Impeller washing machine and inner barrel thereof

A pulsator washing machine and inner cylinder technology, applied in the field of washing machines, can solve the problems of pulsator washing machine with large vibration, limited vibration damping effect, and poor user experience, and achieve the effects of avoiding fatigue failure, reducing cost, and reducing mechanical contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

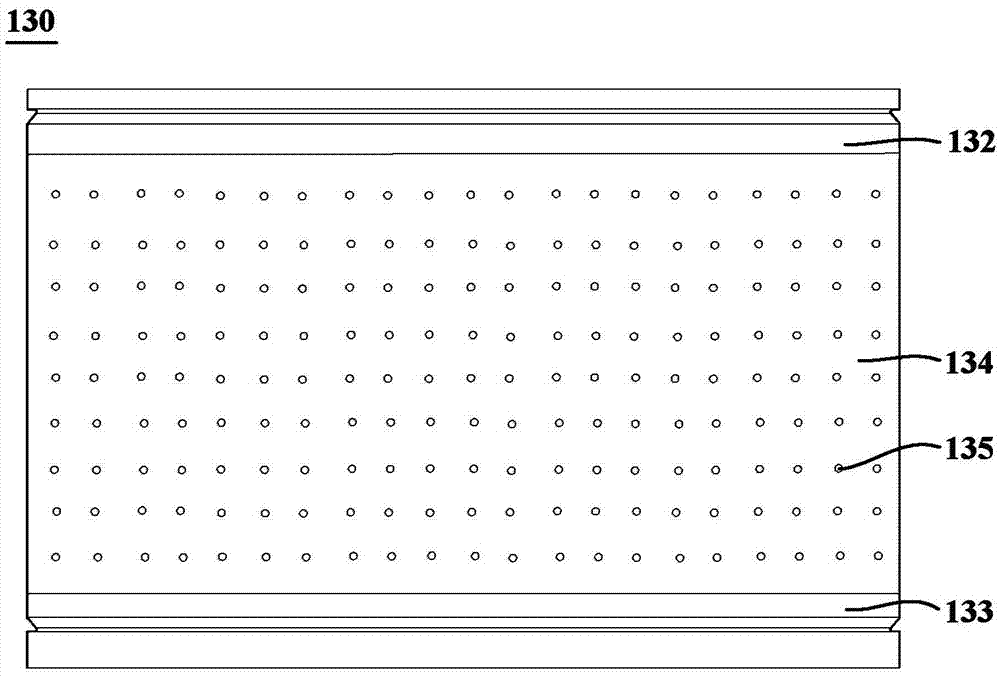

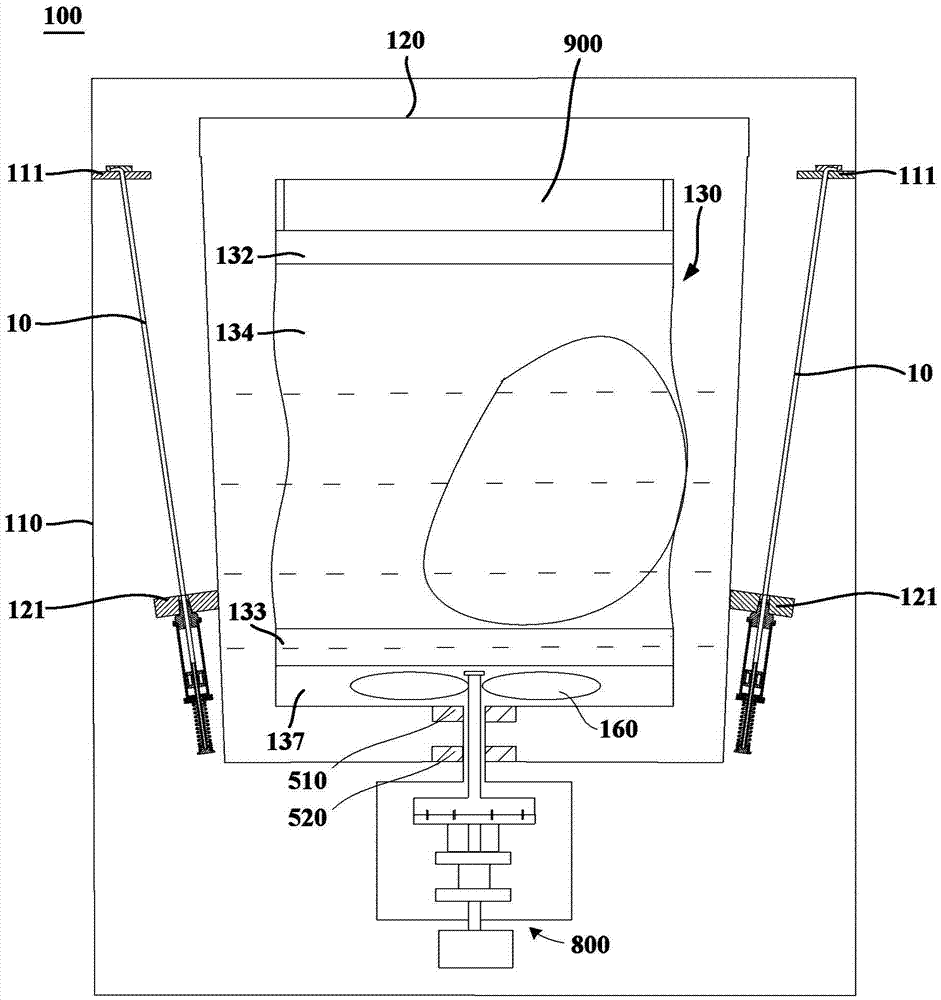

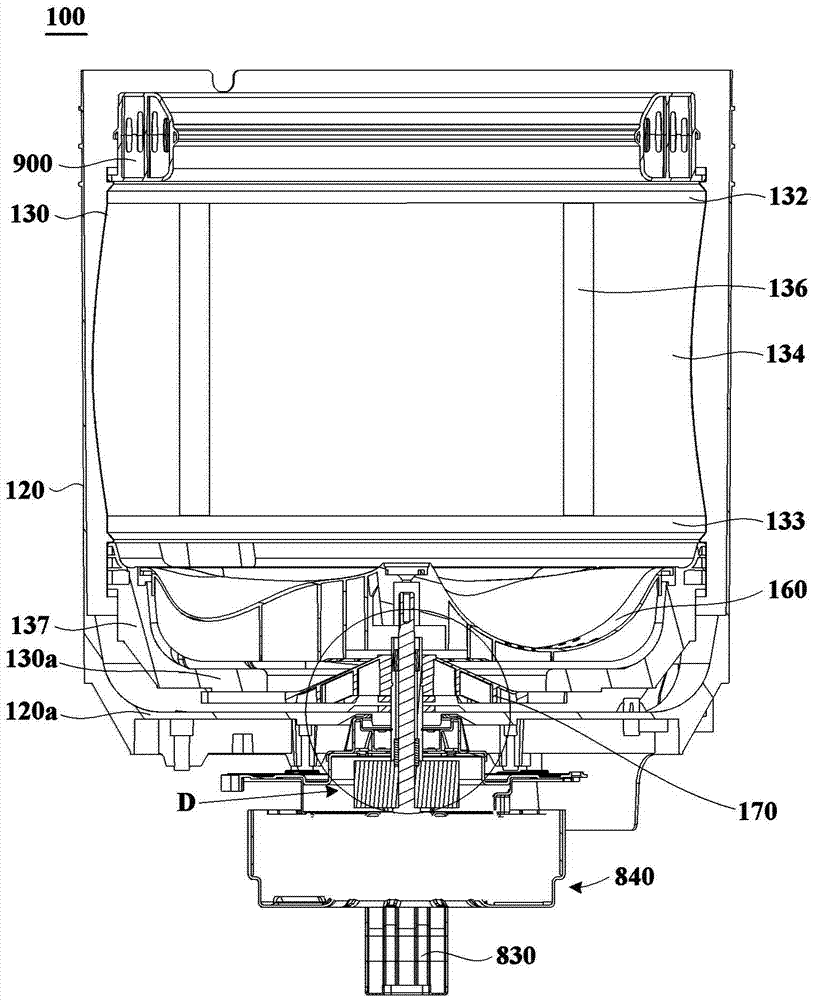

[0046] figure 1 is a schematic structural diagram of the inner tub 130 of the top-loading washing machine according to one embodiment of the present invention. see figure 1The inner cylinder 130 includes an upper cylinder wall 132 and a lower cylinder wall 133 made of rigid material, and a middle cylinder wall 134 connected between the upper cylinder wall 132 and the lower cylinder wall 133 and made of flexible material. The middle cylinder wall 134 is configured to deform under the eccentric load in the inner cylinder 130 when the inner cylinder 130 rotates at a high speed for dehydration, thereby reducing the eccentricity or degree of eccentricity of the load in the inner cylinder 130 .

[0047] Those skilled in the art can easily understand that for a pulsator washing machine, when the inner tub 130 rotates at a high speed for dehydration, eccentricity may occur due to uneven distribution of clothes in the inner tub 130 . For the top-loading washing machine with the inner...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com