A vulcanizate and method for preparing vulcanized products using the vulcanizate

A vulcanized rubber and pre-vulcanized technology, which is applied in the direction of coating, etc., can solve the problems of uneven color distribution, difficult dispersion of pigments, and different shades of rubber product surface

Active Publication Date: 2018-11-30

上海金香乳胶制品有限公司

View PDF3 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

[0004] However, in the above-mentioned technical scheme, the pigment is not easy to disperse, so the color distribution is uneven, so that the color of the surface of the rubber product produced is not uniform.

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment 1

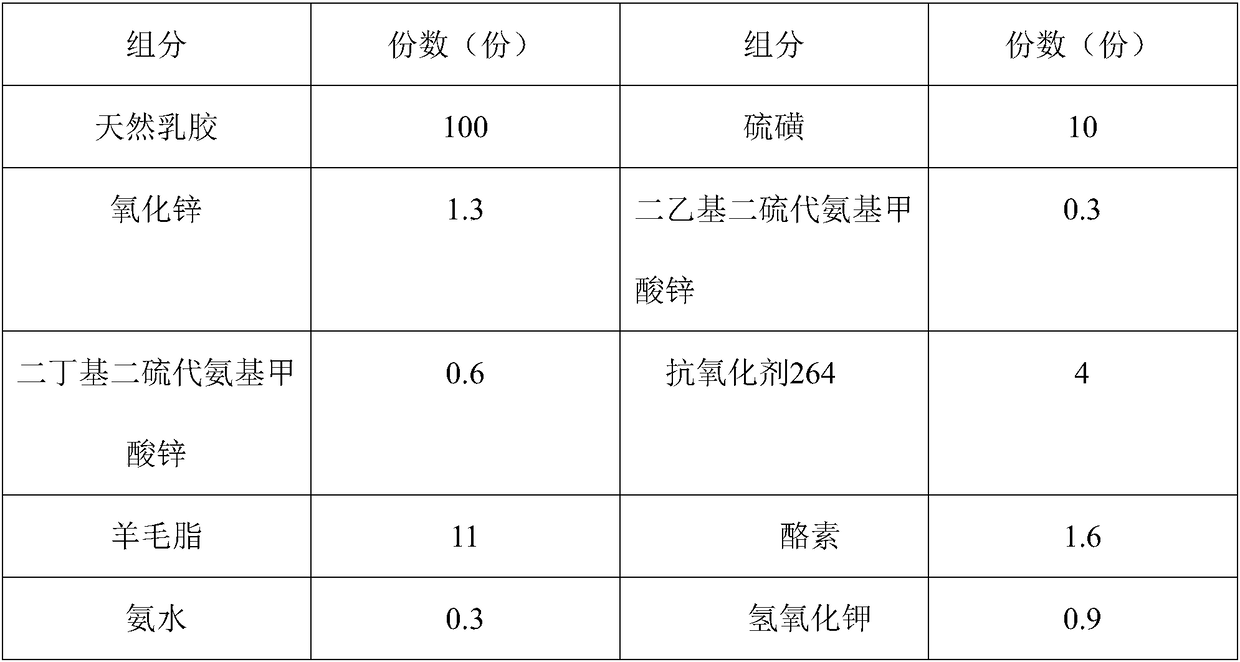

[0025] Table 1 Components and parts by weight of a vulcanizate

[0026]

[0027]

Embodiment 2

[0029] Table 2 Components and parts by weight of a vulcanizate

[0030] components

Embodiment 3

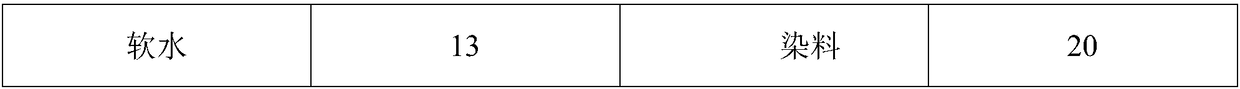

[0032] Table 3 Components and parts by weight of a vulcanizate

[0033]

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

The invention discloses vulcanized rubber and a method for preparing a vulcanized product by utilizing the vulcanized rubber. The vulcanized rubber comprises the following components in parts by weight: 80-120 parts of natural emulsion, 8-20 parts of sulphur, 0.8-1.5 parts of zinc oxide, 0.8-1.5 parts of accelerant, 4-10 parts of antioxidant, 11-25 parts of wool fat, 0.8-2.4 parts of casein, 0.2-0.8 part of ammonium hydroxide, 0.5-1.5 parts of potassium hydroxide, 8-13 parts of soft water, 18-25 parts of dye and 5-15 parts of leveling agent. According to the invention, the dye can disperse in formula components through the leveling agent, so that the effects of uniform distribution and uniform color of acquired vulcanized product are achieved.

Description

technical field [0001] The invention relates to the technical field of solid rubber processing, in particular to a vulcanized rubber and a method for preparing vulcanized products using the vulcanized rubber. Background technique [0002] Latex is widely used in various crafts and industrial production, especially in European and American holiday gifts such as masks, headgear, cartoon characters and various toys. The traditional technology of latex production is natural latex plus some accelerators and pigments. [0003] For example, the invention patent with publication number CN104327321A discloses a latex in the market, and its components are: 100 parts of natural latex, 0.4 part of zinc oxide, 2.5 parts of solid paraffin, 0.5 part of casein, 0.4 part of potassium hydroxide, accelerator PX. .8 parts, anti-aging agent DBH 3 parts, sulfur 5 parts, pigment 3 parts, a total of 115.6 parts, the technical conditions are total solid content 50%-52%, chloroform value 2, viscosit...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C08L7/02C08L91/00C08L89/00C08L71/02C08K13/02C08K3/22C08K5/544C08K5/39B29C45/00B29C35/02

CPCB29C35/02B29C45/00C08K2201/011C08K2201/014C08L7/02C08L2205/035C08L91/00C08L89/00C08L71/02C08K13/02C08K2003/2241C08K5/544C08K5/39C08K2003/2296

Inventor 付离疆

Owner 上海金香乳胶制品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com