Automatic efficient filtration residue concentration filter

A filter and high-efficiency technology, applied in the field of water treatment, can solve the problems of fast clogging of filter holes by filter residues, less backwashing times and water consumption, and more clean water, etc., achieving less water consumption and less backwashing times. , the effect of large water output

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

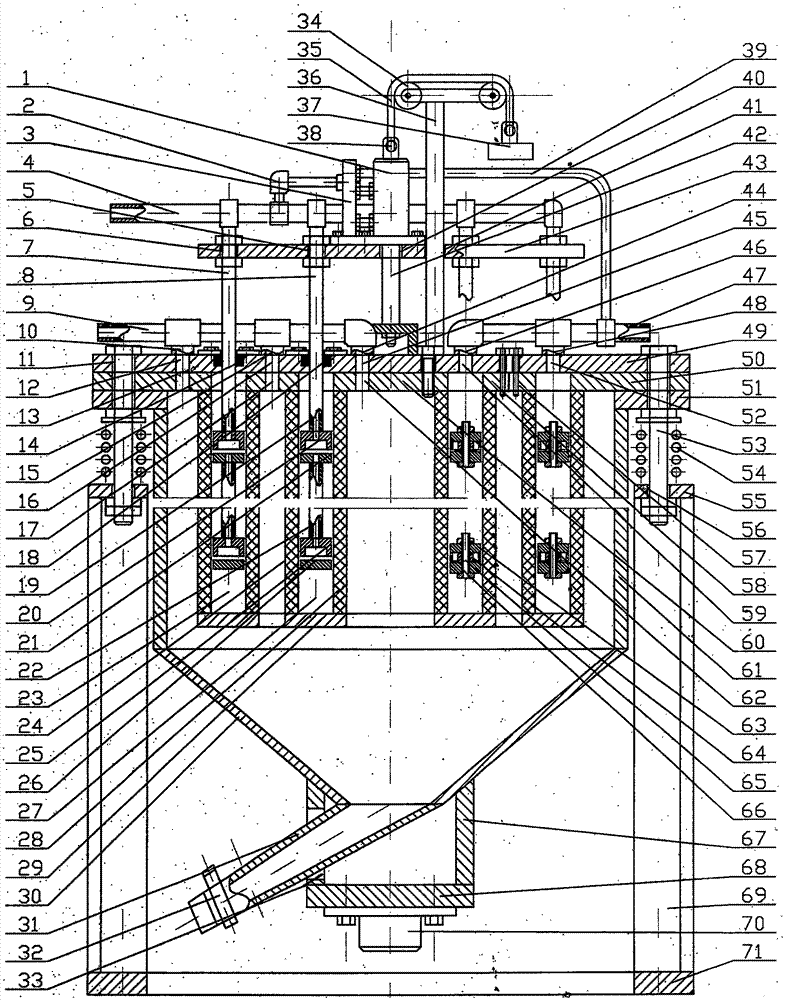

[0008] The present invention mainly consists of cylinder body (61), several two-way filter screen cylinder one (27), recoil device one (8), hydraulic cylinder (1), electromagnetic vibrator (70), slag discharge pipe (31), electromagnetic The valve (32), the water inlet pipe (9) and the water outlet pipe (47) are composed of a cylindrical body (61) with an upper flange (51) on the upper end and fixedly connected to each other by welding, and an upper flange (51) on the lower end. The slag collection hoppers (30) with large and small conical shapes are fixedly connected to each other by welding, and support pipes (67) are arranged below the slag collection hoppers (30) and are fixedly connected to each other by welding, and the walls of the support pipes (67) are provided with large passages. Hole (33), its lower end is provided with support plate (68) and mutually fixedly connected with welding mode, and support plate (68) below is provided with electromagnetic vibrator (70) and ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com