Rail walking type suspended overhead sprinkling irrigation system

A track-type and track-based technology, which is applied in the fields of climate change adaptation, horticulture, botanical equipment and methods, etc., can solve the problems of poor irrigation efficiency, time-consuming and labor-intensive work, overlap of corner radiation work surfaces, etc., and achieve high device integration and improved Sprinkler irrigation efficiency, the effect of expanding the working area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

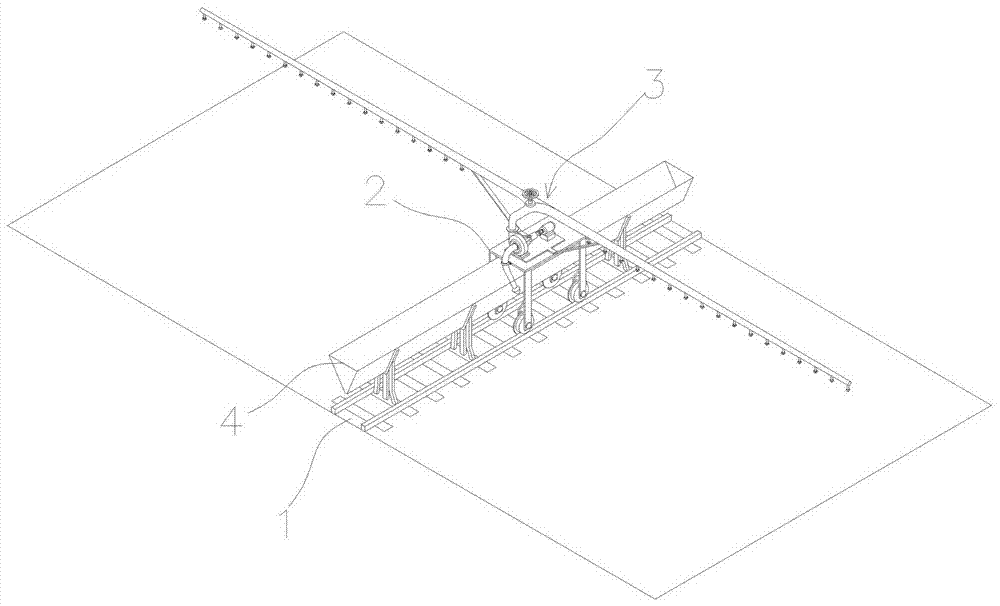

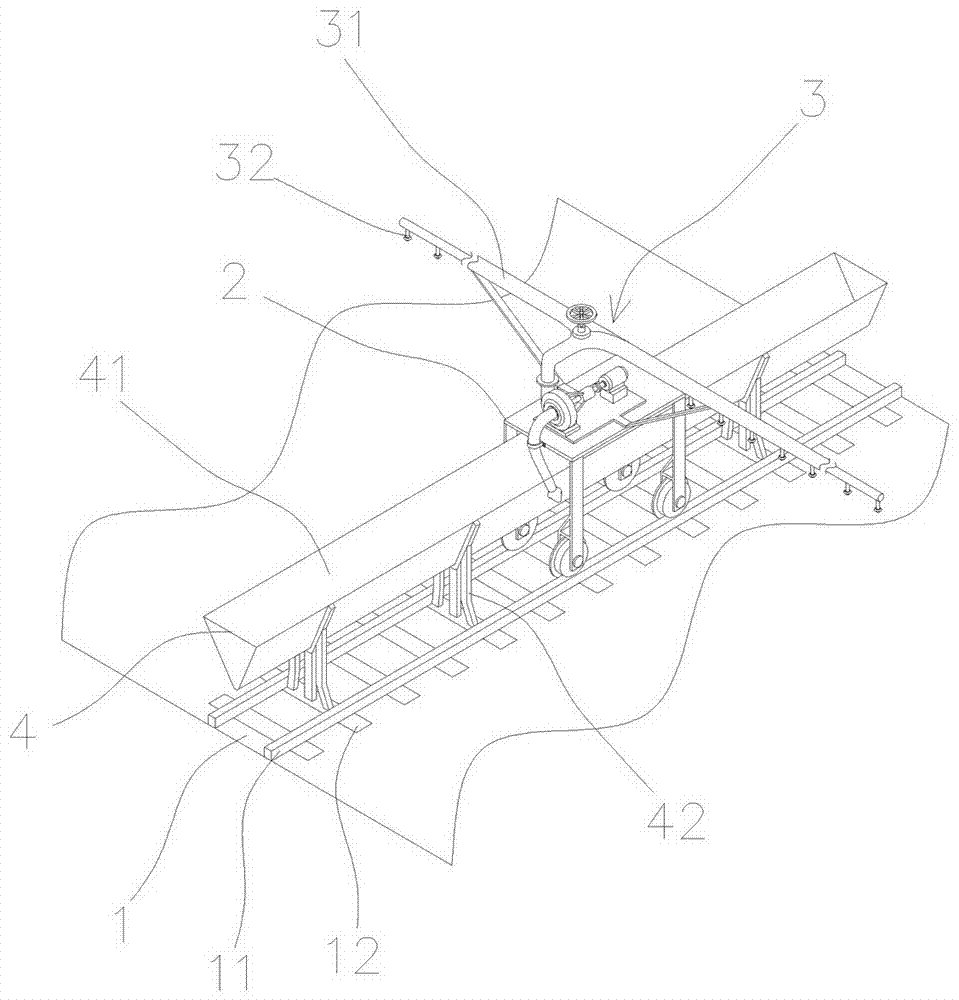

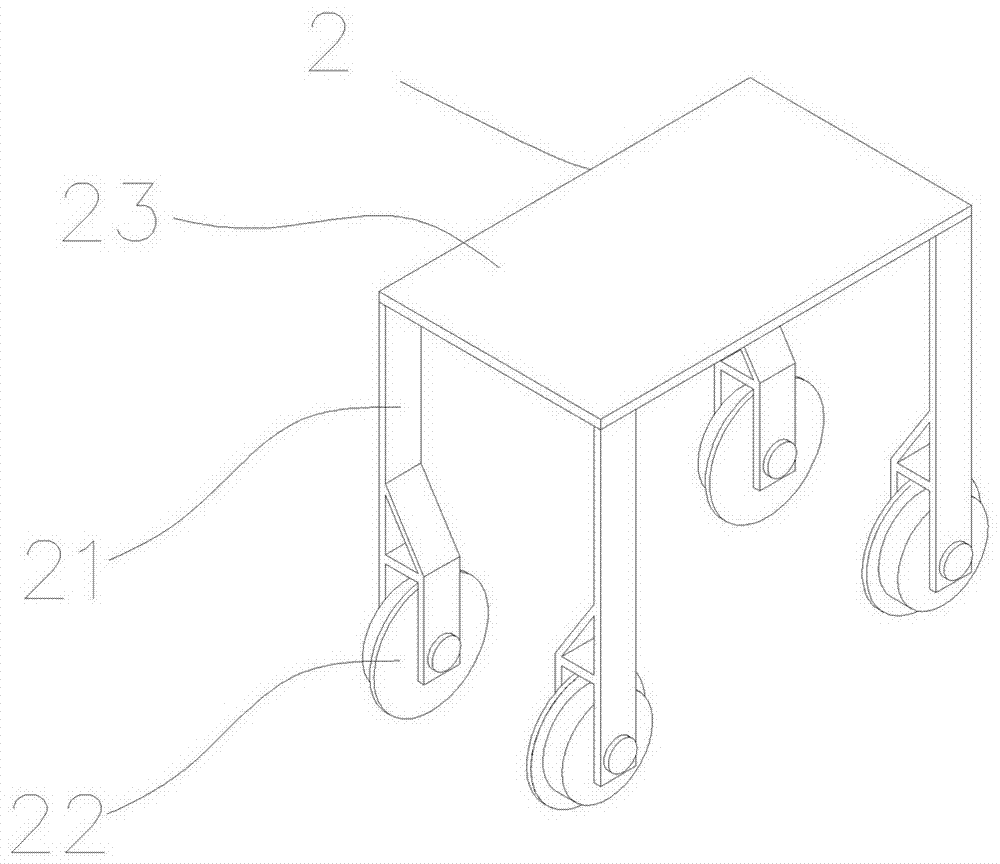

[0046] Such as figure 1 , 2 As shown, the suspended overhead sprinkler irrigation system for rail 1 type walking described in this embodiment includes a rail 1, a work vehicle 2, and a water tank 4. The rail 1 includes a guide rail 11 and a bearing part 12. The bearing part 12 is laid on the ground, and the bearing part 12 can be laid in the form of multiple sleepers arranged at intervals or continuous splicing of multiple sheets. The bearing part 12 and guide rail 11 can be fixed on the ground to make it an infrastructure for farmland construction, or it can be quickly dismantled and quickly installed to facilitate transfer , wheel types, etc.; the used sleepers of the bearing part 12 can adopt wooden sleepers, reinforced concrete sleepers, steel sleepers or composite material sleepers, or lay track beds on the ground to strengthen the operational stability of the equipment. The guide rail 11 of the track 1 is made of I-beam or angle steel or a composite material, the guide ...

Embodiment 2

[0054] Based on the above embodiments, the height of the main pipeline 31 in this embodiment can be adjusted. The height of the main pipeline 31 is adjustable, and its purpose is to make the height of the main pipeline 31 working surface, that is, the nozzle 32 adjustable, so that the water is sprayed on different heights according to the requirements of the crops, so that the crops can be sprayed on different heights in the process of seedlings, adult plants, earing, and knotting. In stages such as ears, it can be sprayed on specific parts. The main pipeline 31 is provided with a lifting device 5, which can adjust the height of the main pipeline and / or the spray head. The lifting device 5 used for the adjustment of the main pipeline 31 includes but is not limited to two methods: the lifting adjustment of the pipe frame 34 and the telescopic adjustment of the water spray pipe 33, or the joint action of the two methods to achieve the height of the working surface of the main pi...

Embodiment 3

[0058] On the basis of the above embodiments, the main pipeline 31 in this embodiment is provided with lifting devices 6 , the number of which is at least one set. The hoisting device 6 mainly plays a role in lifting the main pipeline 31, especially the middle part and the end of the main pipeline 31; after the main pipeline 31 is filled with water, the middle part and the end are prone to inclination and bending. more serious. The above-mentioned situation can be avoided by lifting the main pipeline 31 by the hoisting device 6 .

[0059] Such as Figure 7 , 8 As shown, the lifting device 6 includes a column 61, a backguy 62, and a lifting rod 63. There are two uprights 61, which are fixed at both ends of the ground in the direction of the track 1. 63 is articulated with the main pipe 31; the lifting rod 63 includes a rod body 64 and a wire pulley 65, and the wire pulley 65 is located at the upper end of the rod body 64, and its wheel surface has a groove, and rides on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com