Preparation method of polyvinylamine

A technology of polyvinylamine and polyacrylamide, which is applied in the field of preparation of polyvinylamine, can solve the problems of small molecular weight, waste, and low concentration of reactants, and achieve the effects of reducing surface tension, reducing waste liquid discharge, and improving quality indicators

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

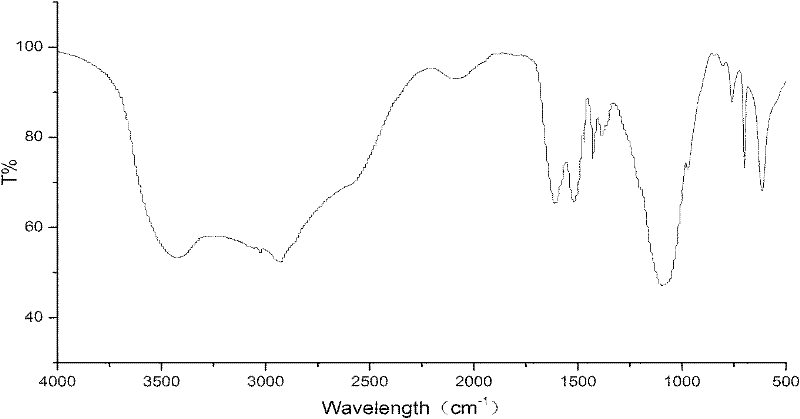

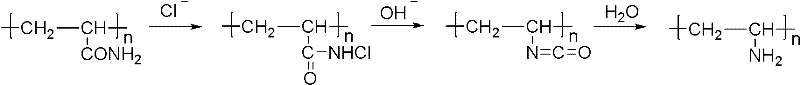

Image

Examples

Embodiment 1

[0024] Add 26ml of 15% NaOH solution into a 250mL three-necked flask and cool to -5°C, then add 56mL of 12.6% NaClO solution, add 0.25g of non-ionic surface-active nonylphenol polyoxyethylene ether and stir. At -5°C, add 7.1 g of polyacrylamide with a molecular weight of 600,000 to 1,000,000 in small amounts in 5 times, and stir while adding. Continue stirring for 1.5 h after the material dissolves to obtain a chlorinated amide solution.

[0025] Prepare 300 mL of sodium hydroxide solution with a concentration of 40%, and slowly add the obtained chlorinated intermediate solution at 30 mL / min under stirring at -5°C, and continue stirring for 6 h after the addition is complete. After the reaction was completed, the liquid phase was put into 4 times the volume of methanol to precipitate a solid, which was rinsed with methanol for suction filtration, and the filter cake was dried. Alkali-containing reaction mother liquor is distilled to recover methanol, and then after concentrat...

Embodiment 2

[0028] Add 26ml of 15% NaOH solution into a 250mL three-necked flask and cool to -5°C, then add 56mL of 12.6% NaClO solution, add 0.3g of polyoxyethylene lauryl ether and stir. At -5°C, add 7.1 g of polyacrylamide with a molecular weight of 600,000 to 1,000,000 in batches, and stir while adding. After the material was dissolved, the stirring was continued for 1 h to obtain a chlorinated amide solution.

[0029] After analyzing the sodium hydroxide recovered in Example 1, add sodium hydroxide so that the concentration reaches 40%, and under stirring at -5°C, slowly add the obtained chlorinated intermediate reaction solution at 30mL / min, after adding The stirring reaction was continued for 6h. After the reaction was completed, the liquid phase was put into 4 times the volume of methanol to precipitate a solid, which was rinsed with methanol for suction filtration, and the filter cake was dried. The reaction mother liquor containing alkali and methanol is recovered and recycled. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com