Emitting organic laser thin film device equipped with gold nanoparticle enhanced light pumped surface and application and preparation method thereof

A gold nanoparticle and laser thin film technology, which is applied in the field of lasers, can solve the problems of not fully utilizing organic semiconductor laser devices, and achieve the effects of simple and fast preparation methods, lower hole injection barriers, and lower threshold values

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

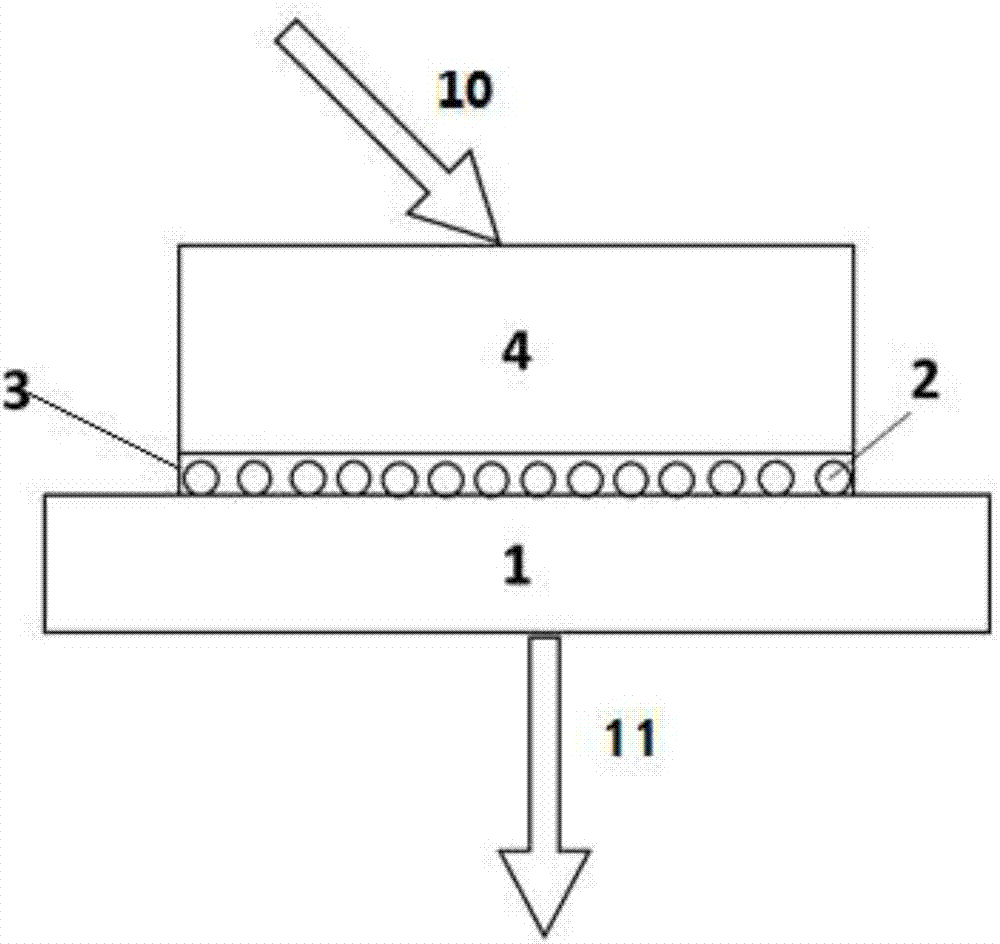

[0057] In this example, see figure 1 , an organic laser emitting thin film device sample 1 with a gold nanoparticle-enhanced optical pumping surface, mainly composed of a substrate 1 and a gain medium layer 4, and an enhanced laser radiation is also arranged between the substrate 1 and the gain medium layer 4 Composite film, specifically:

[0058] On the surface of the substrate 1, there is a discontinuous film of discrete particles formed by gold nanoparticles 2 that cannot conduct overall lateral conduction, and an uneven film of discrete particles formed by gold nanoparticles 2 and the gain medium layer 4 is provided. The film of the spacer layer 3, that is, between the substrate 1 and the gain medium layer 4, the enhanced laser radiation composite film formed by the discrete particle film of gold nanoparticles 2 and the thin film of the spacer layer 3 is set; The gold in the thin film forms isolated particles or aggregates of fragmented particles; the spacer layer 3 is ma...

Embodiment 2

[0082] This embodiment is basically the same as Embodiment 1, especially in that:

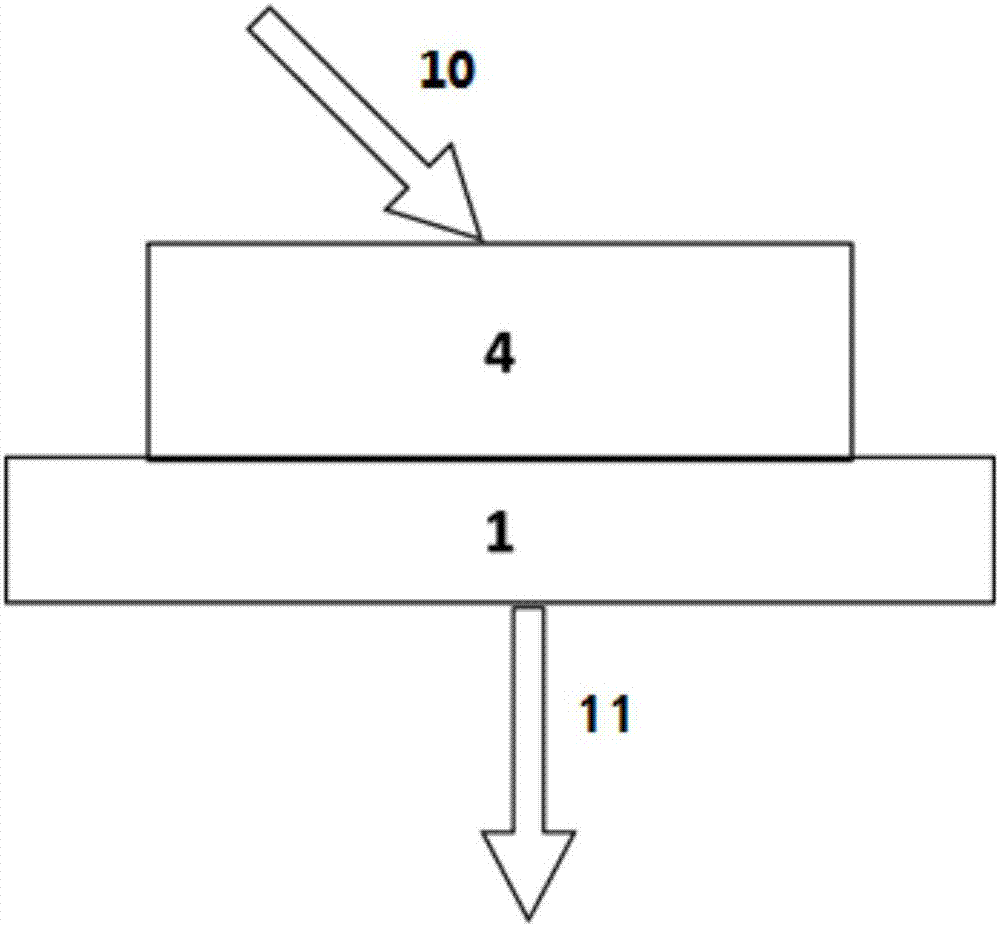

[0083] In this embodiment, a sample 2 of an emitting organic laser thin film device with an optically pumped surface enhanced by gold nanoparticles is mainly composed of a substrate 1 and a gain medium layer 4, between the substrate 1 and the gain medium layer 4 Also set enhanced laser radiation composite film, specifically:

[0084] On the surface of the substrate 1, there is a discontinuous film of discrete particles of gold nanoparticles 2 formed by gold nanoparticles 2 that cannot conduct overall lateral conduction, and between the film of discrete particles formed of gold nanoparticles 2 and the gain medium layer 4 A non-flat spacer layer 3 film is arranged between them, that is, between the substrate 1 and the gain medium layer 4, a laser radiation-enhancing composite film formed by laminating the discrete particle film of gold nanoparticles 2 and the film of the spacer layer 3 is arrange...

Embodiment 3

[0100] This embodiment is basically the same as the previous embodiment, and the special features are:

[0101] In this embodiment, a thin-film emitting organic laser device sample 4 with a gold nanoparticle-enhanced optical pumping surface is mainly composed of a substrate 1 and a gain medium layer 4, between the substrate 1 and the gain medium layer 4 Also set enhanced laser radiation composite film, specifically:

[0102] The discrete particle film of gold nanoparticle 2 is the same as embodiment one, and the material of spacer layer 3 is selected Alq 3 .

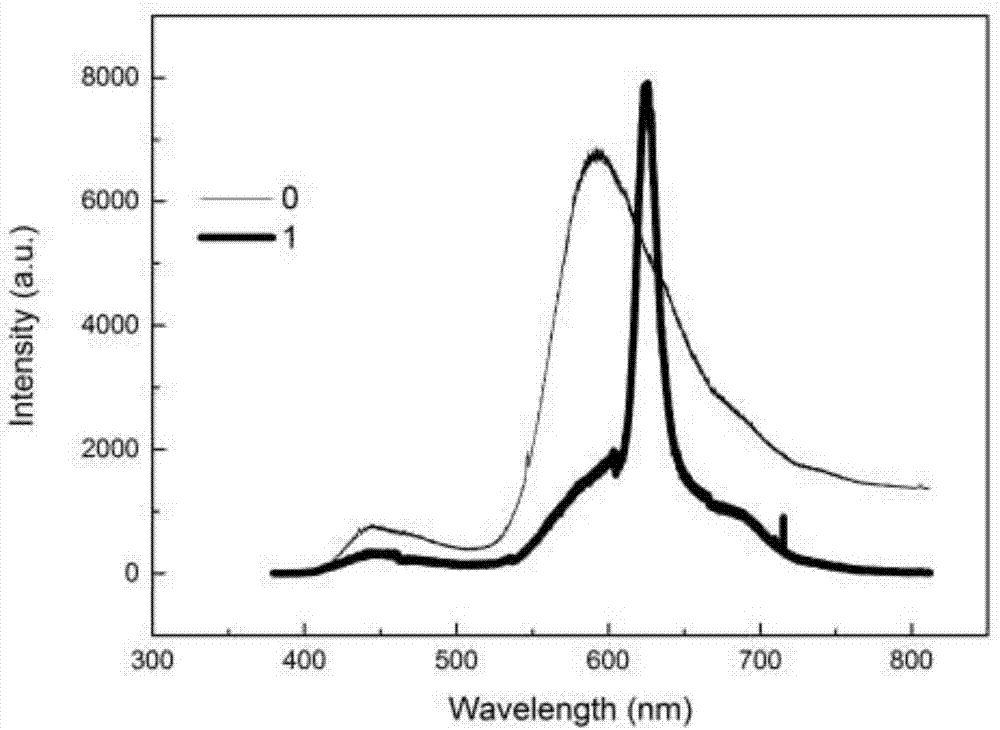

[0103] In this embodiment, the laser gain medium in the gain medium layer 4 is made of organic small molecule host-guest material, and its host material is an organic small molecule material that can effectively absorb laser energy. The host in the gain medium layer 4 The material is 1,4-bis[N-(1-naphthyl)-N'-phenylamino]-4,4'diamine, 1,4-bis[2-[4-[N,N-di(p-tolyl) amino]phenyl]vinyl]benzene and tris-(8-hydroxyquinolin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com