Target knife utilizing laser surface texture optimization

A technology of surface texture and laser phase change hardening, which is applied in the field of targeted knives, can solve problems such as improving the surface performance of the knife body, and achieve improved freezing and ablation effects, improved wear resistance and high temperature oxidation resistance, and friction Reduced effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

[0017] Such as figure 1 As shown, a targeted knife using laser surface texture optimization, including a stainless steel targeting knife body 1, the surface of the targeted knife body has an optimized surface tissue layer 2 through laser phase transformation hardening or laser remelting, so that the surface of the knife body obtains an extremely Fine hardened tissue improves the wear resistance and high temperature oxidation resistance of the knife body surface, reduces the friction between the knife body and human tissue, improves the effect of freezing and ablation, thereby reducing the knife edge and reducing the patient's pain.

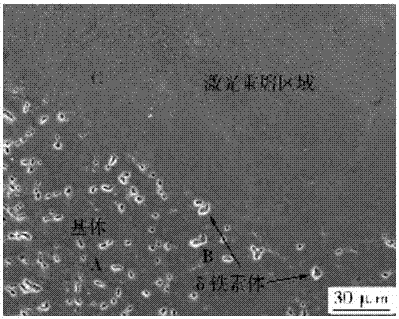

[0018] Laser phase transformation hardening is widely used in the field of material surface modification due to its high power density, high surface strengthening quality, small impact on the original during processing, par...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com