Magnetic suspension gravity compensator

A technology of gravity compensation and magnetic levitation, which is applied in the field of magnetic levitation, can solve problems such as complex structure of the device, and achieve the effects of small force fluctuation, low loss, and high force density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

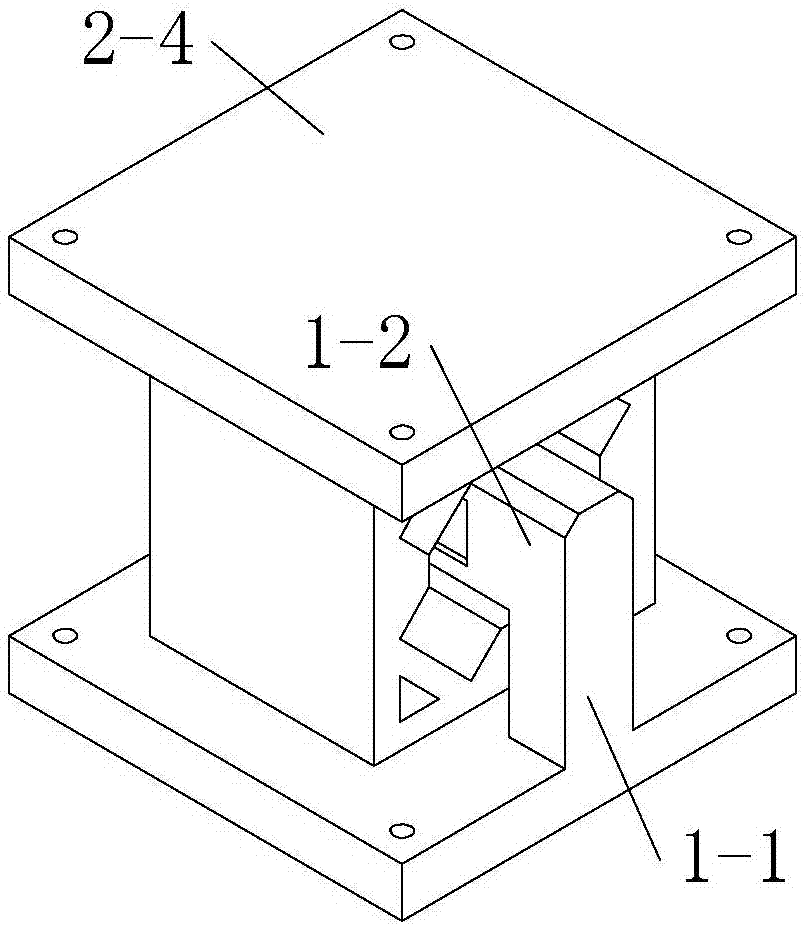

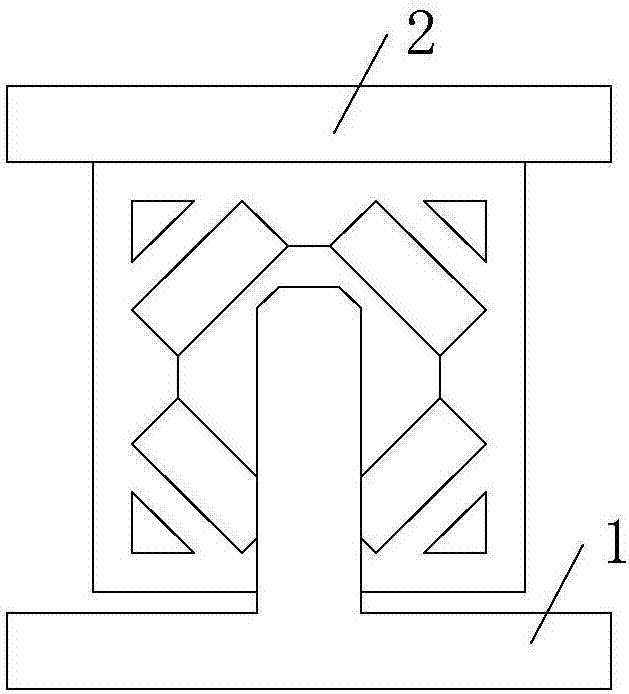

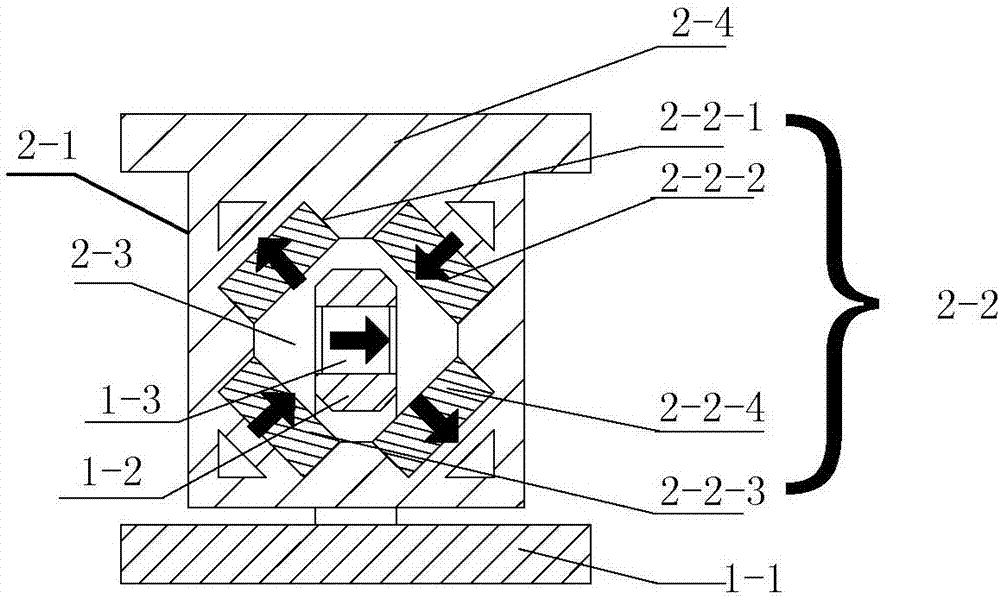

[0053] Specific implementation mode one: see Figure 1 to Figure 3 ,and Figure 23 and Figure 24 Describe this embodiment, the magnetic levitation gravity compensator described in this embodiment, it comprises a stator 1 and a mover 2;

[0054]Stator 1 includes stator frame 1-1, stator beam 1-2 and stator permanent magnet 1-3; the number of stator permanent magnet 1-3 is 1 or 2, when the number of stator permanent magnet 1-3 is 1, The stator permanent magnet 1-3 is embedded in the stator beam 1-2, and the two are coaxial. When the number of the stator permanent magnet 1-3 is 2, two stator permanent magnets 1-3 are respectively embedded in the stator beam 1. The upper, lower or left and right surfaces of -2; the stator beam 1-2 is fixed on the stator frame 1-1;

[0055] The mover 2 includes a mover frame 2-1 and a mover base 2-4, the mover frame 2-1 is fixed on the lower surface of the mover base 2-4, and a mover permanent magnet is arranged inside the mover frame 2-1 A di...

specific Embodiment approach 2

[0073] Specific implementation mode two: see Figure 1 to Figure 6 , Figure 23 and Figure 24 Describe this embodiment, the difference between this embodiment and the magnetic levitation gravity compensator described in Embodiment 1 is that the stator 1 also includes two sets of stator coils 1-4; the two sets of stator coils 1-4 are rectangular structures, And it is symmetrically embedded in the left and right surfaces of the stator beam 1-2, and runs through the cavity 2-3.

[0074] For details, see Figure 6 , when the number of stator permanent magnets 1-3 is 1, the magnetic levitation gravity compensator utilizes the interaction force between the stator permanent magnets 1-3 and the mover permanent magnet rhombic array and the interaction between the stator coils 1-4 and the mover The interaction force between the magnetic fields generated by the rhombic array of sub-permanent magnets realizes magnetic levitation and compensation for gravity;

[0075] Stator permanent...

specific Embodiment approach 3

[0088] Specific implementation mode three: see Figure 1 to Figure 7 , Figure 23 and Figure 24 Describe this embodiment. The difference between this embodiment and the magnetic levitation gravity compensator described in Embodiment 1 or 2 is that it also includes N stators 1 and N movers 2; N+1 movers 2 move along the Y axis It is arranged in series in the direction, and a stator beam 1-2 is correspondingly provided in the cavity 2-3 of each mover 2, N+1 mover bases 2-4 are integrated, and N+1 stator frames 1- The base of 1 is one piece, and N is an integer greater than or equal to 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com