A preparation method and preparation device of xteo2·p2o5 (x=2,4) crystal

A te2p2o9, crystal technology, applied in the field of preparation of nonlinear optical crystal xTeO2·P2O5, can solve the problems of difficult control, phase transition, decomposition, etc., and achieve the effect of simple growth conditions, simple device structure and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

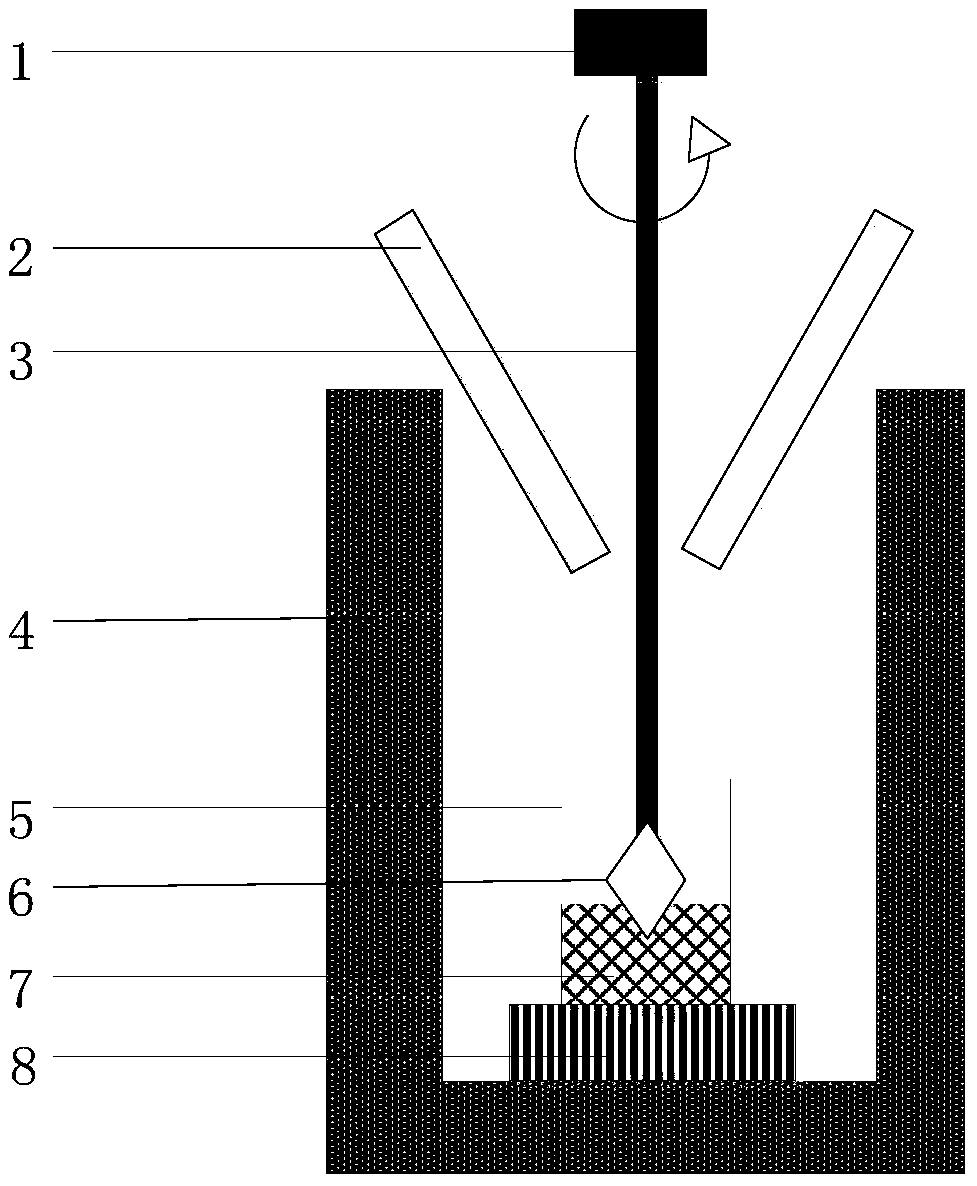

[0037] a xTeO 2 ·P 2 o 5 (x=2, 4) The crystal preparation device includes a growth furnace 4, the top of the growth furnace 4 is open, and the inner bottom of the growth furnace 4 is provided with an insulation layer 8, and the above insulation layer 8 is provided with The crucible 5, the top of the growth furnace 4 is obliquely provided with an observation hole 2, the center of the growth furnace 4 is provided with a seed rod 3, and the seed rod 3 is connected with a pulling device 1.

[0038] When the preparation device of this embodiment is used, the TeO 2 and P 2 o 5 Raw materials are put into crucible 5, start growth furnace 4, TeO 2 and P 2 o 5 The raw material is melted in the crucible 5 to obtain the melt 7, the pulling device 1 is started, and the seed crystal is obtained at the end of the seed rod 3; then the TeO 2 and P 2 o 5 The raw materials are put into the crucible 5, the crystallization temperature and the pulling rate are controlled to grow the cryst...

Embodiment 2

[0040] Growth of Te by pulling method 2 P 2 o 9 Crystals, including steps as follows:

[0041] (1) Platinum wire pulling to prepare seed crystal

[0042] TeO 2 and P 2 o 5 Raw materials are mixed evenly at a molar ratio of 2:1; put into a platinum crucible and heat up to 750°C, keep the temperature for 3 hours, the material is fully melted and the melt is mixed evenly; then pulled at a rate of 5mm / hour to obtain Te 2 P 2 o 9 Crystals, used to make seed crystals;

[0043] (2) Growth of Te by pulling method 2 P 2 o 9 the crystal

[0044] Preparation of Te by pulling method 2 P 2 o 9 The main growth conditions of the crystal are: a platinum crucible is used for growth in air, the growth temperature is 650-680° C., and the pulling rate is 0.2-1 mm / hour.

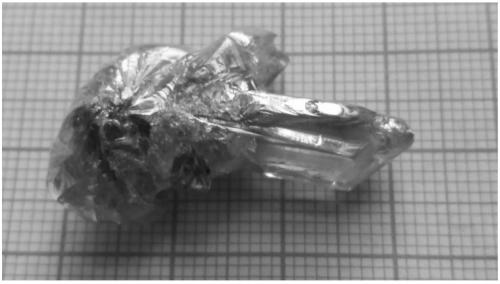

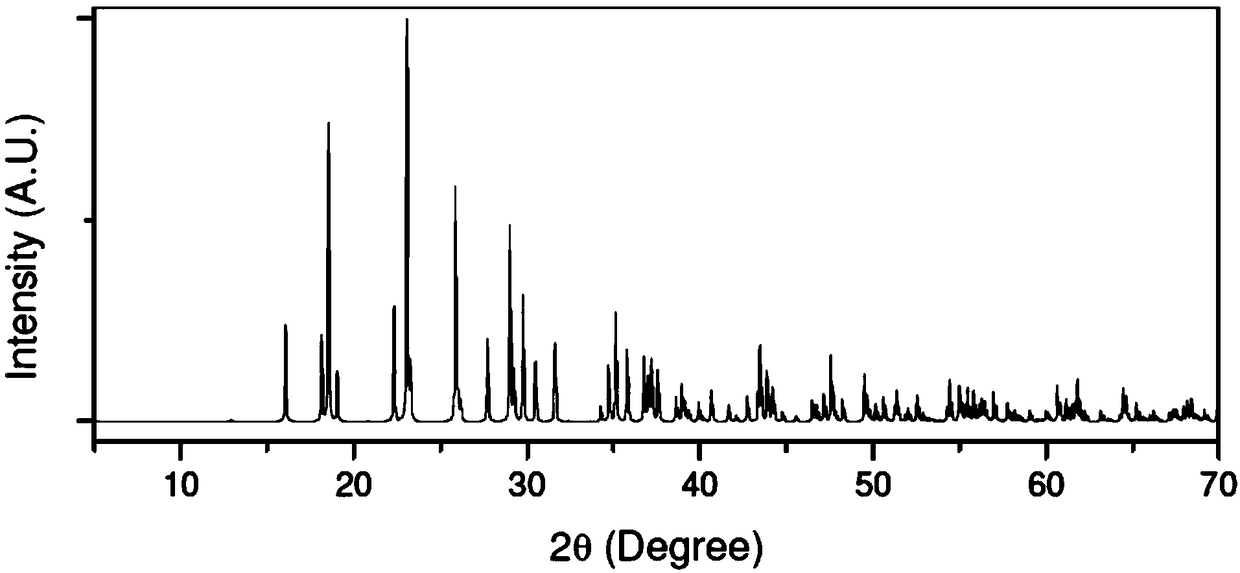

[0045] TeO 2 and P 2 o 5 The raw materials are mixed evenly at a molar ratio of 2:1; put into a platinum crucible and heat up to 750°C, overheat at a constant temperature for 3 hours to fully melt the material ...

Embodiment 3

[0050] Growth of Te by pulling method 4 P 2 o 13 Crystals, including steps as follows:

[0051] (1) Platinum wire pulling to prepare seed crystal

[0052] TeO 2 and P 2 o 5 The raw materials are mixed evenly at a molar ratio of 4:1; put into a platinum crucible and heat up to 650°C, keep the temperature for 4 hours, the material is fully melted and the melt is mixed evenly; then pulled at a rate of 5mm / hour to obtain Te 4 P 2 o 13 Crystals, used to make seed crystals;

[0053] (2) Growth of Te by pulling method 4 P 2 o 13 the crystal

[0054] Preparation of Te by pulling method 4 P 2 o 13 The main growth conditions of the crystal are: a platinum crucible is used for growth in air, the growth temperature is 590-600° C., and the pulling rate is 0.2-0.8 mm / hour.

[0055] TeO 2 and P 2 o 5 The raw materials are mixed evenly at a molar ratio of 4:1; put into a platinum crucible and heat up to 650°C, overheat at a constant temperature for 4 hours, so that the mate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com