A thermal energy circulation Chinese style frying furnace device

A Chinese-style, thermal energy technology, applied in the direction of household heating, heating fuel, household stove/stove, etc., can solve the problems of waste gas emission pollution, etc., and achieve the effects of solving emission pollution, safe and stable combustion, and improving heat conversion rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

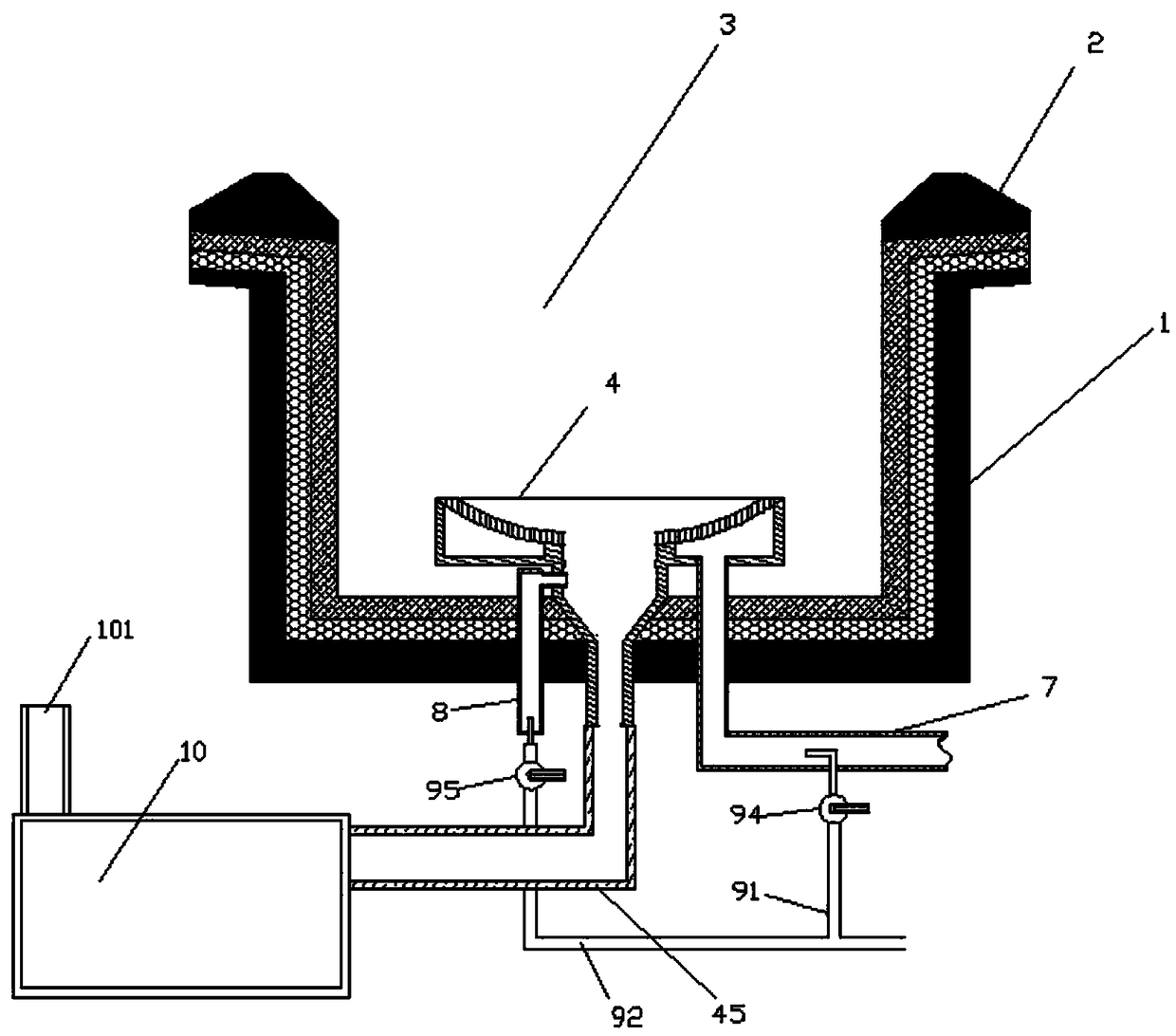

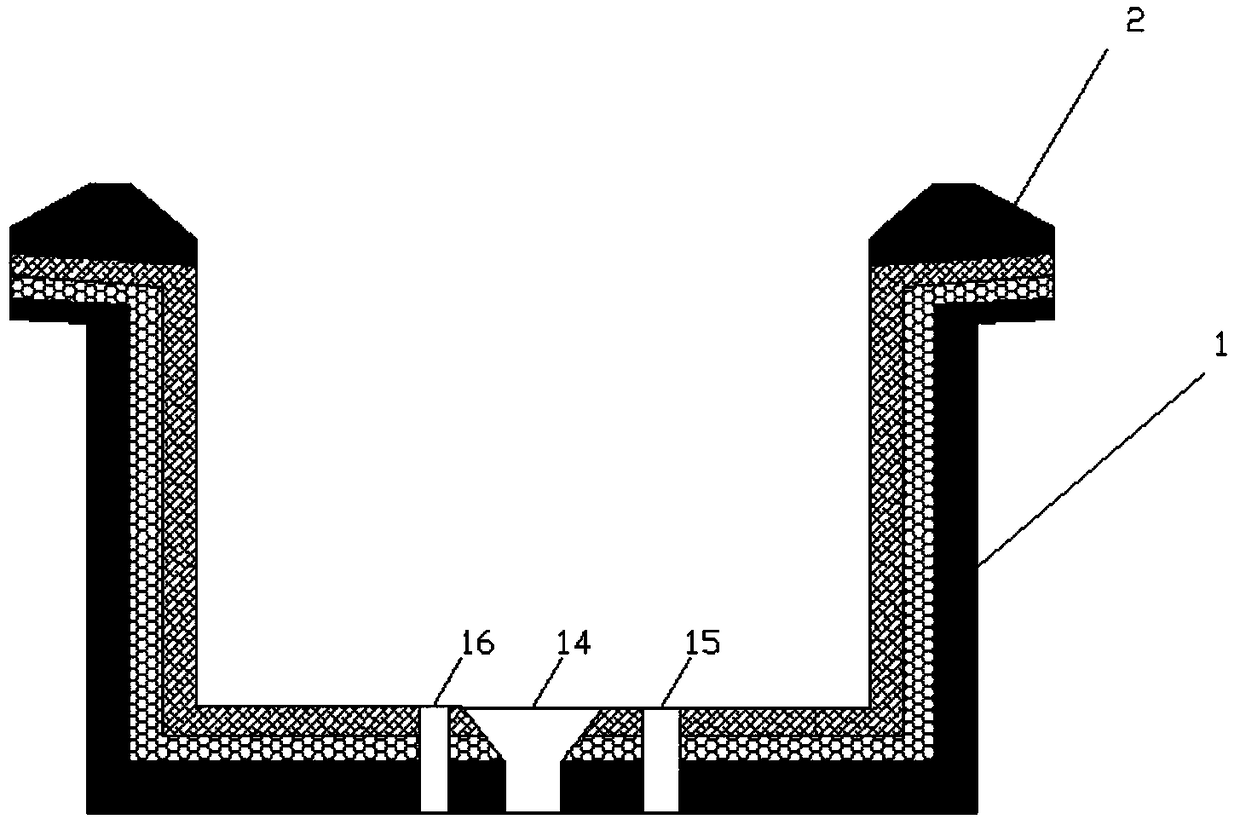

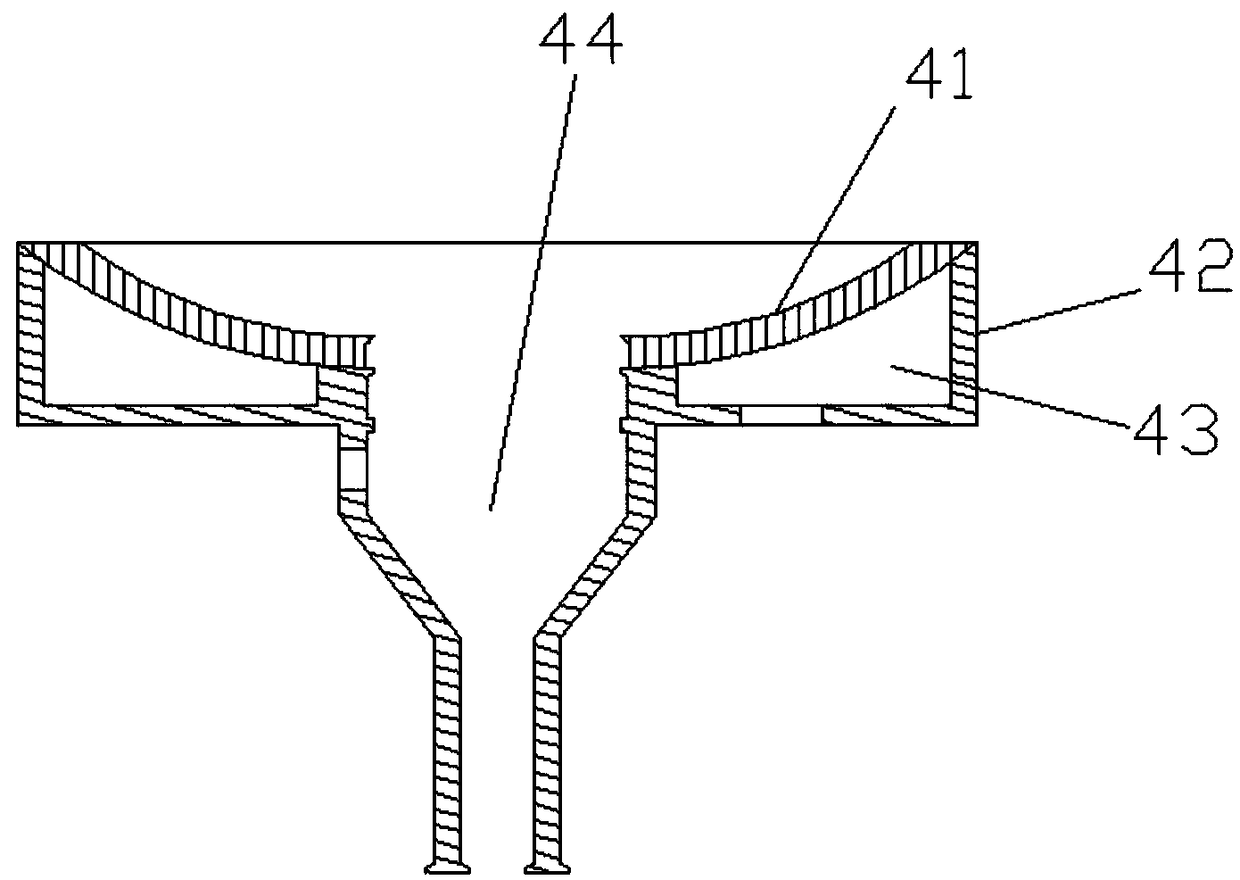

[0041] see Figure 1~3 , the present invention provides a technical solution:

[0042] A thermal energy circulation Chinese style frying furnace device, comprising a burner 4, a furnace 3, a furnace shell 1 and a wok support 2, the burner 4 includes a combustion plate 41, a burner support 42 and a gas mixing chamber 43, the combustion plate 41 is located on the burner bracket 42, the middle part of the burner 4 is provided with a waste gas outlet 44, the top of the furnace shell 1 is provided with a frying pan support 2, and the bottom of the furnace shell 1 is provided with a first installation hole 14 in the center, so The furnace head 4 is located in the furnace 3, the bottom of the furnace head 4 is located in the first installation hole 14, the bottom of the furnace shell 1 is also provided with a second installation hole 15 and a third installation hole 16, and the second installation hole 15 is provided with an air-air mixing pipe 7, which is connected to the gas mixin...

Embodiment 2

[0044] see Figure 3-5 , the present invention provides a technical solution:

[0045]A thermal energy circulation Chinese style frying furnace device, comprising a burner 4, a furnace 3, a furnace shell 1 and a wok support 2, the burner 4 includes a combustion plate 41, a burner support 42 and a gas mixing chamber 43, the combustion plate 41 is located on the burner bracket 42, the middle part of the burner 4 is provided with a waste gas outlet 44, the top of the furnace shell 1 is provided with a frying pan support 2, and the bottom of the furnace shell 1 is provided with a first installation hole 14 in the center, so The furnace head 4 is located in the furnace 3, the bottom of the furnace head 4 is located in the first installation hole 14, the bottom of the furnace shell 1 is also provided with a second installation hole 15 and a third installation hole 16, and the second installation hole 15 is provided with an air-air mixing pipe 7, which is connected to the gas mixing...

Embodiment 3

[0047] see Figure 6 ~ Figure 8 , the present invention provides a technical solution:

[0048] A thermal energy circulation Chinese style frying furnace device, comprising a burner 4, a furnace 3, a furnace shell 1 and a wok support 2, the burner 4 includes a combustion plate 41, a burner support 42 and a gas mixing chamber 43, the combustion plate 41 is located on the burner bracket 42, the middle part of the burner 4 is provided with a waste gas outlet 44, the top of the furnace shell 1 is provided with a frying pan support 2, and the bottom of the furnace shell 1 is provided with a first installation hole 14 in the center, so The furnace head 4 is located in the furnace 3, the bottom of the furnace head 4 is located in the first installation hole 14, the bottom of the furnace shell 1 is also provided with a second installation hole 15 and a third installation hole 16, and the second installation hole 15 is provided with an air-air mixing pipe 7, which is connected to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com