Preparation method of monodispersed hexanitrohexaazaisowurtzitane micron hollow spheres

A technology of hexanitrohexaazane and isowurtzitane is applied in the field of preparation of hexanitrohexaazaisowurtzitane micron hollow spheres, and can solve the problems of poor dispersibility, complicated process, hexanitrohexaazaisowurtzitane micron There are few problems in the preparation of hollow spherical explosives, such as narrow particle size distribution, simple process flow, and mild experimental conditions.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

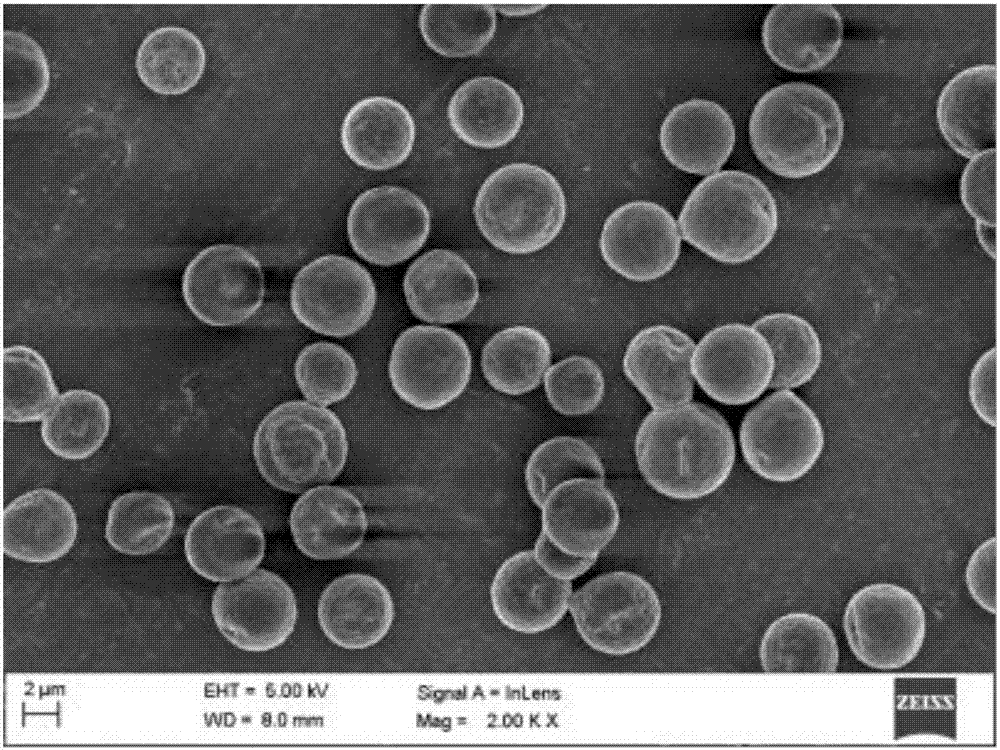

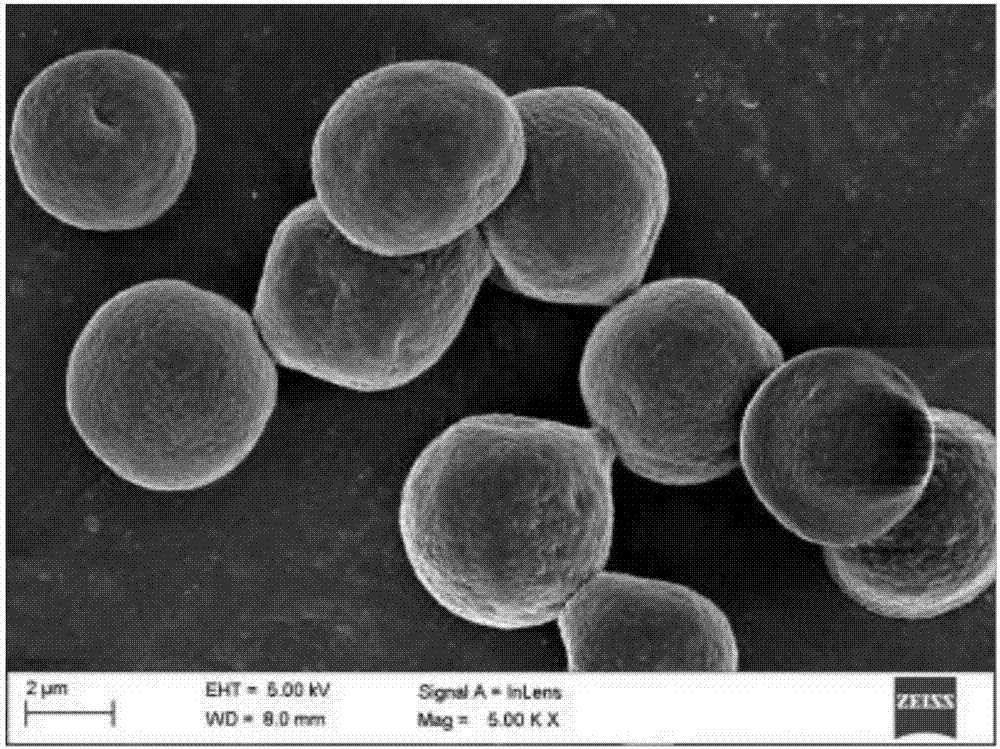

Embodiment 1

[0024] Weigh 0.5 g of hexanitrohexaazaisowurtzitane at room temperature, weigh 9 g of butyl acetate, and stir at 500 rpm to completely dissolve into a clear solution. Quickly put the resulting solution into a 5mL plastic syringe, replace the syringe with a 27G flat-top metal needle, and then install the syringe on the pusher pump in the electrostatic spray device with an ambient temperature of 30℃, and set the flow rate of the pusher pump. For 0.05mm / s, connect the positive high voltage to the metal flat pin. Fix the aluminum foil as the collector on an insulating plate and connect it to the negative high voltage power supply. Adjust the distance between the flat top needle and the collector to 20cm. Turn on the switch of the propulsion pump, first adjust the negative voltage to -10kV, and then adjust the positive voltage to 6kV. At this time, a Taylor cone appears on the flat top needle. After a period of stability, turn off the instrument to obtain monodisperse hexanitrohex...

Embodiment 2

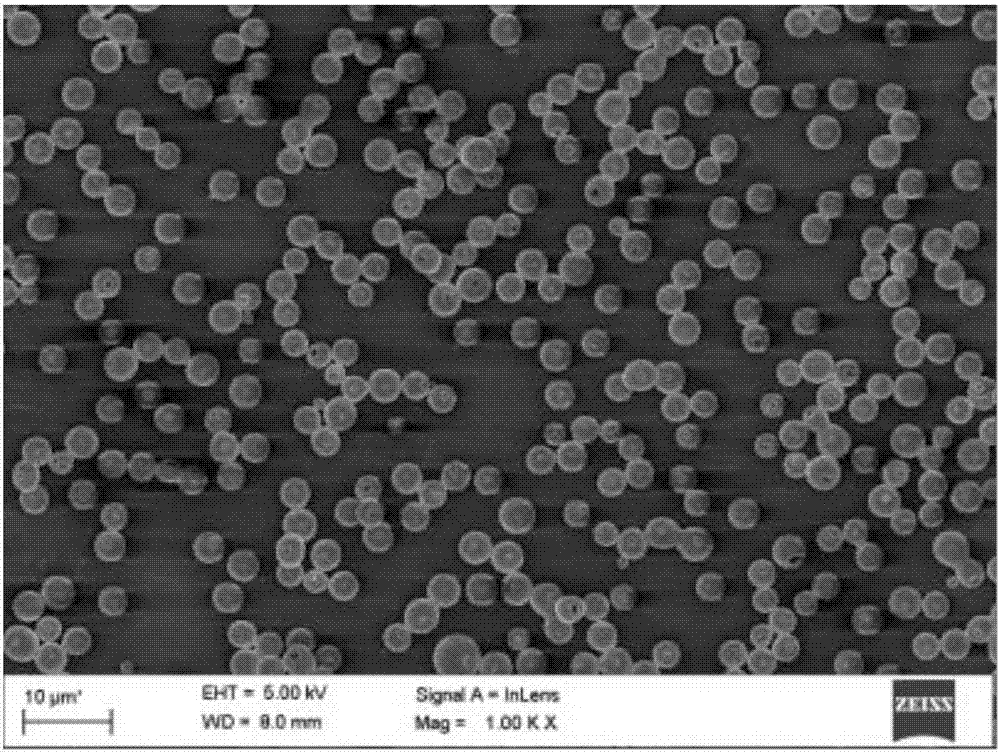

[0026] Weigh 10 g of hexanitrohexaazaisowurtzitane at room temperature, measure 20 mL of acetone, and stir at 300 rpm to completely dissolve into a clear solution. Quickly put the resulting solution into a 5mL plastic syringe, replace the syringe with a 19G flat-top metal needle, and then install the syringe on the pusher pump in the electrostatic spray device with an ambient temperature of 20℃, and set the flow rate of the pusher pump. 0.2mm / s, connect the positive high voltage to the flat metal needle. Fix the aluminum foil as the collector on an insulating plate and connect it to the negative high voltage power supply. Adjust the distance between the flat top needle and the collector to 10cm. Turn on the switch of the propulsion pump, first adjust the negative voltage to -7kV, and then adjust the positive voltage to 6kV. At this time, a Taylor cone appears on the flat tip. After a period of stability, turn off the instrument to obtain monodisperse hexanitrohexaazaisowurtzi...

Embodiment 3

[0028] Weigh 2 g of hexanitrohexaazaisowurtzitane at room temperature, measure 10 mL of dimethylformamide, and stir at 700 rpm to completely dissolve it into a clear solution. Quickly put the resulting solution into a 5mL plastic syringe, replace the syringe with a 23G flat-topped metal needle, then install the syringe on the pusher pump in the electrostatic spray device with an ambient temperature of 35℃, and set the flow rate of the pusher pump. 0.075mm / s, connect the positive high voltage to the metal flat pin. Fix the aluminum foil as the collector on an insulating plate and connect it to the negative high voltage power supply. Adjust the distance between the flat top needle and the collector to 25cm. Turn on the switch of the propulsion pump, first adjust the negative voltage to -10kV, and then adjust the positive voltage to 8kV. At this time, a Taylor cone appears on the flat top needle. After a period of stability, turn off the instrument to obtain monodisperse hexanit...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

| Size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com