Preparation method of lubricating oil added with nanomaterial

A technology of nanomaterials and lubricating oils, applied in the direction of additives, lubricating compositions, petroleum industry, etc., can solve the problems of high specific surface area and surface energy, small size of nanomaterials, poor dispersion stability, etc., so as to improve the lubrication effect and reduce the Mold loss and the effect of improving the service life of the mold

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

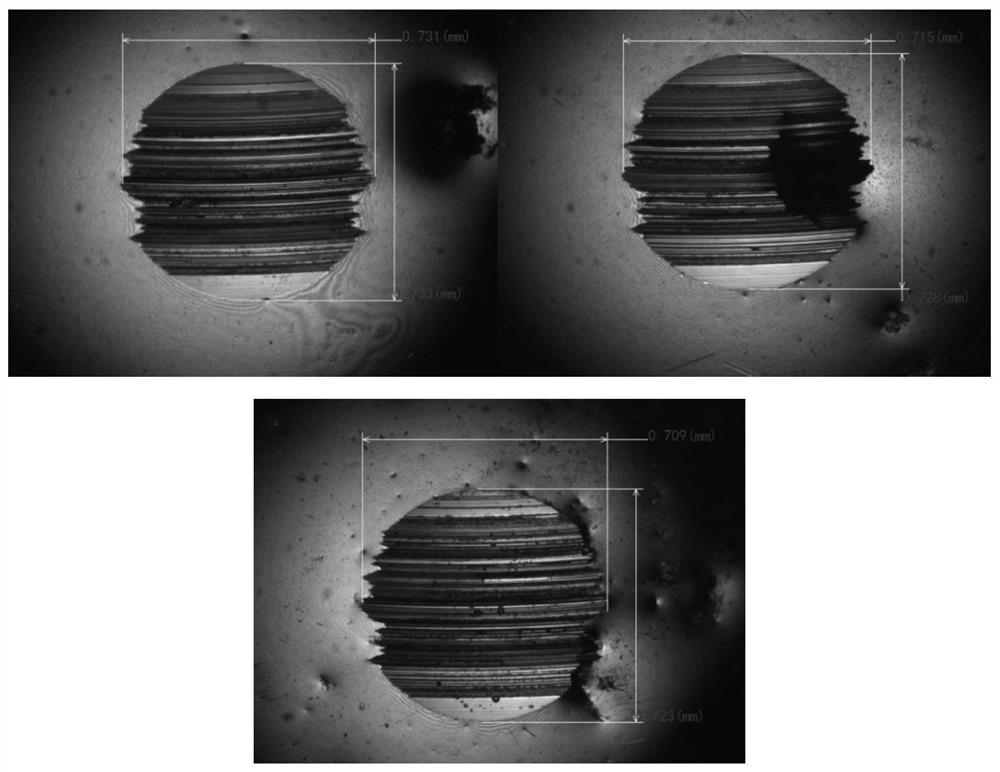

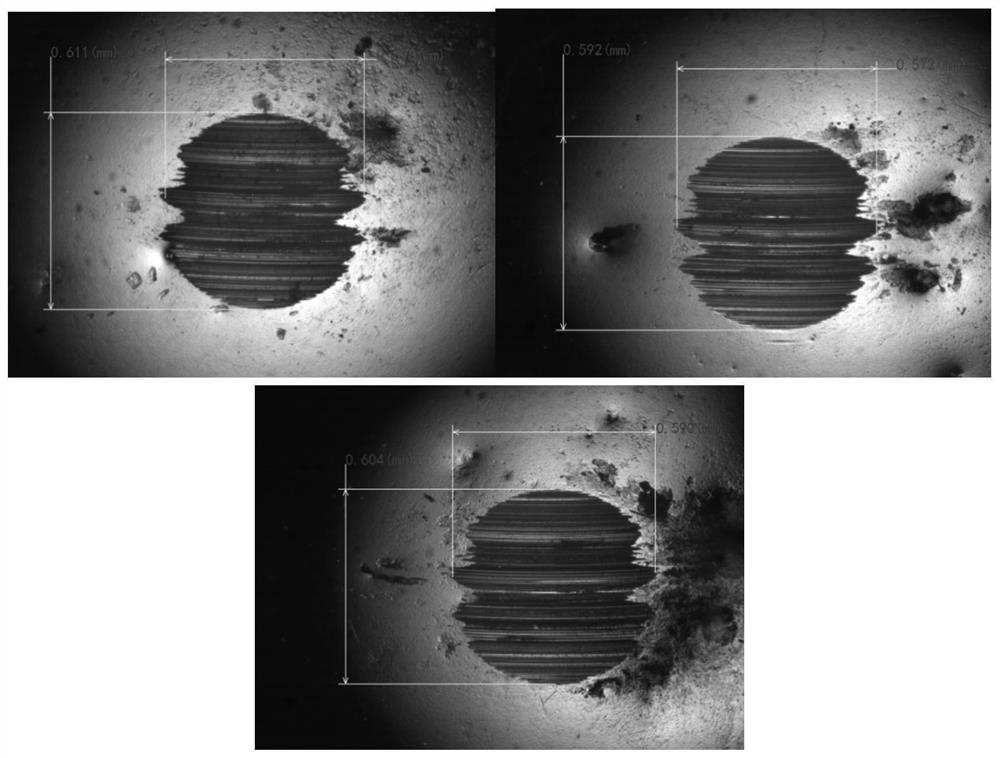

Image

Examples

Embodiment 1

[0033] Dodecyl mercaptan is used as active modifier, molybdenum disulfide nanosheets are used as layered nanosheets as nano additives, and rapeseed oil is used as base oil of lubricating oil. Including the following production steps:

[0034] (1) 10g of nanosheet powder and 50g of n-dodecanethiol are added to 1000mL of absolute ethanol, fully stirred and mixed, and the weight ratio of nanosheet to active modifier is 1:1; the mixture is passed through a 300W motor Ultrasonic equipment was used for ultrasonic vibration treatment at 60° C. for 10 hours, and then stirred at room temperature for 5 hours to obtain a mother solution of nanosheets grafted with an active modifier.

[0035] (2) The above-mentioned nanosheet mother liquor was filtered through a vacuum filtration device, and washed repeatedly with absolute ethanol 3 times to remove the residual active modifier, and the product was vacuum-dried at 40° C. for 2 hours to obtain modified nanosheets.

[0036] (3) Add the abov...

Embodiment 2

[0039] Dodecyl mercaptan is used as active modifier, molybdenum disulfide nanosheets are used as layered nanosheets as nano additives, and rapeseed oil is used as base oil of lubricating oil. Including the following production steps:

[0040] (1) 10g of nanosheet powder and 50g of n-dodecanethiol are added to 1000mL of absolute ethanol, fully stirred and mixed, and the weight ratio of nanosheet to active modifier is 1:5; the mixture is passed through a 300W motor Ultrasonic equipment was used for ultrasonic vibration treatment at 60° C. for 10 hours, and then stirred at room temperature for 5 hours to obtain a mother solution of nanosheets grafted with an active modifier.

[0041] (2) The above-mentioned nanosheet mother liquor was filtered through a vacuum filtration device, and washed repeatedly with absolute ethanol 3 times to remove the residual active modifier, and the product was vacuum-dried at 40° C. for 2 hours to obtain modified nanosheets.

[0042] (3) Add the abov...

Embodiment 3

[0045] Dodecyl mercaptan is used as active modifier, molybdenum disulfide nanosheets are used as layered nanosheets as nano additives, and rapeseed oil is used as base oil of lubricating oil. Including the following production steps:

[0046] (1) 10g of nanosheet powder and 50g of n-dodecanethiol are added to 1000mL of absolute ethanol, fully stirred and mixed, and the weight ratio of nanosheet to active modifier is 1:8; the mixture is passed through a 300W motor Ultrasonic equipment was used for ultrasonic vibration treatment at 60° C. for 10 hours, and then stirred at room temperature for 5 hours to obtain a mother solution of nanosheets grafted with an active modifier.

[0047] (2) The above-mentioned nanosheet mother liquor was filtered through a vacuum filtration device, and washed repeatedly with absolute ethanol 3 times to remove the residual active modifier, and the product was vacuum-dried at 40° C. for 2 hours to obtain modified nanosheets.

[0048] (3) Add the abov...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com