Three-dimensional positioning device for underwater high-pressure water dirt removing nozzle

A three-dimensional positioning, high-pressure water technology, applied in measuring devices, cleaning methods and utensils, cleaning methods using liquids, etc., can solve the problems of high labor intensity, low operation efficiency, poor operation reliability, etc. The effect of improving the accuracy of work

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The technical solution of the present invention will be further described in conjunction with the accompanying drawings.

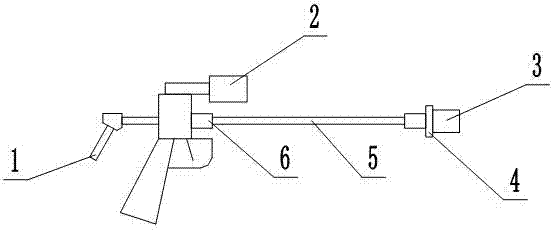

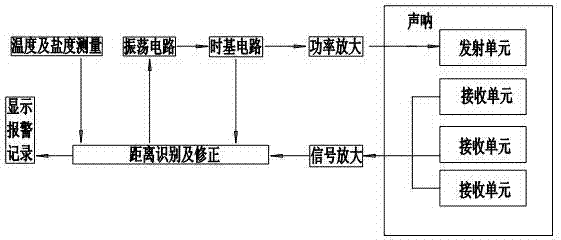

[0017] A three-dimensional positioning device for an underwater high-pressure water decontamination nozzle, comprising a variable-length water nozzle 5, a high-pressure water nozzle 3 fixed to the front end of the barrel of the variable-length water nozzle 5 through a nozzle quick lock device 4, and a high-pressure water inlet connected to the rear end of the barrel. Water pipe 1, the gun barrel is fixed on the gun body by the water gun quick lock device 6, and also includes an underwater sonar 3D positioning unit 2 arranged on the gun body, and the underwater sonar 3D positioning unit 2 includes a sonar signal generator connected by a circuit , a power amplifier, a sonar with a transmitting unit and three receiving units equidistantly distributed along the circumference, a signal amplifier, a distance identification and correction module, a temperat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com