High-efficiency retarding water reducer for concrete and preparation method thereof

A technology of retarder and water reducer, which is applied in the field of concrete retarder and water reducer, can solve the problems of corroded steel structure, unfavorable construction, low production efficiency, etc., and achieves the effect of increasing strength and not easy to coagulate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

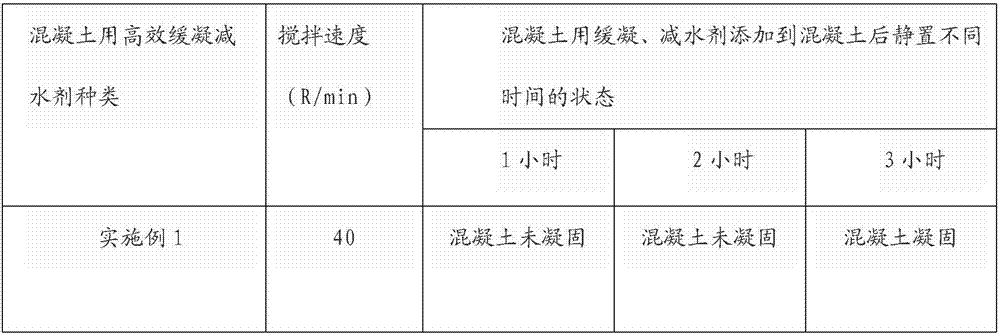

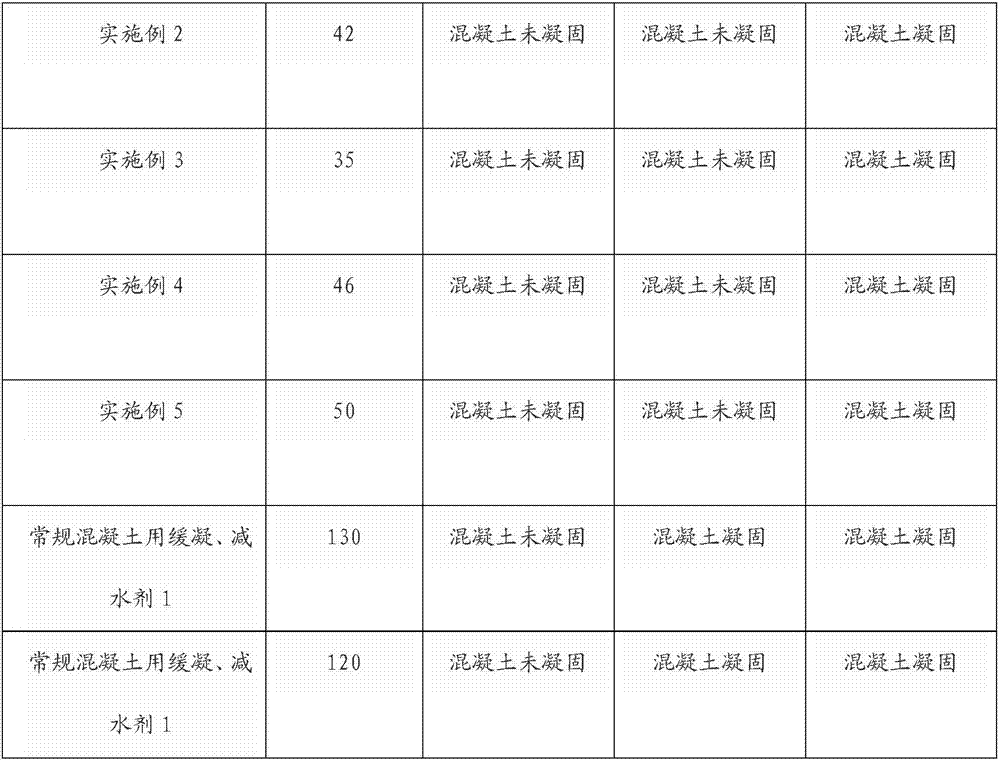

Examples

Embodiment 1

[0018] High-efficiency retarding and water reducing agent for concrete, the composition is as follows:

[0019] Including water reducer A, retarder B, retarder C and shrinkage reducer D, the ratio of water reducer A, retarder B, retarder C and shrinkage reducer D is 1200:20:10:1; Water agent A includes by weight: 1200 parts of naphthalene sulfonate formaldehyde condensate water reducer, 400 parts of amino acid salt and alkali water agent; retarder B includes 90 parts by weight of castor oil; retarder C by weight The parts include: 300 parts of calcium carbonate, 64 parts of citric acid, and 50 parts of sodium tripolyphosphate. Shrinkage reducing agent D includes 2 parts by weight of cellulose ether.

[0020] The preparation method of the pesticide emulsifier of the present invention is as follows, including the following steps:

[0021] ①Preparation of water reducer A: Mix and stir the naphthalene sulfonate formaldehyde condensate water reducer and amino acid salt and alkali water ...

Embodiment 2

[0027] High-efficiency retarding and water reducing agent for concrete, the composition is as follows:

[0028] Including water reducer A, retarder B, retarder C and shrinkage reducer D, the ratio of water reducer A, retarder B, retarder C and shrinkage reducer D is 1200:20:10:1; Aqueous agent A includes by weight: 1400 parts of naphthalene sulfonate formaldehyde condensate water reducer and 500 parts of amino acid salt-alkali aqueous agent; retarder B includes 100 parts by weight of castor oil; retarder C by weight The parts include: 400 parts of calcium carbonate, 74 parts of citric acid, and 60 parts of sodium tripolyphosphate. Shrinkage reducing agent D includes 3 parts by weight of cellulose ether.

[0029] The preparation method of the pesticide emulsifier of the present invention is as follows, including the following steps:

[0030] ①Preparation of water reducer A: Mix and stir the naphthalene sulfonate formaldehyde condensate water reducer and amino acid salt and alkali wa...

Embodiment 3

[0036] High-efficiency retarding and water reducing agent for concrete, the composition is as follows:

[0037] Including water reducer A, retarder B, retarder C and shrinkage reducer D, the ratio of water reducer A, retarder B, retarder C and shrinkage reducer D is 1200:20:10:1; Water agent A includes by weight: 1300 parts of naphthalenesulfonate formaldehyde condensate water reducer, 450 parts of amino acid salt and alkali water agent; retarder B includes: 95 parts by weight of castor oil; retarder C by weight Servings include: 350 parts of calcium carbonate, 70 parts of citric acid, and 55 parts of sodium tripolyphosphate. Shrinkage reducing agent D includes 2 parts by weight of cellulose ether.

[0038] The preparation method of the pesticide emulsifier of the present invention is as follows, including the following steps:

[0039] ①Preparation of water reducer A: Mix and stir the naphthalene sulfonate formaldehyde condensate water reducer and amino acid salt and alkali water a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com