Automatic ring nesting and capping machine for edible fungus bags

An edible fungus and collar technology, which is applied in the fields of application, horticulture, and botanical equipment and methods to achieve the effect of reducing manpower, ensuring safety, and avoiding potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0054] In order to explain in detail the technical content, structural features, achieved goals and effects of the technical solution, the following will be described in detail in conjunction with specific embodiments and accompanying drawings.

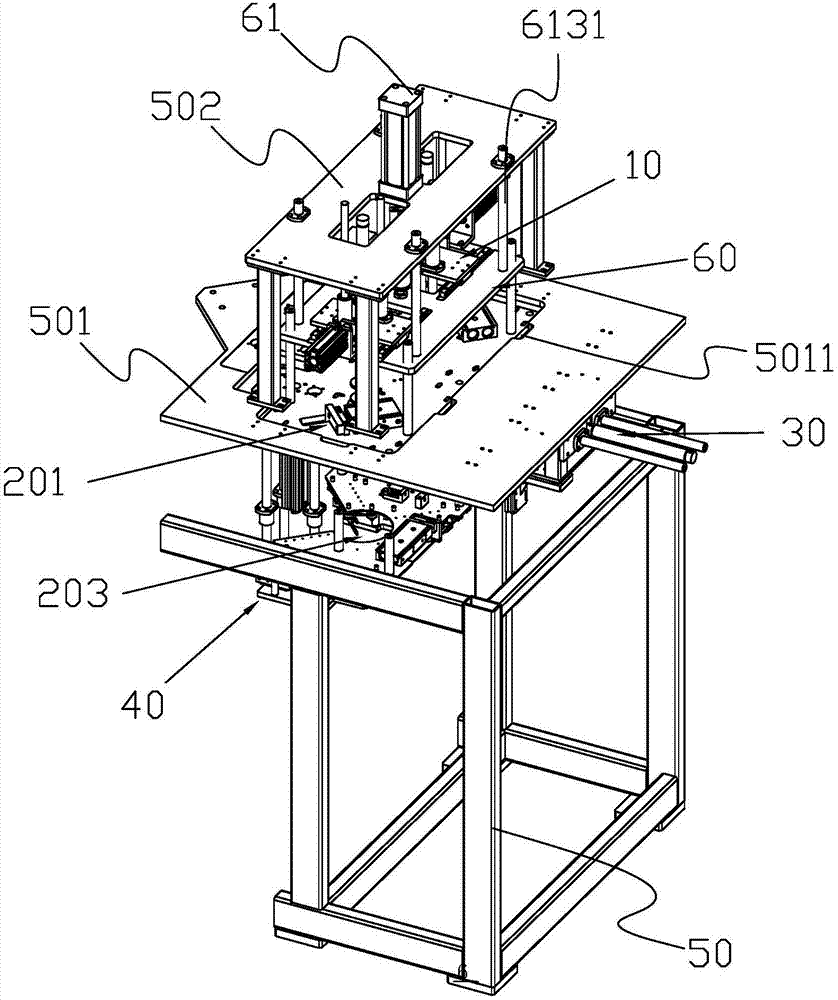

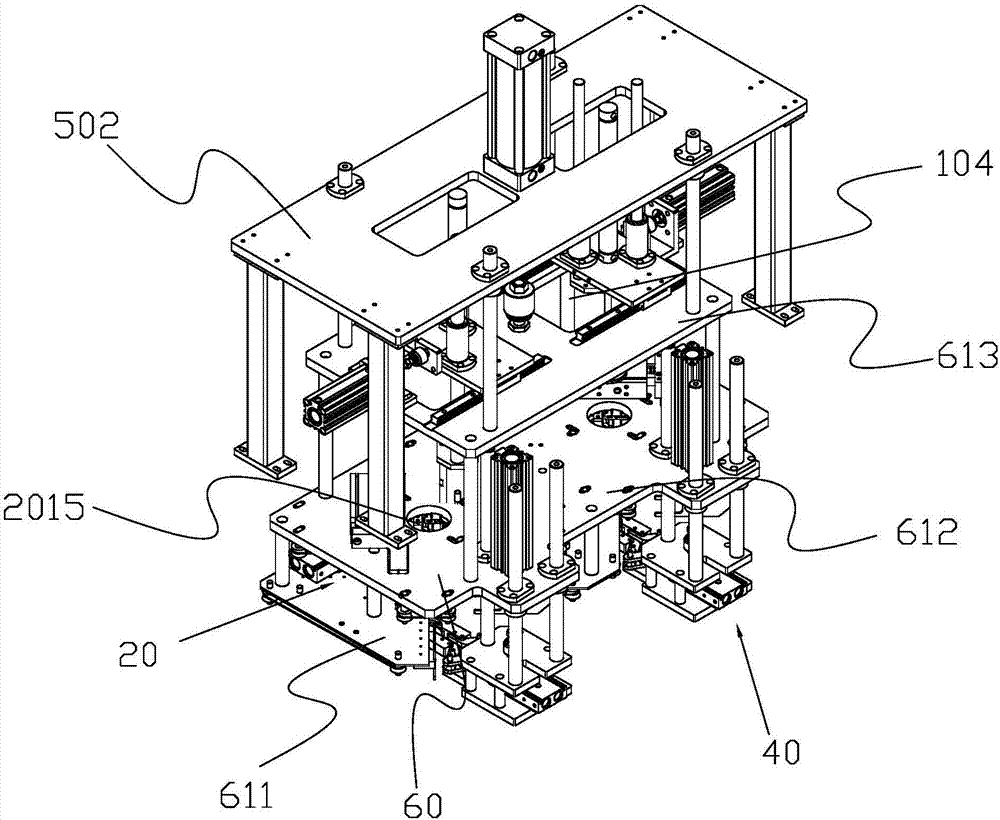

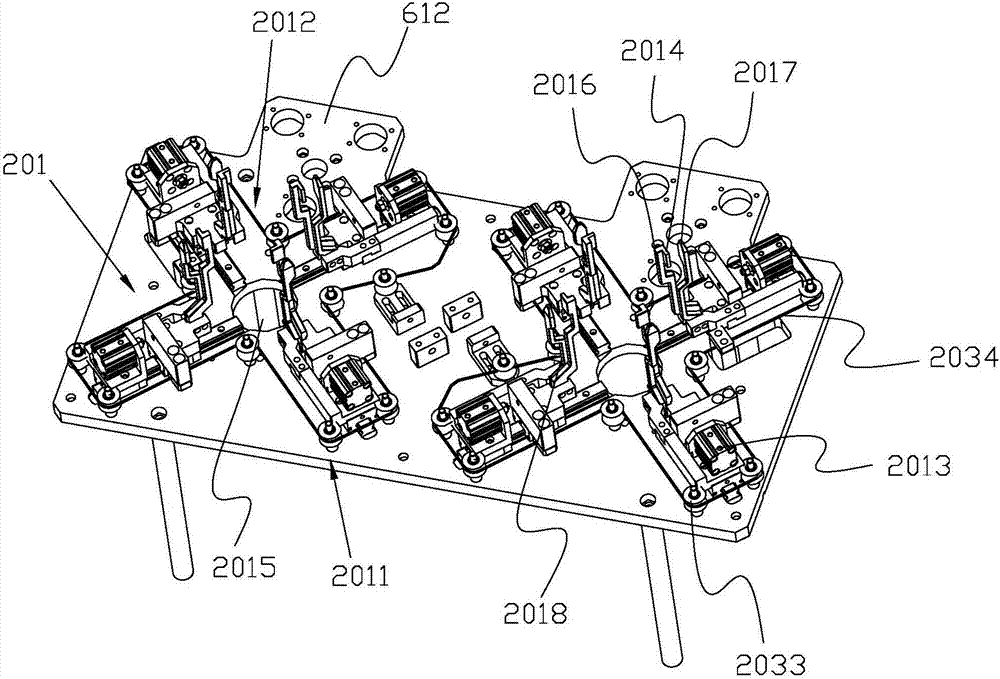

[0055] see Figure 1 to Figure 8 , the present embodiment is an automatic loop capping machine for edible mushroom bags, comprising a cap pressing mechanism 10, a necking mechanism 20, a loop mechanism 40, a main frame 50, a sub frame 60 and a sub frame power unit 61;

[0056]The sub-frame is arranged on the main frame, the power unit of the sub-frame is arranged on the upper end surface of the main frame, and the power output end of the power unit of the sub-frame is arranged on the sub-frame, and the sub-frame is used to drive the The mechanism on the sub-frame moves up and down in the station hole of the main frame;

[0057] The cap pressing mechanism, necking mechanism and collar mechanism are sequentially arranged on the sub-fra...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com