Fast controllable polarizer for high-power electron cyclotron resonance heating system

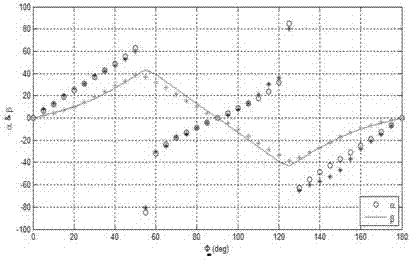

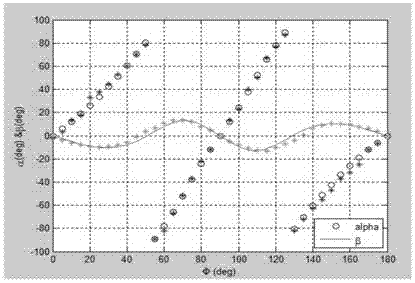

An electron cyclotron resonance and heating system technology, applied in the microwave field, can solve the problems of low positioning accuracy, inability to efficiently couple, and the inability to use the electronic cyclotron vacuum transmission system, etc., to achieve high positioning accuracy and fast rotation control.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

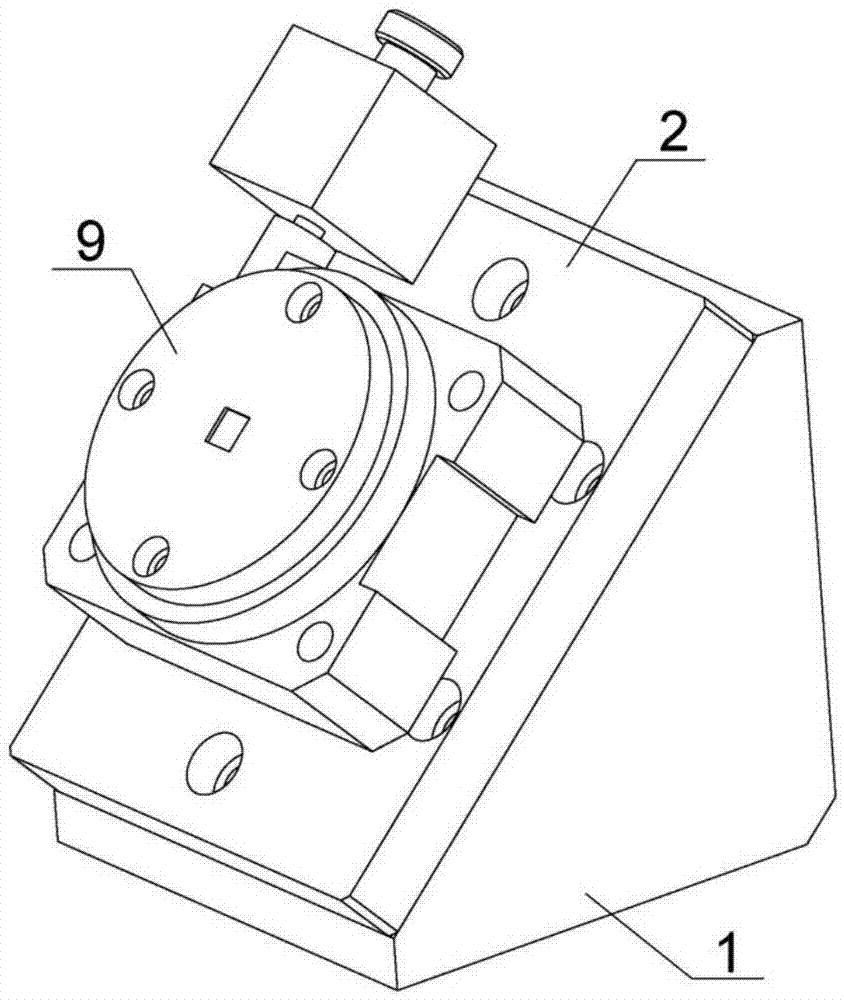

[0055] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

[0056] Such as Figure 1 to Figure 4 As shown, a fast controllable polarizer for a high-power electron cyclotron resonance heating system of the present invention includes: a microwave reversing elbow 1, a mounting substrate 2, a polarizing mirror 3, a static sealing O-ring 4, and a dynamic sealing O-ring Ring 5, supporting bearing 6, bearing seat 7, rotating shaft 8, rotating platform 9, coupling 10, motor 11, emergency manual adjustment device 12, 13-turbine, 14-worm;

[0057] The microwave reversing elbow 1 is connected with the electronic cyclotron transmission system, and is used to transmit high-power microwaves to achieve 90-degree reversing of the microwave transmission direction; comprehensively considering the loss of the reversing elbow, the microwave reversing elbow 1 is integrated type reversing elbow, that is, the input and out...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com