High-voltage electromagnetic valve state detection device and high-voltage electromagnetic valve state detection method

A state detection device, high-voltage solenoid valve technology, applied in the direction of measuring devices, circuit breaker testing, measuring electricity, etc., can solve the problems that pressure fluctuations cannot be maintained, the main steam isolation valve is closed, and the oil pump is frequently started, etc., to ensure pressure, The effect of ensuring authenticity, improving exhaust efficiency and stabilizing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

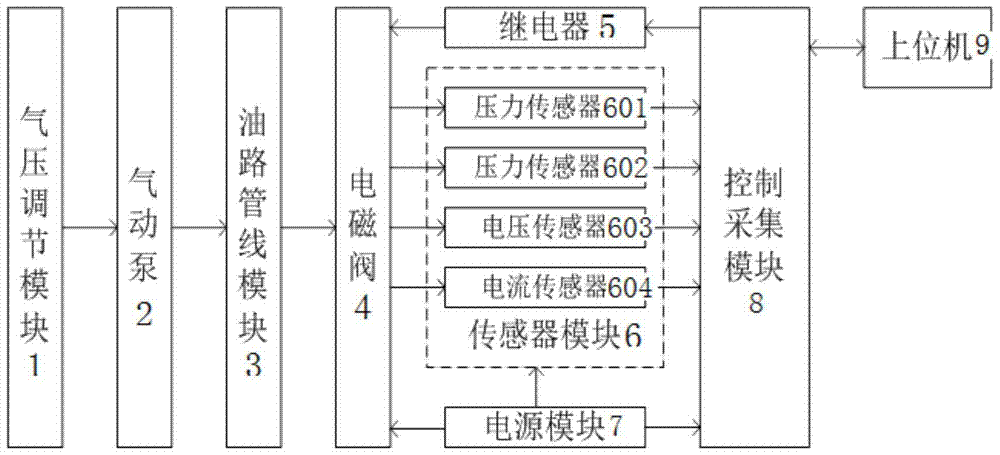

[0018] A high-pressure solenoid valve state detection device

[0019] Including the air pressure adjustment module 1, the air pressure adjustment module 1 is connected with the pneumatic pump 2, the air pressure adjustment module 1 provides the working air source for the air pump 2, and the pressure of the air source can be adjusted; the air pressure pump 2 is connected with the oil pipeline module 3, and the air pump 2 Provide oil pressure for the oil pipeline module 3; the oil pipeline module 3 is connected to the solenoid valve 4, the solenoid valve 4 includes an inlet and a discharge port, and the oil pipeline module 3 provides specified oil pressure for the inlet and discharge port of the solenoid valve 4; the solenoid valve 4 is the test object, which is connected with the relay 5, the sensor module 6, and the power module 7 respectively, wherein the power module 7 provides power for the solenoid valve 4, the sensor module 6, and the control acquisition module 8 respectiv...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com