Circular cutter processing cutter-axis vector smoothing method based on AB type five-axis CNC machine tool

A technology of tool axis vector and CNC machine tools, which is applied to five-axis CNC machine tool axis vector smoothing. Based on the field of tool axis vector smoothing of AB five-axis CNC machine tool ring tool processing, it can solve the sudden change and large fluctuation of the tool axis vector on curved surfaces. and other problems, to achieve the effect of smooth and smooth movement, avoid sudden changes, and avoid smoothness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

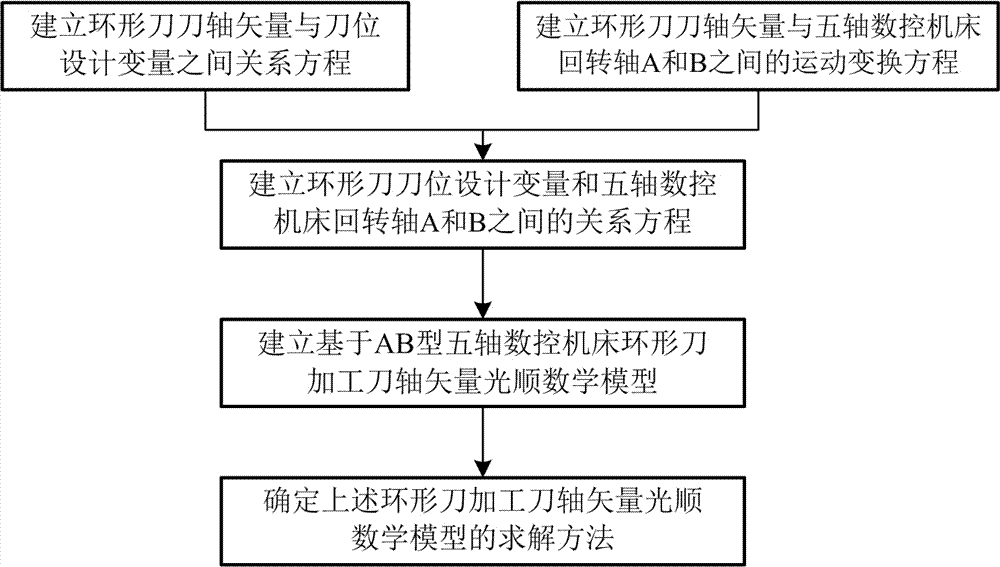

[0043] According to the present invention, a method based on AB type five-axis CNC machine tool machining tool axis vector smoothing method, its basic process is as follows figure 1 As shown, preferred specific implementation methods include:

[0044] Step A, establishing the relational equation between the tool axis vector of the annular cutter and the design variable of the cutter position. Described step A specifically is:

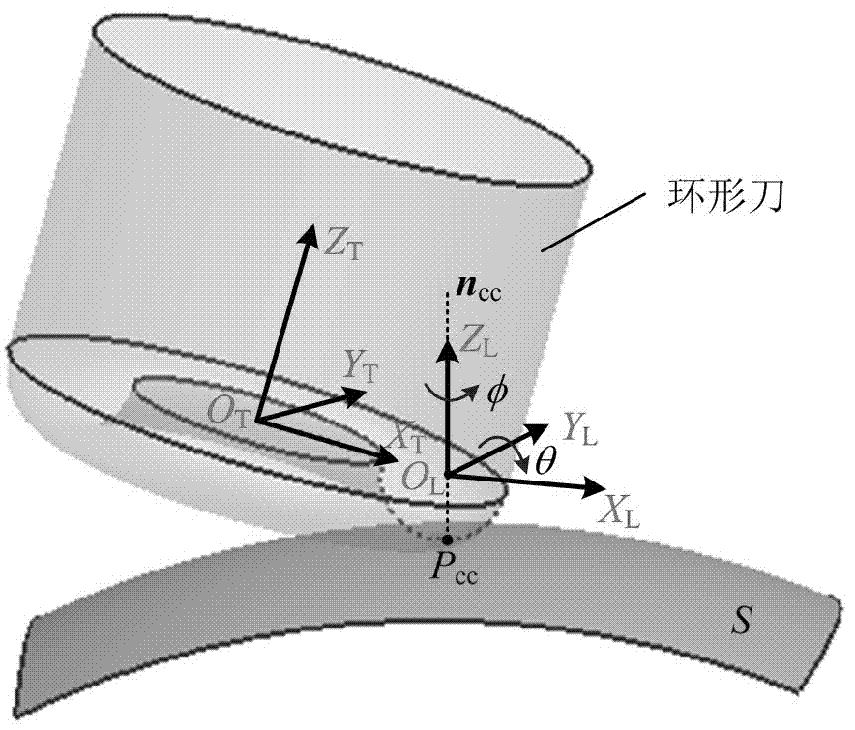

[0045] (1) The relationship equation between the circular tool axis vector and the tool position design variables in the local coordinate system

[0046] Such as figure 1 As shown, assume that the circular cutter processes the surface S of the workpiece, r(u,v), P cc (u cc ,v cc ) is any point on the surface, n cc is the unit normal vector of the point. Let r be the truncated circle radius of the ring knife, O L is the origin of the local coordinate system, then in point O L and P cc Corresponding radial vector. At the same time, with poi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com