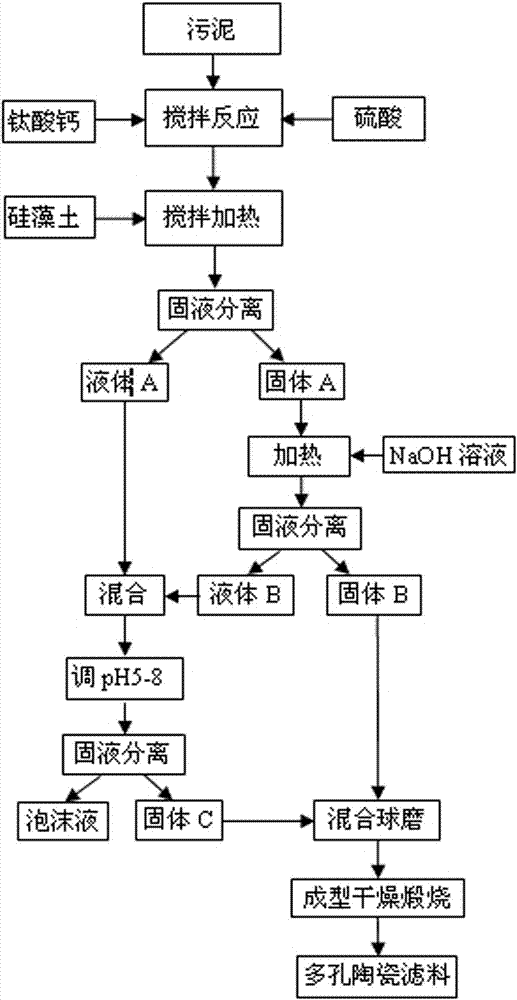

Method used

Image

Examples

Embodiment 1

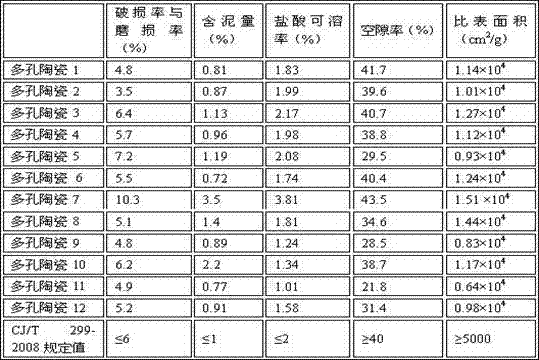

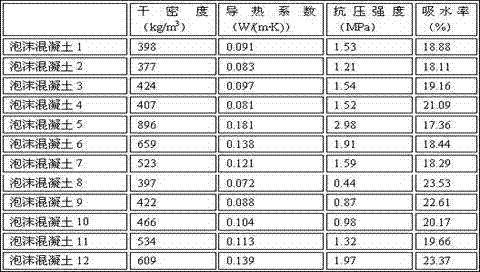

[0017] A method for preparing foam liquid and porous ceramic filter material from excess sludge is to take 2000g of fresh excess sludge with a water content of 82%, add 2000g of 0.2mol / L sulfuric acid solution and 100g of nanometer calcium titanate powder solid, stirred and reacted for 30 minutes, then added 400g of diatomaceous earth, stirred evenly, heated to keep a slight boiling reaction for 20 minutes, cooled to room temperature, left to react for 12 hours, and filtered with suction to obtain liquid A and solid A; (2) the solid Wash A with water until it is neutral, add a sodium hydroxide solution equal to the mass of solid A with a concentration of 0.2 mol / L, mix well, heat and keep a slight boil for 30 minutes, cool to room temperature, and filter with suction to obtain liquid B and solid B, and liquid A Mix with liquid B, stir and react completely, adjust the pH value to 6 with sulfuric acid solution and sodium hydroxide solution, let it stand for 12 hours, and filter w...

Embodiment 2

[0019] A kind of method that utilizes excess sludge to prepare foam liquid and porous ceramic filter material is to take fresh excess sludge with a moisture content of 82% 2000g, add 2000g of 0.2mol / L sulfuric acid solution and 20g of nanometer calcium titanate powder solid, stirred for 20 minutes, then added 200g of diatomaceous earth, stirred evenly, heated to keep a slight boiling reaction for 15 minutes, cooled to room temperature, left to react for 12 hours, and filtered to obtain liquid A and solid A; (2) the solid Wash A with water to neutrality, add a 0.2 mol / L sodium hydroxide solution with the same mass as solid A, mix well, heat and keep boiling slightly for 60 minutes, cool to room temperature, and suction filter to obtain liquid B and solid B, and dissolve the liquid Mix A and liquid B, stir and react completely, adjust the pH value to 7 with sulfuric acid solution and sodium hydroxide solution, and after standing for 12 hours, filter with suction to obtain solid C...

Embodiment 3

[0021] A kind of method that utilizes excess sludge to prepare foam liquid and porous ceramic filter material is to take fresh excess sludge with a moisture content of 82% 2000g, add 2000g of 0.2mol / L sulfuric acid solution and 20g of nanometer calcium titanate powder solid, stirred and reacted for 60 minutes, then added 1000g of diatomaceous earth, stirred evenly, heated to keep a slight boiling reaction for 60 minutes, cooled to room temperature, left to react for 12 hours, and filtered to obtain liquid A and solid A; (2) the solid Wash A with water until it is neutral, add 1.2 times the mass of solid A in a sodium hydroxide solution with a concentration of 0.2mol / L, mix well, heat and keep boiling slightly for 15 minutes, cool to room temperature, and suction filter to obtain liquid B and solid B. Mix A and liquid B, stir and react completely, adjust the pH value to 6 with sulfuric acid solution and sodium hydroxide solution, and after standing for 12 hours, filter with suct...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com