Sludge low-temperature drying treatment system

A treatment system and sludge drying technology, applied in the direction of dehydration/drying/thickened sludge treatment, etc., can solve the problems of high energy consumption, secondary pollution of the environment, and high operating costs, and achieve reduced resistance, small footprint, The effect of high degree of equipment integration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The present invention will be described in detail below in conjunction with the embodiments shown in the drawings, but it should be noted that these embodiments are not a limitation of the present invention, and those of ordinary skill in the art make functional, method, or structural improvements based on these embodiments. Equivalent changes or substitutions fall within the protection scope of the present invention.

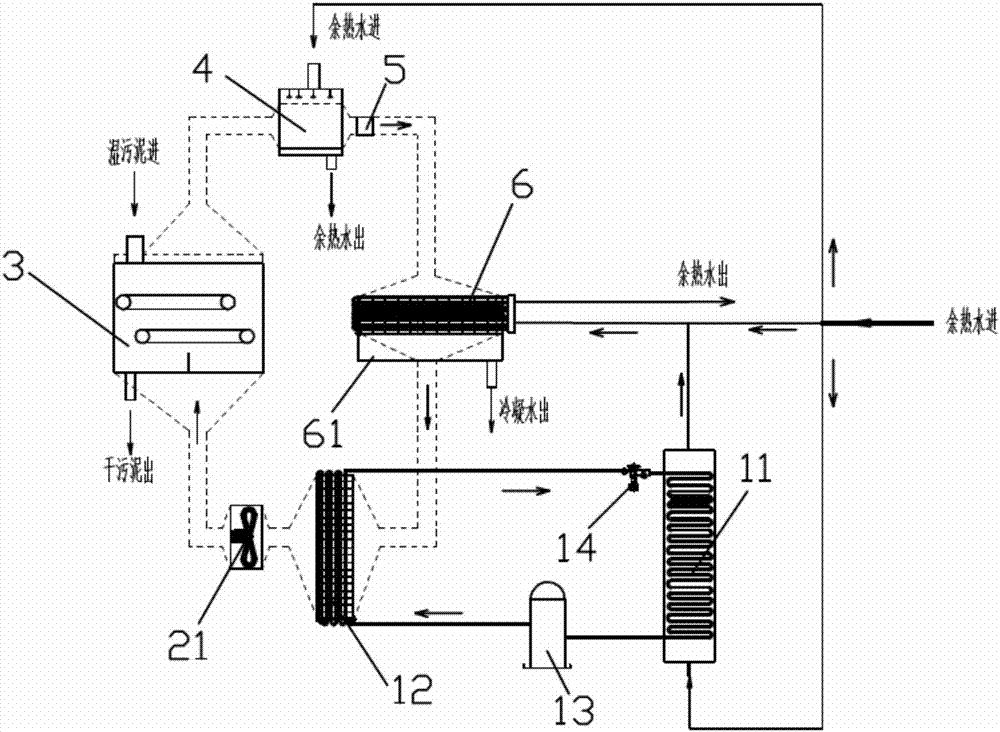

[0016] Participate figure 1 As shown, this embodiment provides a low-temperature sludge drying treatment system, including a heat pump system, an air circulation system, a sludge drying chamber 3, a spray system 4, a filter 5, and a surface cooler 6; the heat pump system includes The evaporator 11, the condenser 12, the compressor 13 and the expansion valve 14. The evaporator 11 is connected to the condenser 12 through the compressor 13 and the expansion valve 14. The evaporator 11 is used to absorb heat from the water in the sewage treatment plant and pass ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com