Microphone structure and manufacturing method thereof

A manufacturing method and microphone technology, which is applied in the direction of electrostatic transducer microphones, sensors, electrical components, etc., can solve the problems that the performance of MEMS microphones needs to be improved, and achieve the effect of increasing the amount of change and improving sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] It can be seen from the background art that the performance of the microphone formed in the prior art needs to be optimized.

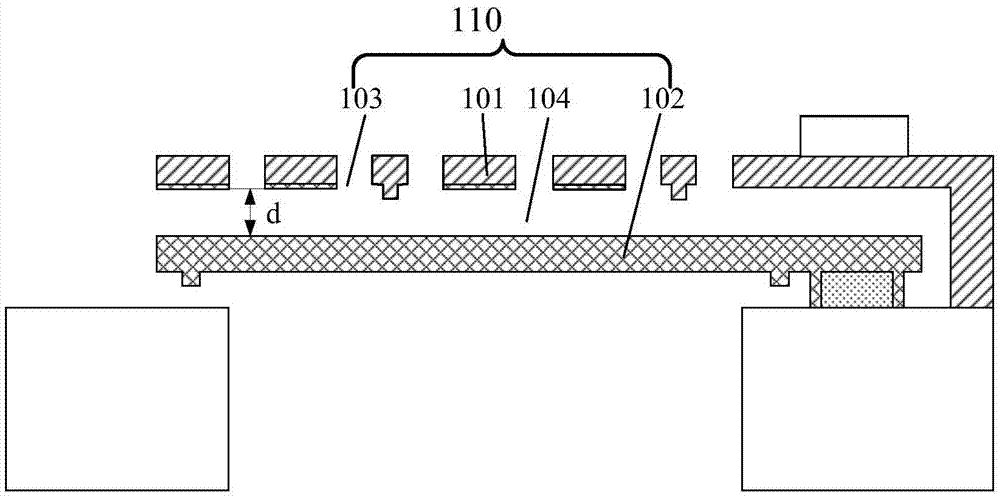

[0032] refer to figure 1 , figure 1 A schematic structural diagram of a microphone in the prior art is shown. The function of the microphone is realized by a capacitive structure 110 . The capacitive structure 110 mainly includes a diaphragm 102, a back plate 101, a cavity 104 between the diaphragm 102 and the back plate 101, and an acoustic hole 103 in the back plate 101. The diaphragm 102 and the back plate Plate 101 is used to form a capacitive plate. Air enters the cavity 104 through the sound hole 103 , and the air pressure generated by the sound causes the vibration of the diaphragm 102 , thereby changing the capacitance and finally causing a change in voltage. Among them, the parameters affecting the capacitance value mainly include the effective area of the capacitive plates (ie, the diaphragm 102 and the back plate 101 ) and the d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Height | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com