Grain combine harvester material feeding system and splitting treatment method

A combine harvester and processing method technology, applied to harvesters, cutters, agricultural machinery and implements, etc., can solve the problems of occupying machine space and mechanical energy, low utilization rate of mechanical energy, waste of manpower and material resources, etc., to save management costs, The effect of reducing manpower and material cost and reducing waste

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

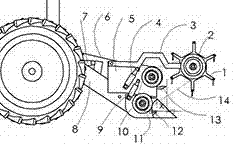

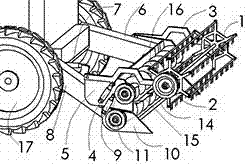

[0013] The material feeding system of the grain combine harvester is located at the front part of the harvester front wheel 17, and the upper auger assembly is composed of the upper auger screw blade 16 and the auger driving pulley 11, and is connected with the upper cutting platform 5 and the upper cutting platform 5. The upper cutting knife assembly 13 and the left material conveyor 6 jointly constitute the upper material harvesting and feeding system, and the lower auger assembly is composed of the lower auger screw blade 15 and the auger driving pulley 11, and is connected with the lower cutting platform 10, the lower auger The lower cutting knife assembly 12 on the lower edge of the header 10 and the right material conveyor 8 jointly constitute the lower material harvesting and feeding system, which consists of a reel 1, a reel drive pulley 2, and a reel support rod 3. The wheel assembly and the upper and lower material harvesting feeding system constitute the grain combin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com