Multifunctional spray-head for 3D printer

A 3D printer and multi-functional technology, applied in the direction of 3D object support structure, processing and manufacturing, manufacturing tools, etc., can solve the problems of large size of nozzle, instability of the whole machine, and no filaments from the nozzle, so as to achieve strong material adaptability and solve the problem of The effect of printing failure and strong wire feeding force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] In order to further understand the present invention, the preferred embodiments of the present invention are described below in conjunction with examples, but it should be understood that these descriptions are only to further illustrate the features and advantages of the present invention, rather than limiting the claims of the present invention.

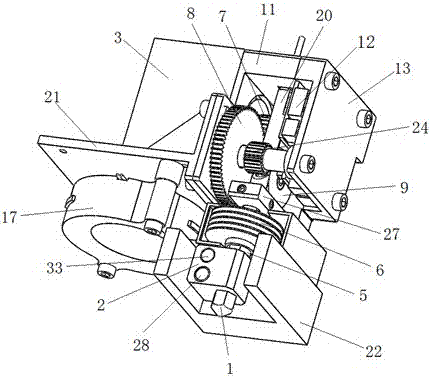

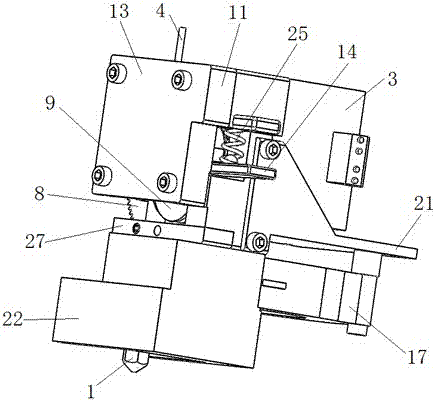

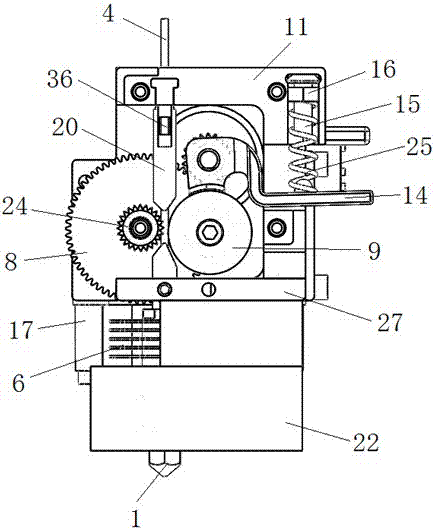

[0024] Such as Figure 1-4 It is a schematic structural diagram of a preferred embodiment of the multifunctional nozzle for 3D printers of the present invention. As shown in the figure, it includes motor 3, small spur gear 7, large spur gear 8, extruder gear 24, cage 11, circuit board 12, end cover 13, runner 9, runner pressure rod 14, compression spring 25. Printing wire conduit 20, pressure measuring block 27, throat pipe 5, heat sink 6, heating block 2, nozzle 1, fan 17, air duct 22, connecting frame 21 and other parts, cage 11, end cover 13 and connecting frame 21 forms a bracket, and the circuit board 12 is installed i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com