Wrinkle-free edge covering structure and process for composite apron board of railway vehicle equipment compartment

A technology for rail vehicles and composite materials, which is applied in the field of wrinkle-free hemming structures and processes of composite material skirts in rail vehicle equipment cabins, and can solve the problems that cannot meet the needs of composite material equipment cabin skirts with beautiful appearance, simple repair and excellent durability. , Affect the appearance quality and service life of the apron, and the adjacent apron is not closely matched, so as to achieve the effect of good appearance quality, improve appearance quality, and avoid overlapping and overlapping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

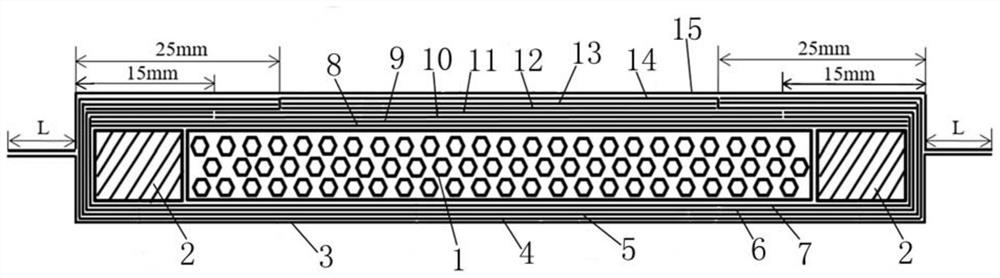

[0034] The invention provides a wrinkle-free edge-wrapping structure and process for the composite skirt board of a rail vehicle equipment compartment. Prepreg reinforcement layer 2, honeycomb sandwich core 1 and prepreg reinforcement layer 2 form the apron, the skirt on the upper side of the skirt is called the upper skin, and the skirt on the lower side of the skirt is called the lower skin; the lower skin From the outside to the inside, it includes the first edging layer 3, the second A edging layer 4, the second B edging layer 5, the third A edging layer 6, and the third B edging layer 7; From inside to outside, the upper skin includes the first A full layup 8, the first B full layup 9, the first A reduced layup 10, the first B reduced layup 11, the second A reduced layup 12, the first A reduced layup The second B reduction ply 13, the second full ply 14 and the fourth edge-wrapped ply 15; the third B-wrapped ply 7 is in contact with the bottom surface of the apron, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com