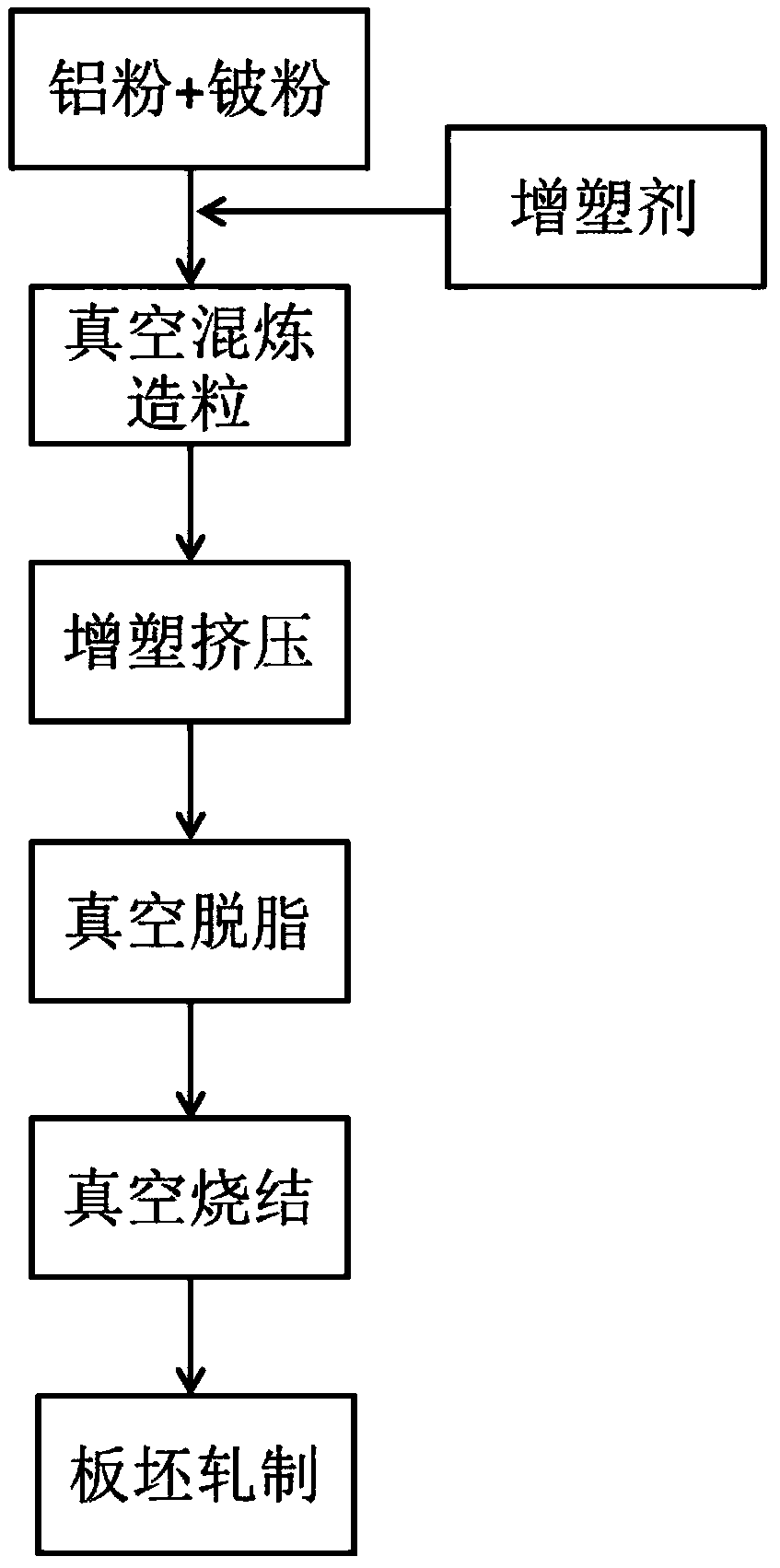

A preparation method for plasticized extrusion forming of deformed beryllium aluminum alloy plate

A technology of extrusion forming and beryllium aluminum alloy, which is applied in the field of plasticizing extrusion forming of deformed beryllium aluminum alloy plate, can solve the problems of specific gravity segregation and composition segregation of beryllium aluminum alloy plate, and achieves good performance, dense structure, and improved plasticity. The effect of deformability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Step 1: Ingredients

[0034] In the mixture of beryllium powder and aluminum powder, the mass percentage of beryllium is 40%, the rest is aluminum, and the plasticizer is paraffin. The mixture of beryllium powder and aluminum powder and plasticizer are mixed evenly under vacuum according to the ratio of 30:3. Obtain mixed raw materials, wherein the particle size of the metal powder is 250 mesh to 350 mesh;

[0035] Step 2: Mixing

[0036] The mixed raw materials are vacuum mixed in a vacuum mixing granulator, the mixing temperature is 30°C, and the mixing time is 20 minutes. After mixing, the vacuum mixing granulator performs granulation, and the particle size after granulation is 10mm. , the length is 20mm;

[0037] Step 3: Extrude the billet

[0038] In a vacuum state, put the granulated mixture into the plunger extruder of the flat extrusion cylinder for extrusion, and the constant temperature oven set in the extrusion cylinder and the mold keeps the temperature a...

Embodiment 2

[0044] Step 1: Ingredients

[0045] In the mixture of beryllium powder and aluminum powder, the mass percentage of beryllium is 50%, the rest is aluminum, and the plasticizer is paraffin. The mixture of beryllium powder and aluminum powder and plasticizer are mixed evenly under vacuum according to the ratio of 40:5. Obtain mixed raw materials, wherein the metal powder particle size is 300 mesh;

[0046] Step 2: Mixing

[0047] The mixed raw materials are vacuum mixed in a vacuum mixing granulator, the mixing temperature is 50°C, and the mixing time is 100min. After mixing, the vacuum mixing granulator performs granulation, and the particle size after granulation is 20mm , the length is 20mm;

[0048] Step 3: Extrude the billet

[0049] In a vacuum state, put the granulated mixture into the plunger extruder of the flat extrusion barrel for extrusion, and the constant temperature oven set in the extrusion barrel and the mold keeps the temperature at 70°C. The pressing speed ...

Embodiment 3

[0055] Step 1: Ingredients

[0056]In the mixture of beryllium powder and aluminum powder, the mass percentage of beryllium is 60%, the rest is aluminum, the plasticizer is paraffin, and the mixture of beryllium powder and aluminum powder and plasticizer are mixed evenly under vacuum according to the ratio of 50:8, Obtain mixed raw materials, wherein the metal powder particle size is 350 mesh;

[0057] Step 2: Mixing

[0058] The mixed raw materials are vacuum mixed in a vacuum mixing granulator, the mixing temperature is 80°C, and the mixing time is 200min. After mixing, the vacuum mixing granulator performs granulation, and the particle size after granulation is 30mm. , the length is 20mm;

[0059] Step 3: Extrude the billet

[0060] In a vacuum state, put the granulated mixture into the plunger extruder of the flat extrusion cylinder for extrusion, and the constant temperature oven set in the extrusion cylinder and the mold keeps the temperature at 80 ° C. The pressing ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| tensile strength | aaaaa | aaaaa |

| elastic modulus | aaaaa | aaaaa |

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com