A real stone paint suitable for airless spraying

A technology of airless spraying and real stone paint, applied in the field of coatings, can solve the problems of difficulty in guaranteeing coating quality, fast spraying speed, and excessive sand loss, etc., and achieve the effects of shortening the construction period, avoiding waste, and simple and convenient preparation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

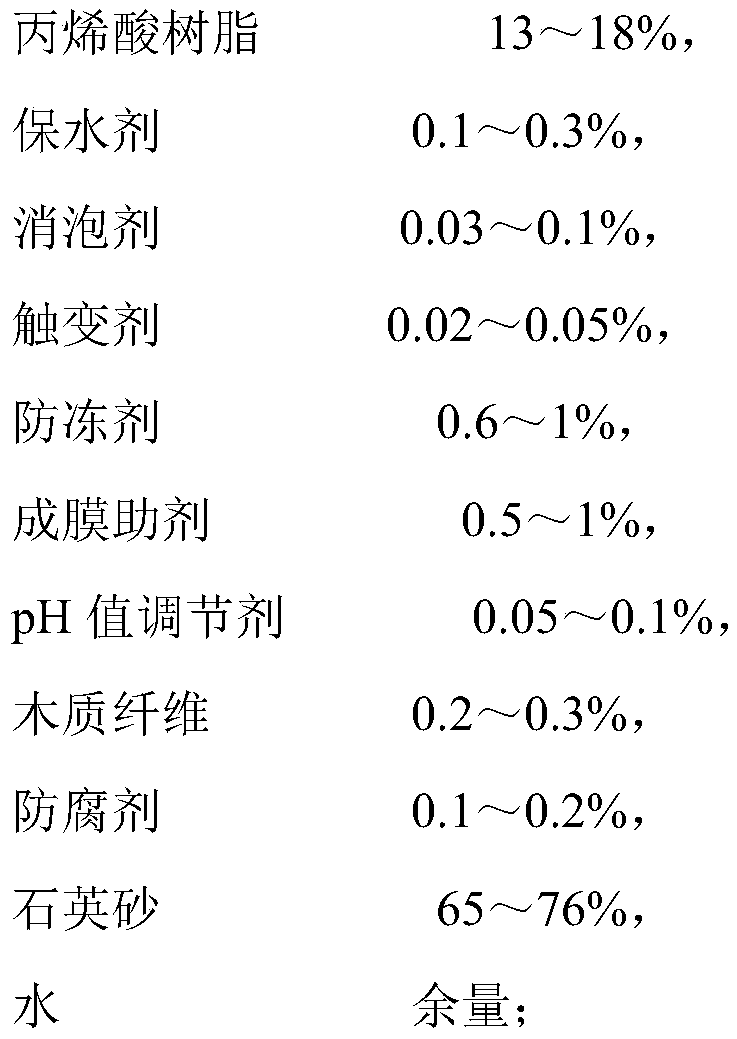

[0027] Aiming at the disadvantages of coating cracking and high sand loss rate caused by airless spraying in the prior art, the present invention provides a real stone paint suitable for airless spraying, which is made by mixing the following components by weight percentage: acrylic acid Resin 13-18%, water-retaining agent 0.1-0.3%, defoamer 0.03-0.1%, thixotropic agent 0.02-0.05%, antifreeze 0.6-1%, film-forming aid 0.5-1%, pH regulator 0.05 ~0.1%, wood fiber 0.2~0.3%, preservative 0.1~0.2%, quartz sand 65~76%, and the balance is water.

[0028] The real stone paint that the present invention is applicable to airless spraying makes as follows:

[0029] Dissolve the water-retaining agent and thixotropic agent in the film-forming aid and antifreeze respectively according to the proportion of the components, and then add them to accurately measured water, stir, and then add acrylic resin and defoamer to the aqueous solution in sequence , preservative, wood fiber, pH regulator, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| minimum film forming temperature | aaaaa | aaaaa |

| solid content | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com