Fresh chestnut separator

A separator and chestnut technology, which is applied in the fields of shelling, pod removal, food science, etc., can solve the problems of low processing efficiency of separators and cannot protect the surface appearance quality of chestnut, and achieves the protection of surface appearance quality, continuous and high-efficiency separation and separation. inefficient effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

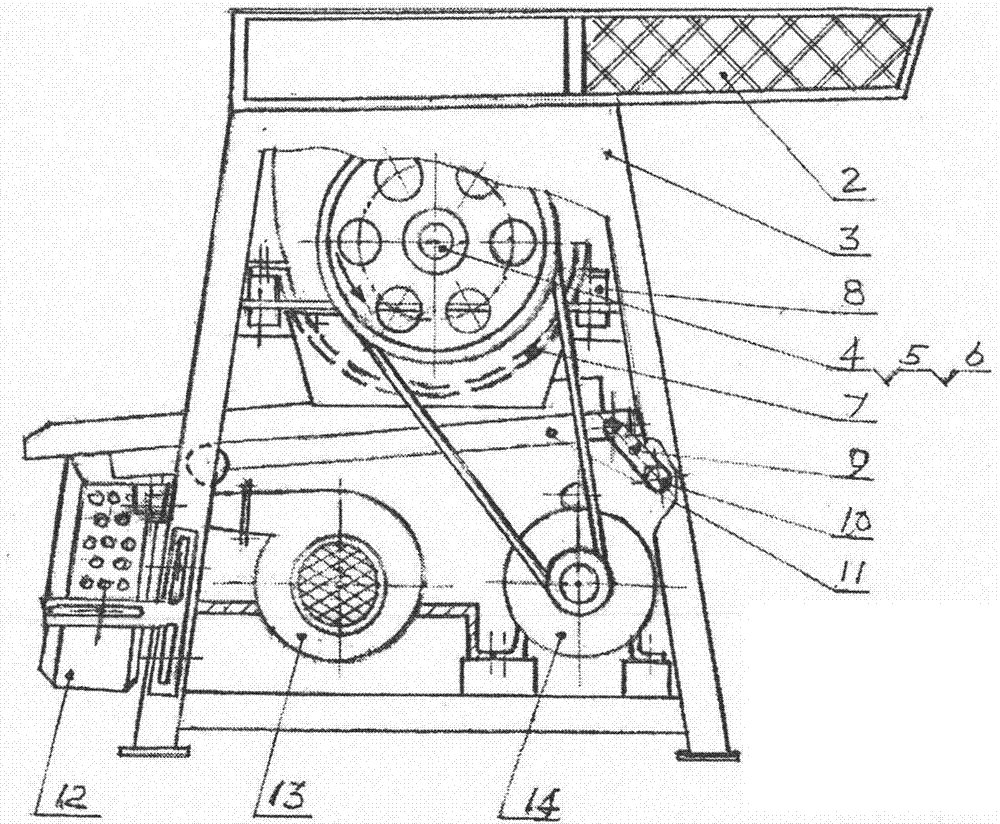

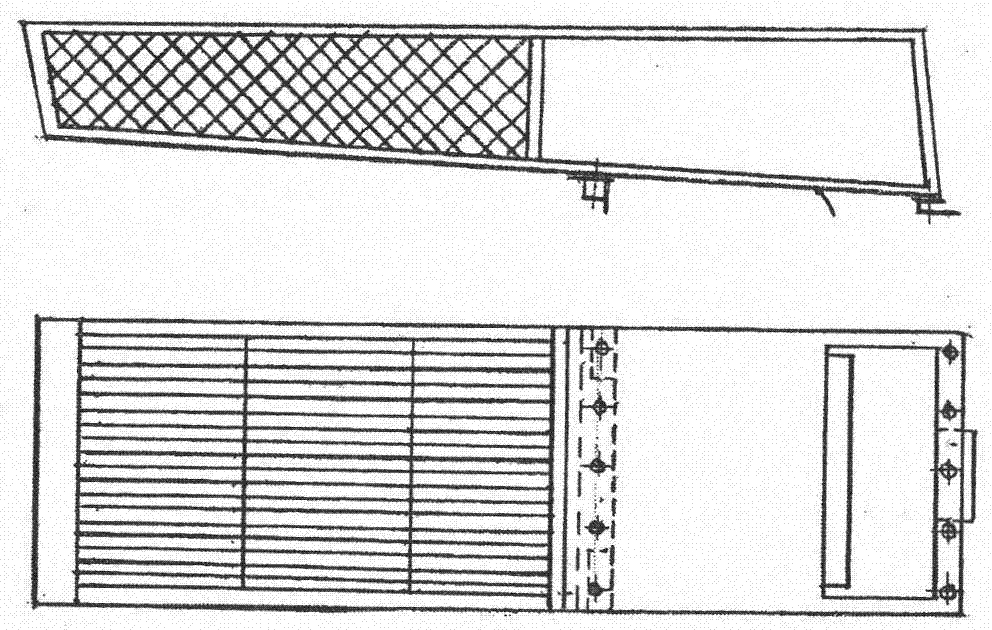

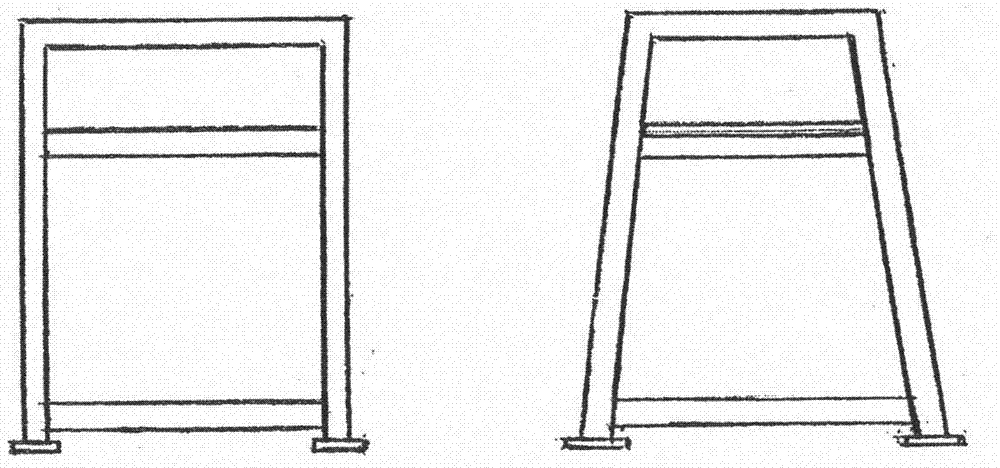

[0030] Refer to the accompanying drawings in the manual Figure 1-Figure 14 ,exist Figure 2-Figure 14 After the main components and all other manufactured and purchased parts are complete and qualified, the relevant technical personnel shall assemble the whole machine according to the following sequence; First First, the lower part of the complete machine is assembled, and the lower part includes: a motor (14) that can regulate and control the centrifugal fan (13). second , assemble the upper part of the spindle (7), assemble the spindle (7) with all the universal elastic floating support mechanisms (8) and assemble them on the two ends of the load-bearing beam on the left and right sides of the frame (3), and then put the crank The main shaft (4) and the drum (5) are combined to assemble the rotor assembly parts and the pulley at one end of the crank main shaft, and the rotor assembly parts are assembled on the specific positions set in the middle of the load-bearing beam...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com