A cartridge separation device for a large submersible deep underwater non-powered launch delivery system

A separation device and launcher technology, applied in torpedo launchers, offensive equipment, weapon types, etc., can solve problems such as the inability to meet the sealing requirements, the problem of heat protection of the launcher, and the complex structure, so as to solve the problem of heat protection and avoid long-term problems. Time wash, improve concealment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

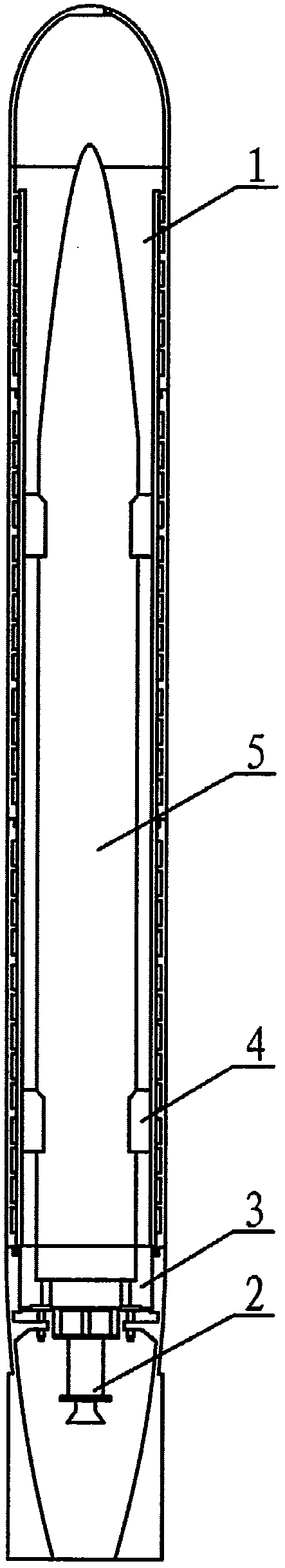

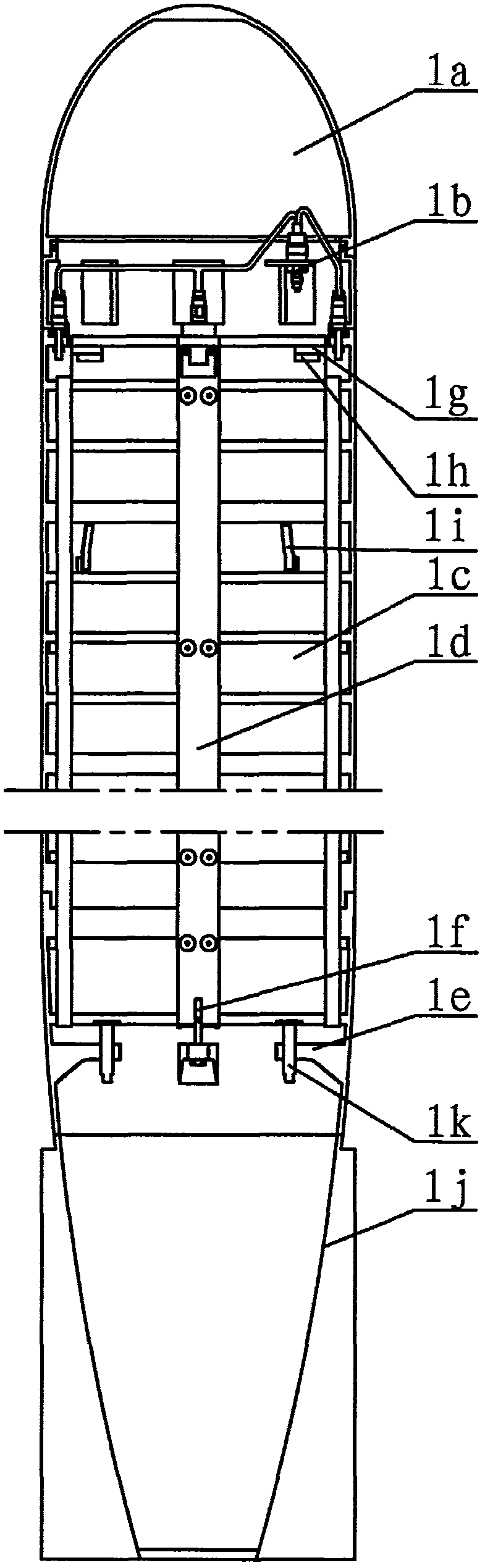

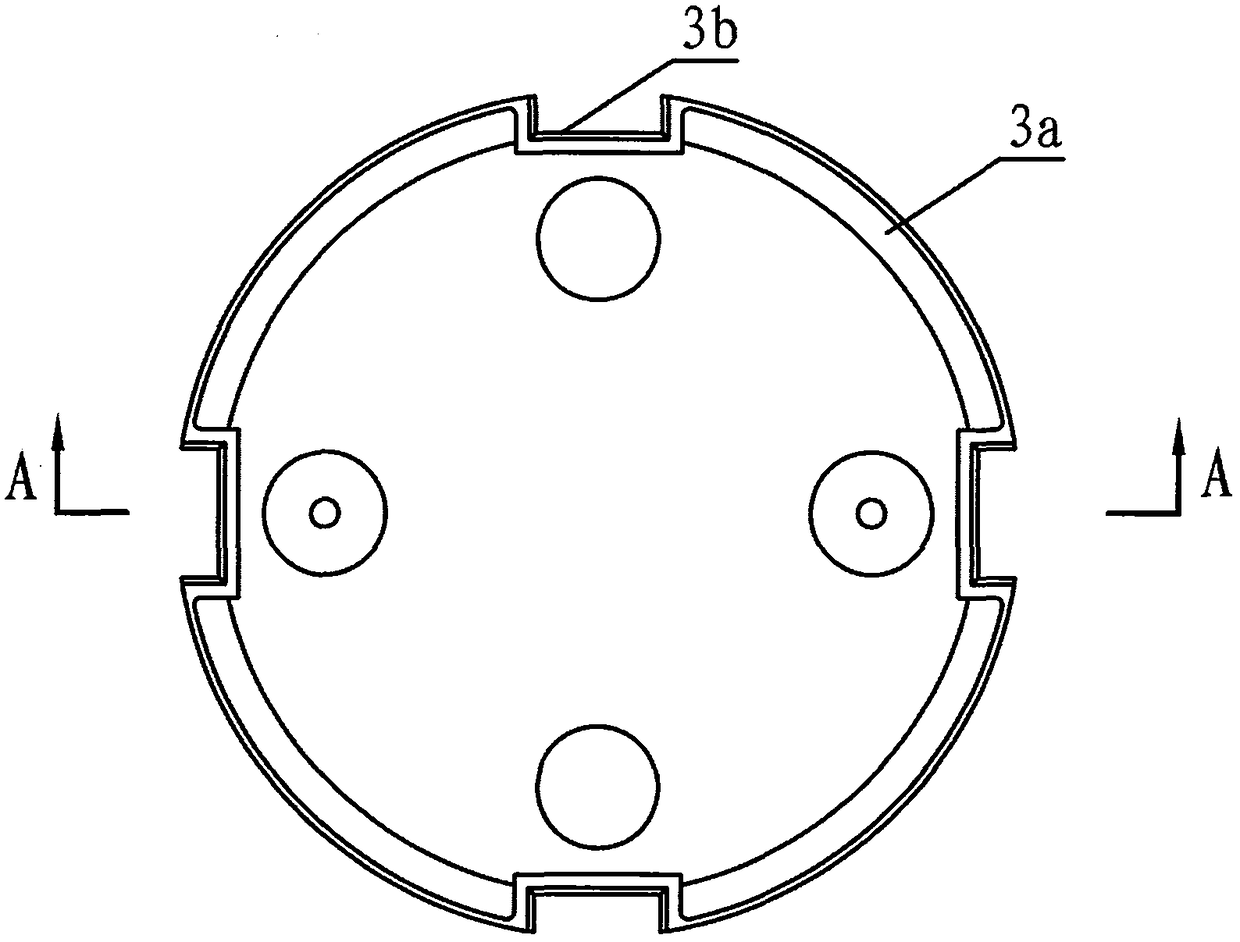

[0019] Such as figure 1 It is a structural schematic diagram of the cartridge separating device of the large submerged deep underwater unpowered launch delivery system of the present invention, including a launch tube 1 provided with a front cover 1a, a sealing base plate 3 arranged in the launch tube 1, and a catapult 2. The catapult 2 is Gas generator, the jet is pure gas, the catapult 2 is fixed on one side of the sealed bottom plate 3, the other side of the sealed bottom plate 3 is attached to the tail end of the missile 5 (the missile 5 is installed in the launch tube 1), and the sealed bottom plate 3 can slide along the launch tube 1, and the launch tube 1 is also equipped with a cover opening mechanism 1b for opening the front cover 1a. The thrust generated by the catapult 2 pushes the sealing bottom plate 3 and then pushes the tail end of the missile 5 to make the missile 5 cover forward along the launch tube 1 Sliding in the direction of 1a, the missile 5 slides and s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com