A kind of sulfur-fixing ash slag cement and preparation method thereof

A technology for sulfur-fixing ash and sulfur-fixing slag is applied in the field of cement cementitious materials, which can solve the problems of large water demand and self-hardening, effective utilization of cement production, etc., and achieves cost reduction, good social and economic benefits, and large-scale The effect of absorption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0019] (1) Preparation of sulfur-fixed ash powder: The sulfur-fixed ash that meets the standard of "Fly Ash Used in Cement and Concrete" (GB / T1596-2005) is ground with a power plant waste heat steam kinetic energy mill, and the specific surface area is 1004m 2 / kg.

[0020] (2) Preparation of sulfur-fixing slag powder: Grind the sulfur-fixing slag finely with a cement ball mill. Sieve residue) was 16.7%.

[0021] (3) Preparation of Portland cement clinker powder: The Portland cement clinker that meets the "General Portland Cement" (GB175-2007) standard is ground with a cement ball mill, and the fineness (45 μm square hole sieve Sieve residue) was 14.5%.

[0022] (4) Preparation of desulfurized gypsum powder: after drying the desulfurized gypsum at room temperature, it was ground with a cement ball mill to a fineness (45 μm square hole sieve residue) of 12.6%.

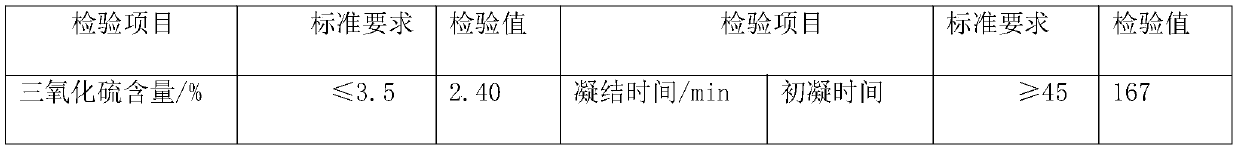

[0023] Preparation of P F42.5 cement: According to the formula of material dosage, sulfur-fixing ash powder 40; s...

Embodiment 2

[0030] (1) Preparation of sulfur-fixed ash powder: The sulfur-fixed ash that meets the standard of "Fly Ash Used in Cement and Concrete" (GB / T1596-2005) is ground with a power plant waste heat steam kinetic energy mill, and the specific surface area is 1121m 2 / kg.

[0031] (2) Preparation of sulfur-fixing slag powder: Grind the sulfur-fixing slag finely with a cement ball mill. Sieve residue) was 15.2%.

[0032] (3) Preparation of Portland cement clinker powder: The Portland cement clinker that meets the "General Portland Cement" (GB175-2007) standard is ground with a cement ball mill, and the fineness (45 μm square hole sieve Sieve residue) was 12.3%.

[0033] (4) Preparation of desulfurized gypsum powder: after drying the desulfurized gypsum at room temperature, it was ground with a cement ball mill to a fineness (45 μm square hole sieve residue) of 12.8%.

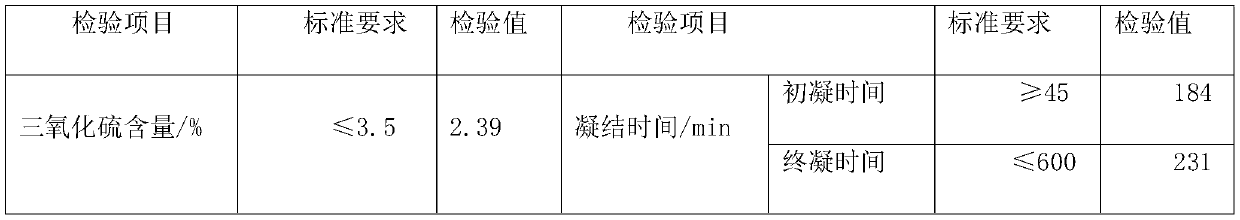

[0034] Preparation of P F42.5 cement: According to the formula of material dosage, sulfur-fixing ash powder 50; s...

Embodiment 3

[0041] (1) Preparation of sulfur-fixed ash powder: The sulfur-fixed ash that meets the standard of "Fly Ash Used in Cement and Concrete" (GB / T1596-2005) is ground with a power plant waste heat steam kinetic energy mill, and the specific surface area is 1054m 2 / kg.

[0042] (2) Preparation of mixed powder consisting of sulfur-fixing slag, Portland cement clinker and desulfurized gypsum: based on the total mass of the prepared cement, 28% of sulfur-fixing slag, 34% of Portland cement clinker, and desulfurized gypsum 3% weighing; after it is mixed, it is ground with a cement ball mill, and the fineness of the mixed powder (45 μm square hole sieve) is 14.1%;

[0043] Preparation of P·F42.5 cement: Based on the total mass of prepared cement, weigh 35% of sulfur-fixed ash powder and 65% of the above-mentioned mixed powder, and mix them evenly.

[0044] The cement inspection result and quality of embodiment 3 are shown in Table 3.

[0045] The cement inspection result of table 3 ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com