Optical fiber holding apparatus and fiber laser processing apparatus

A holding device and optical fiber technology, applied in lasers, laser welding equipment, laser parts, etc., can solve the problems of optical fiber degradation, fluctuation of laser oscillation characteristics, damage, etc., to reduce deterioration and damage, improve laser characteristics, and maintain performance. and the effect of heat dissipation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] Preferred embodiments of the present invention will now be described with reference to the accompanying drawings.

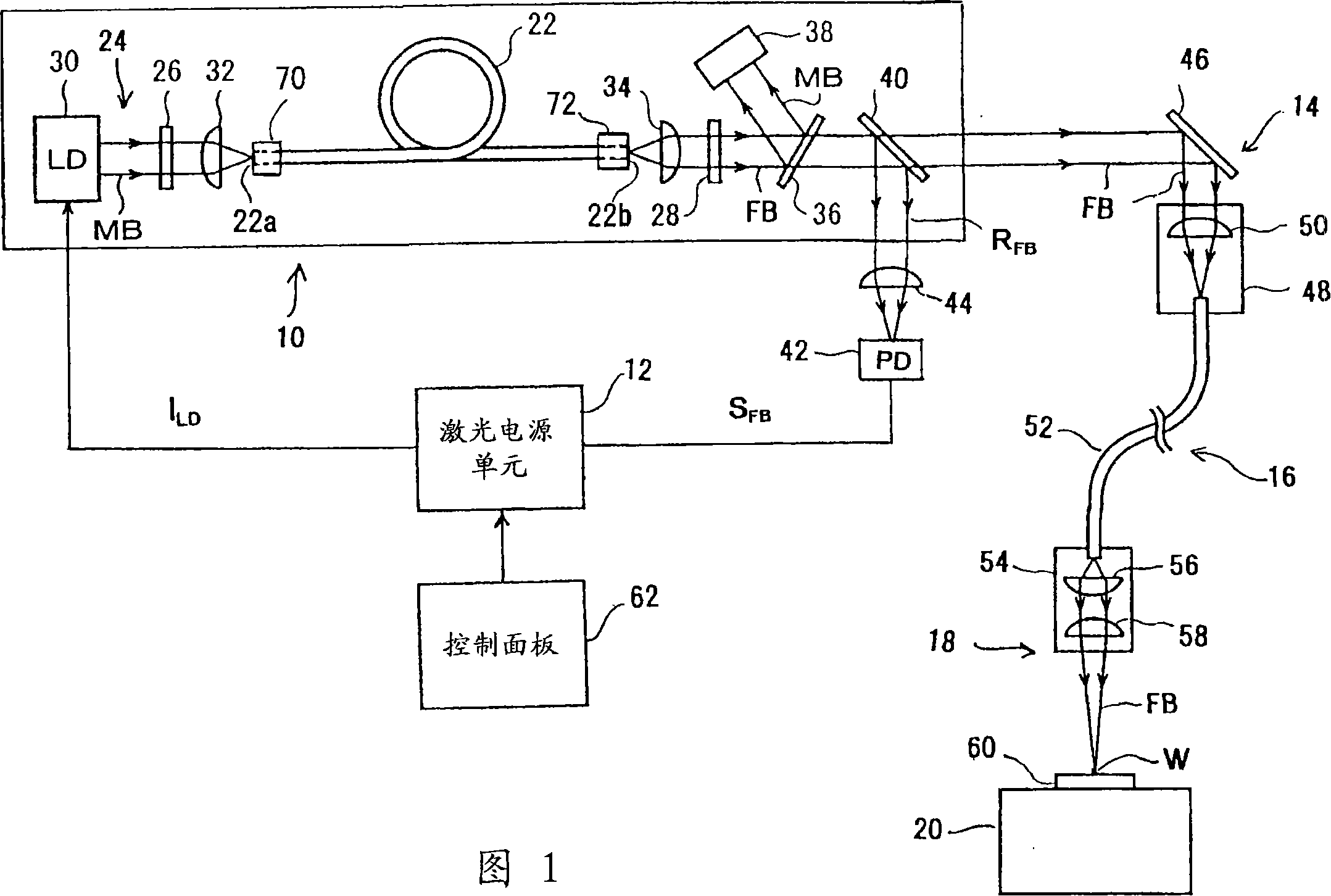

[0029] FIG. 1 shows the configuration of a fiber laser processing apparatus according to one embodiment of the present invention. The fiber laser processing device includes a fiber laser oscillator 10 , a laser power supply unit 12 , a laser incident unit 14 , an optical fiber transmission system 16 , a laser emitting unit 18 and a processing table 20 .

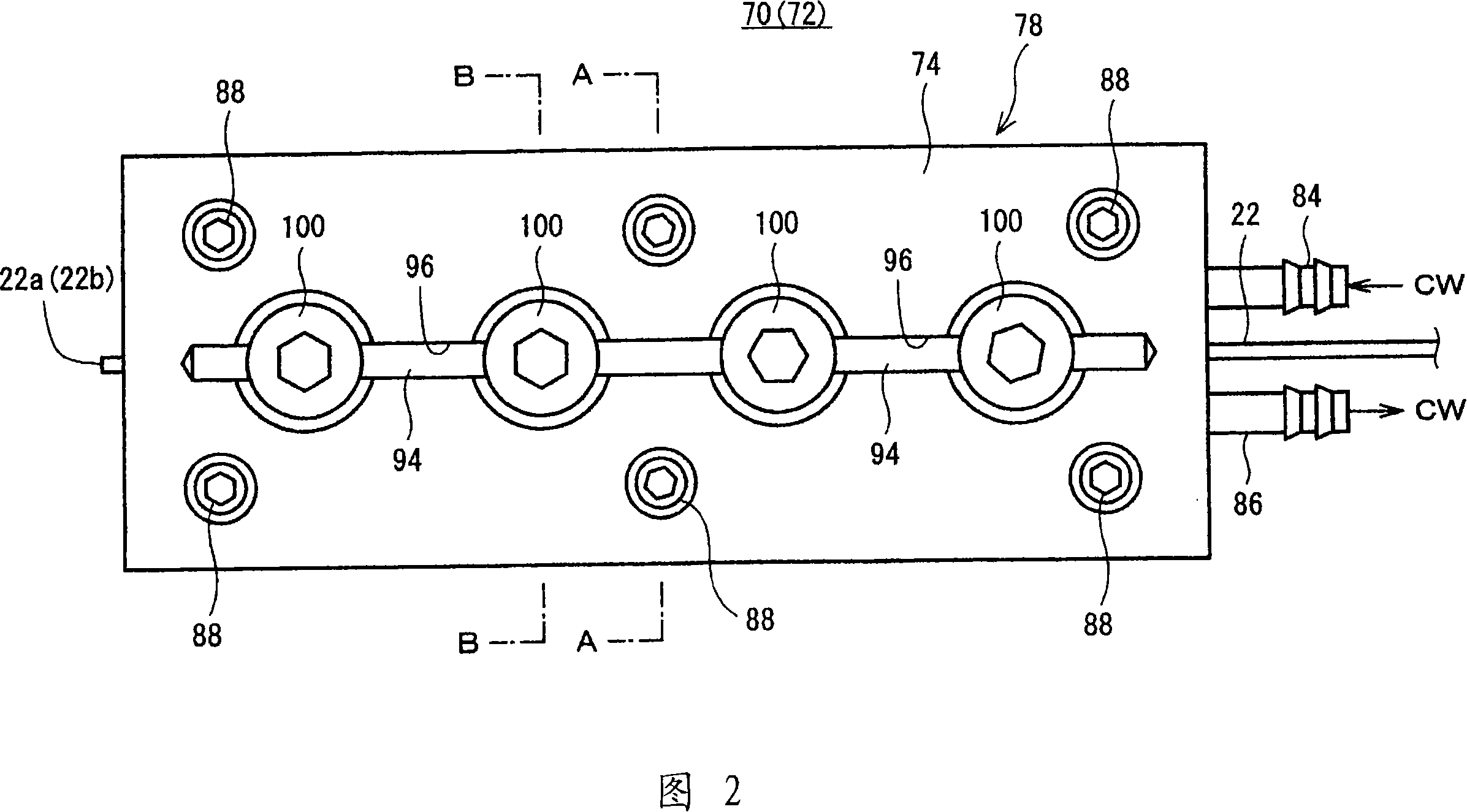

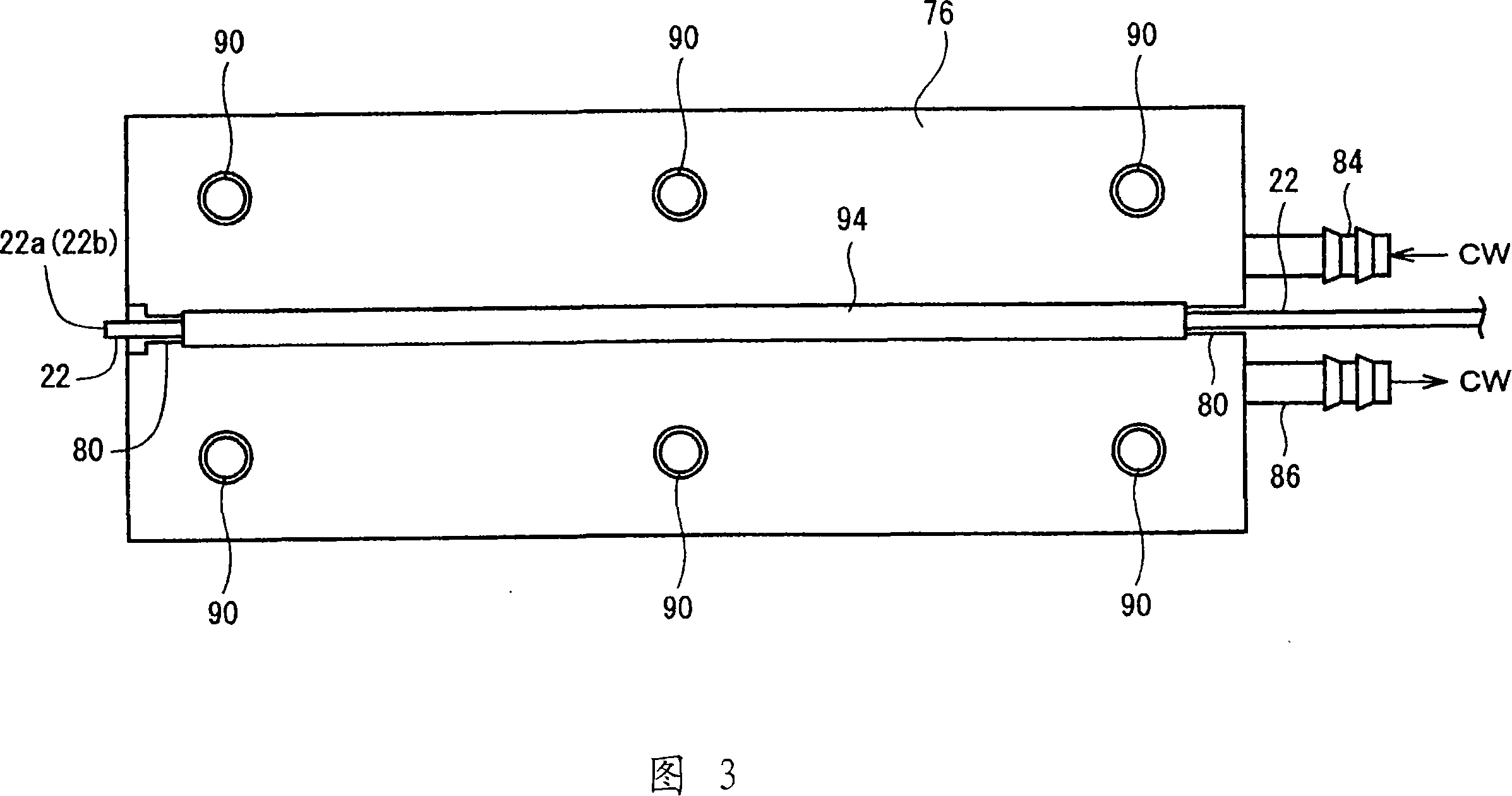

[0030] The fiber laser oscillator 10 has an oscillating fiber (hereinafter referred to as "oscillating fiber") 22, a photoelectric excitation unit 24 that sends excitation light MB excited to the end face of the oscillating fiber 22, and a pair of optically opposite optical fibers on both sides of the oscillating fiber 22. Optical resonator mirrors 26 and 28 . Both ends of the oscillation fiber 22 are held by fiber holders 70 and 72, respectively. The fiber holders 70 and 72 constitute the fiber holder ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com