A kind of internal combustion wave rotor with movable end cover and sealing method thereof

A technology of internal combustion wave rotor and mobile end, which is applied in the direction of gas turbine devices, machines/engines, jet propulsion devices, etc. It can solve the problems of rotor jamming, poor sealing effect between the end face and end cover of internal combustion wave rotors, etc., so as to ensure reliability , to avoid the rotor stuck, the effect of simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with the drawings.

[0025] Aiming at the problem of internal combustion wave rotor leakage, the present invention proposes a mobile end cover sealing device and method. The specific implementation process is as follows:

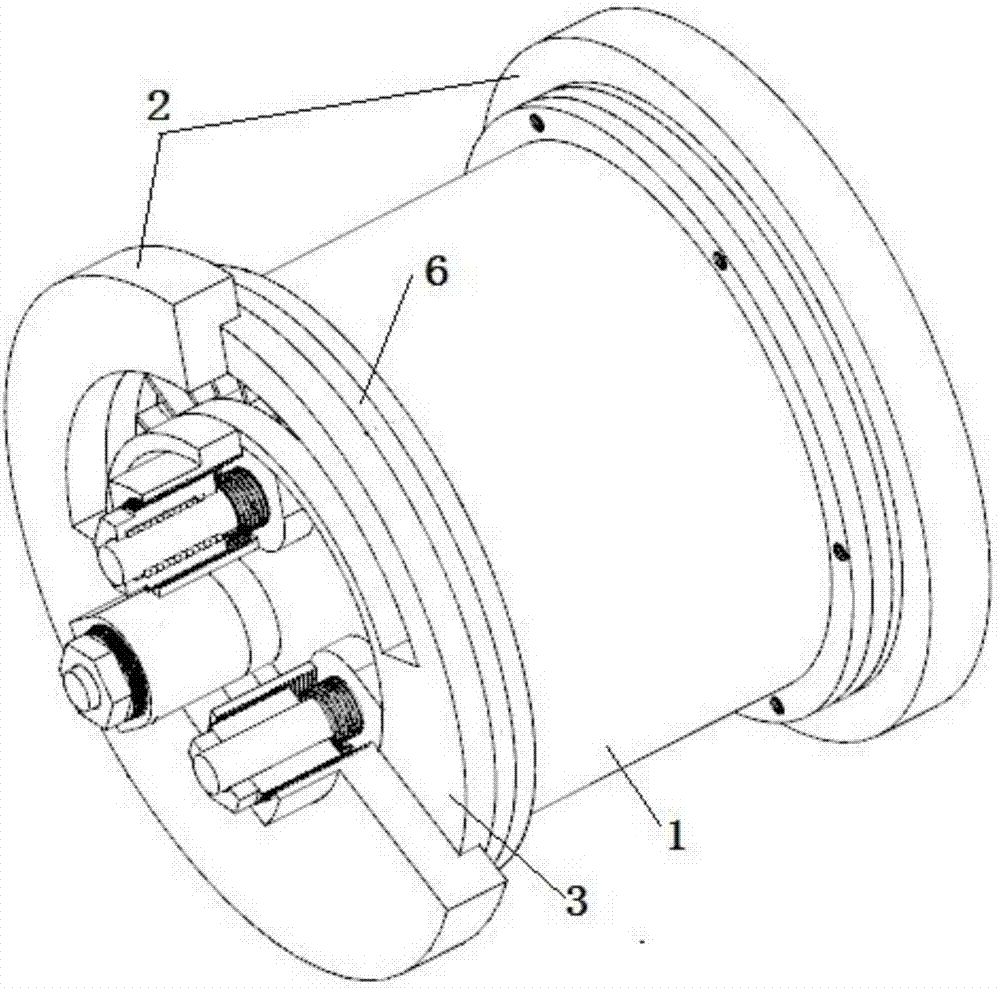

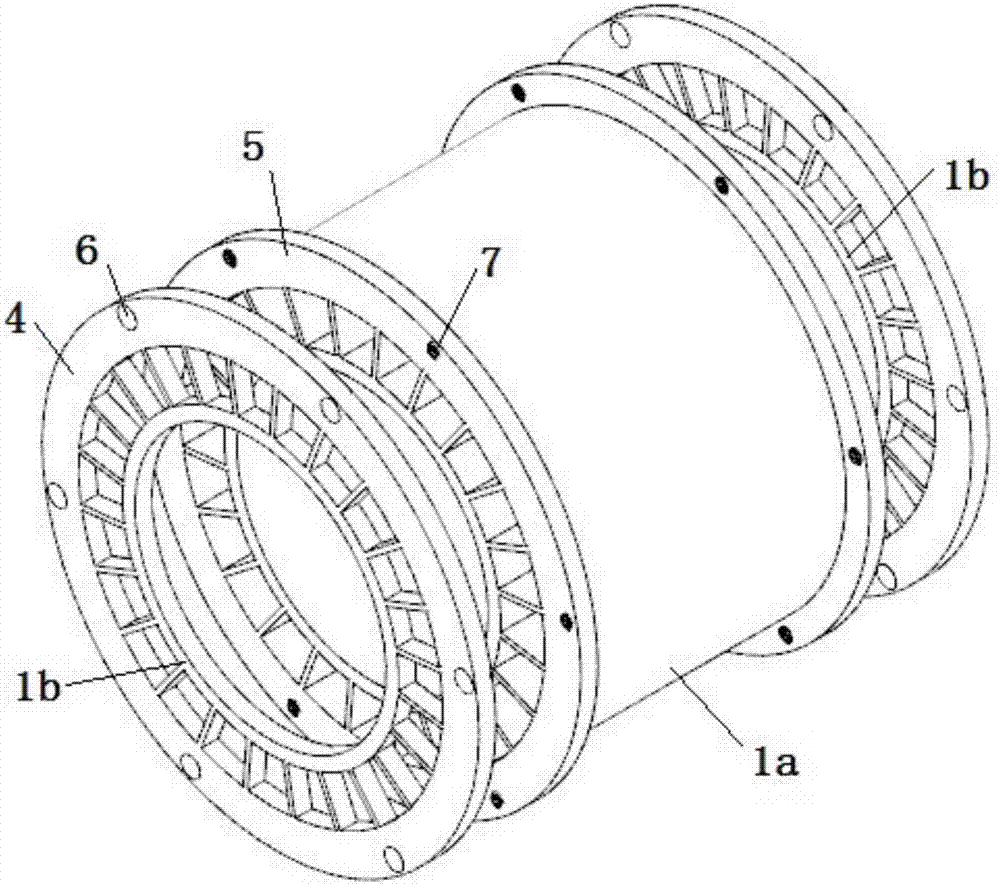

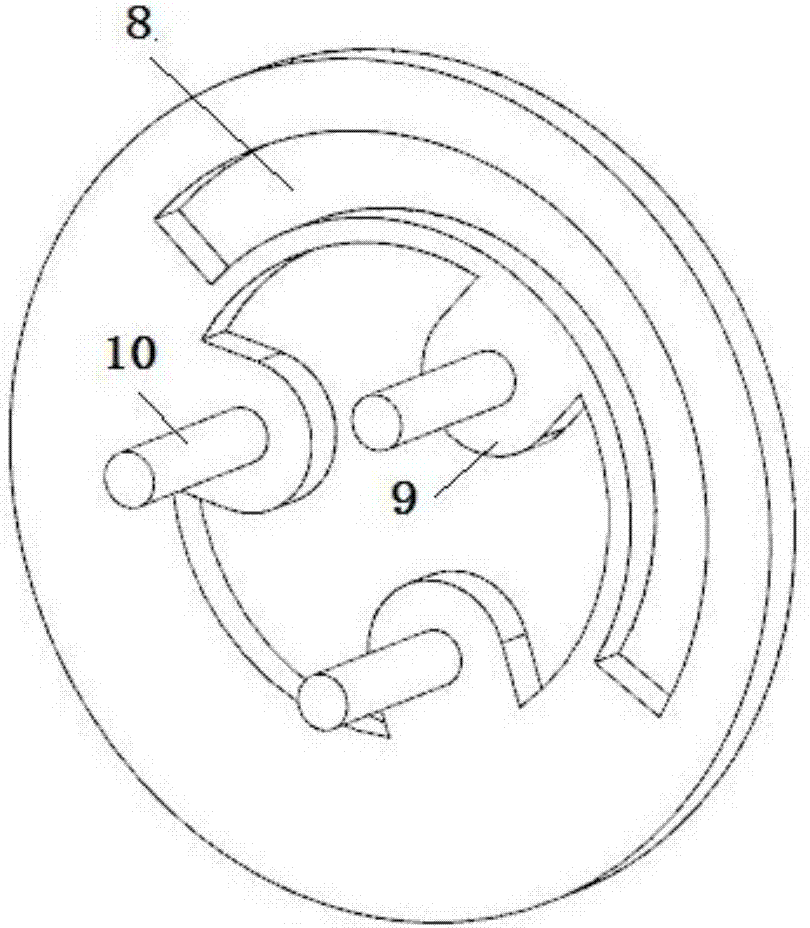

[0026] It mainly includes the wave rotor 1, the fixed end cover 2 and the movable end cover 3. The wave rotor 1 includes the wave rotor main body 1a and the friction plate 1b. The wave rotor main body 1a channel is arranged at both ends of the wave rotor main body connecting flange 5, the friction plate 1b The friction plate connecting flange 4 is arranged on the periphery, the threaded holes 7 are evenly arranged on the wave rotor main body connecting flange 5, and the counterbore 6 corresponding to the threaded holes 7 is evenly arranged on the friction plate flange 4. The rotor body 1a and the friction plate 1b are connected to form an integral structure of the wave rotor 1, and the he...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com