Artificial soft tissue braided fabric, preparation method and application thereof

A braided and soft tissue technology, applied in the field of medical and surgical repair materials, can solve the problems of inability of cells in the middle dense part to grow in, unable to meet mechanical requirements, etc., achieve good biocompatibility, promote adhesion growth, and enhance growth and proliferation. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

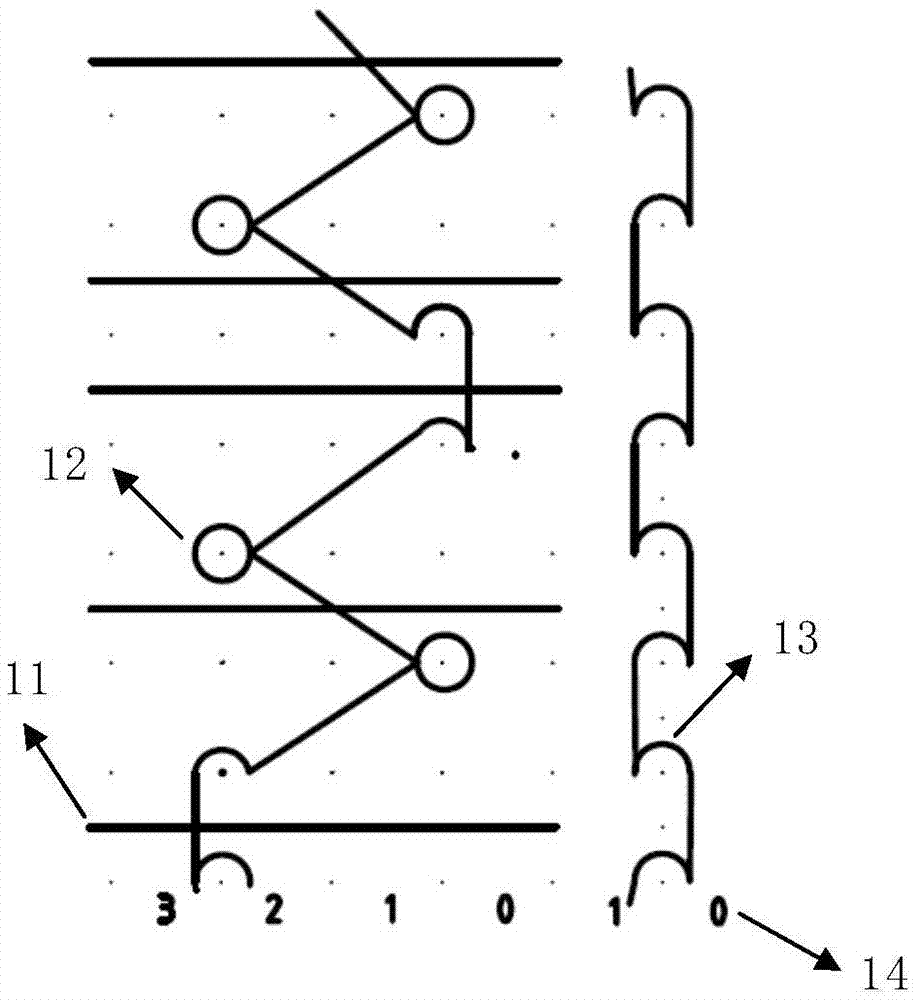

[0059] Fabrication of ultra-high-strength and low-model artificial soft tissue braids

[0060] Weaving method (see attached figure 2 ):

[0061] Organization process:

[0062] Front comb GB1: 1-0 / 0-1 / / full wear

[0063] Back comb GB2:2-3 / 3-2 / 1-0 / 2-3 / 1-0 / 0-1 / 2-3 / 1-0 / / full wear

[0064] Full weft insertion: 2 threads, 1 empty, 1 thread, 1 empty, 2 threads, 1 empty.

[0065] Weft direction: Lining yarn (PET: PEHM=0:1), that is, weft insertion yarn is only composed of PEHM; Silk, the surface is basically covered by silk, and the inner layer is a sandwich structure of synthetic fiber silk.

[0066] In this embodiment, the sandwich structure is that the upper surface layer 100 is composed of silk, the middle layer 200 is composed of PET, the inner layer 300 is composed of PEHM, the middle layer 400 is composed of PET, and the lower surface layer 500 is composed of silk. The middle layer 200, the inner layer 300 and the middle layer 400 composed of synthetic fiber silk are use...

Embodiment 2

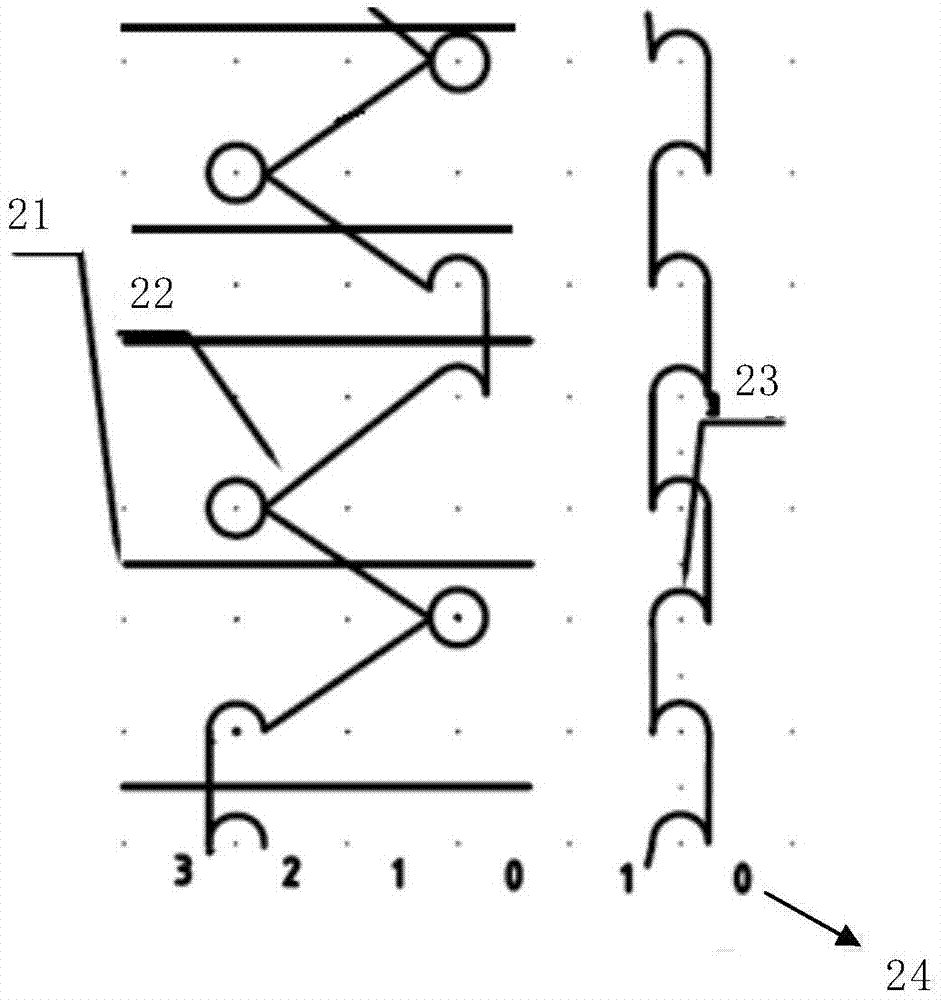

[0068] Fabrication of high-strength low-model artificial soft tissue braids

[0069] Weaving method (see attached image 3 )

[0070] Organization process:

[0071] Front comb GB1: 1-0 / 0-1 / / full wear

[0072] Back comb GB2:2-3 / 3-2 / 1-0 / 2-3 / 1-0 / 0-1 / 2-3 / 1-0 / / full wear

[0073] Full weft insertion: 2 threads, 1 empty, 1 thread, 1 empty, 2 threads, 1 empty.

[0074] Weft direction: cushion yarn (PET: PEHM=1:1); warp direction: front comb silk weave for chain weave, back comb PET weave for changing warp and satin weave; front comb is made of silk, the surface is basically covered by silk , the inner layer is a sandwich structure of synthetic fiber silk.

[0075] In this embodiment, the sandwich structure is that the upper surface layer 100 is made of silk, the middle layer 200 is made of PET, and the inner layer 300 is made of PEHM or PET (that is, in the sections of different positions, the inner layer 300 may be PEHM or PET), the middle layer 400 is composed of PET, and the ...

Embodiment 3

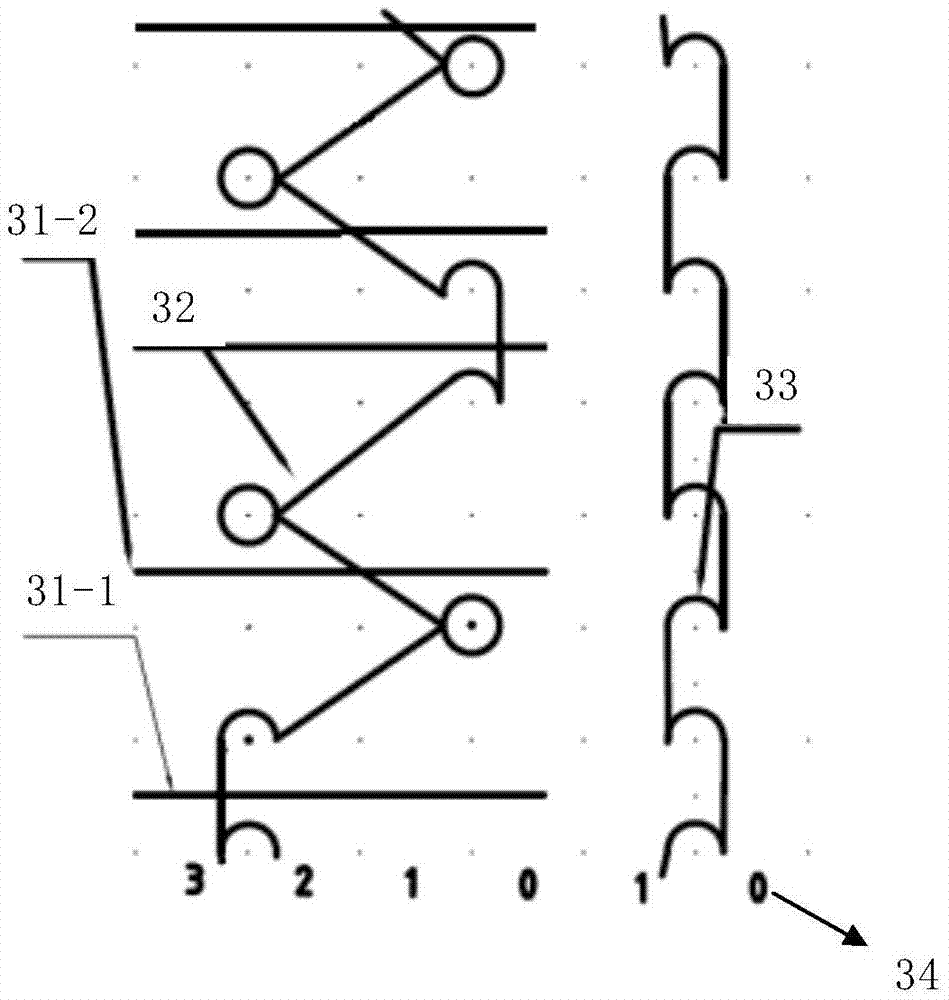

[0077] Preparation of high-strength, low-modulus and large-porosity artificial soft tissue braids

[0078] Weaving method (see attached Figure 4 ):

[0079] Organization process:

[0080] Front comb GB1: 1-0 / 0-1 / / full wear

[0081] Back comb GB2:2-3 / 3-2 / 1-0 / 2-3 / 1-0 / 0-1 / 2-3 / 1-0 / / full wear

[0082] Full weft insertion: 2 threads, 1 empty, 1 thread, 1 empty, 2 threads, 1 empty.

[0083] Weft direction: Lining yarn (PET: PEHM: SILK=2:2:1), Warp direction: Front bar silk and chemical fiber (PET, PEHM) are alternately woven to make chain weave, back comb uses PET: PEHM: SILK = 1:1:1 weaving, changing warp and satin weave. Through reasonable yarn threading, one chemical fiber loop and one SILK loop are realized in the warp direction. Due to the degradation of silk fibers, the fabric becomes more porous. The fabric of this design has the characteristics of high strength, low modulus, and low creep.

[0084] In this embodiment, the upper surface layer 100 of the sandwich struc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com