Axial flow fan

An axial-flow fan and axial-flow wind technology, applied in mechanical equipment, machines/engines, liquid fuel engines, etc., can solve problems such as reducing the noise level of household appliances, reduce working speed and noise, increase air supply air volume, and improve performance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

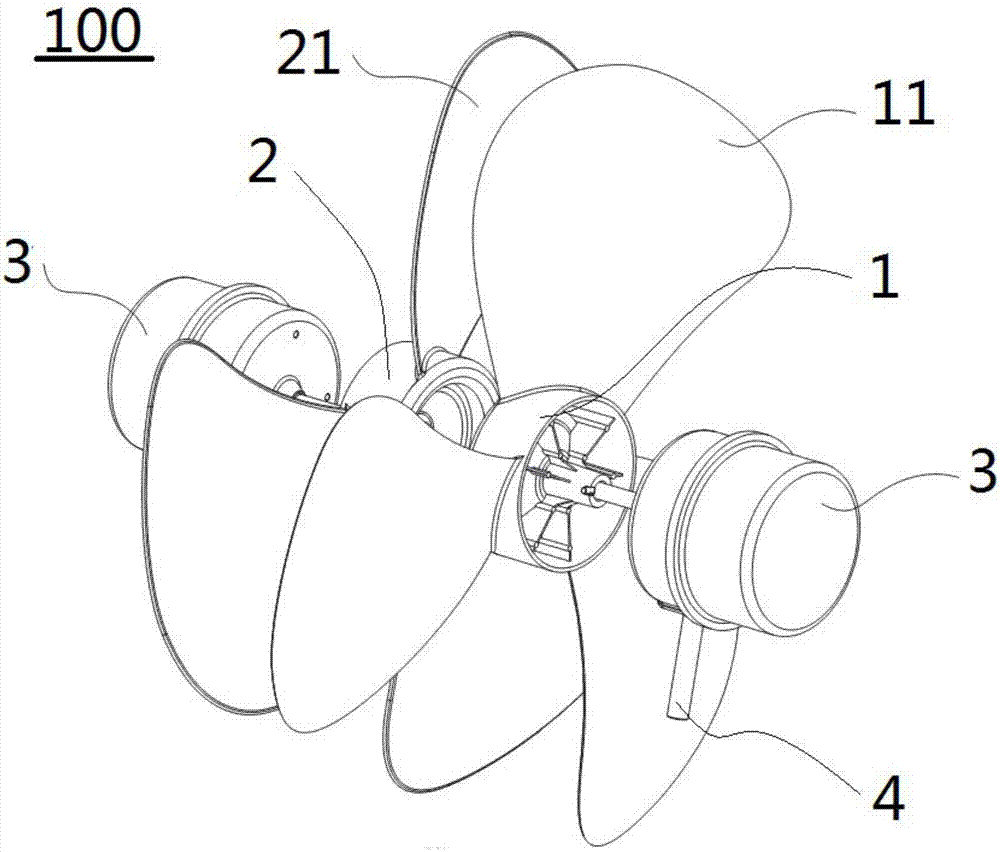

[0049] Such as figure 1 As shown, the axial flow fan 100 of the present invention mainly includes a first axial flow wind wheel 1, a second axial flow wind wheel 2 and two drive motors 3, and the two drive motors 3 are respectively connected to other structures such as a housing through a bracket 4 Connected, the first axial flow wind wheel 1 and the second axial flow wind wheel 2 are located between two drive motors 3 . The first fan blade 11 is arranged on the first axial flow wind wheel 1, and the second fan blade 21 is arranged on the second axial flow wind wheel 2. The first fan blade 11 utilizes a shaft end nut and a pin and a drive motor 3 close to it. The rotation direction is clockwise. The second fan blade 21 is connected and fixed with the drive motor 3 close to it by using the shaft end nut and pin. The rotation direction is counterclockwise. The bending direction of the first fan blade 11 is Opposite to the bending direction of the second blade 21, in the axial d...

Embodiment 2

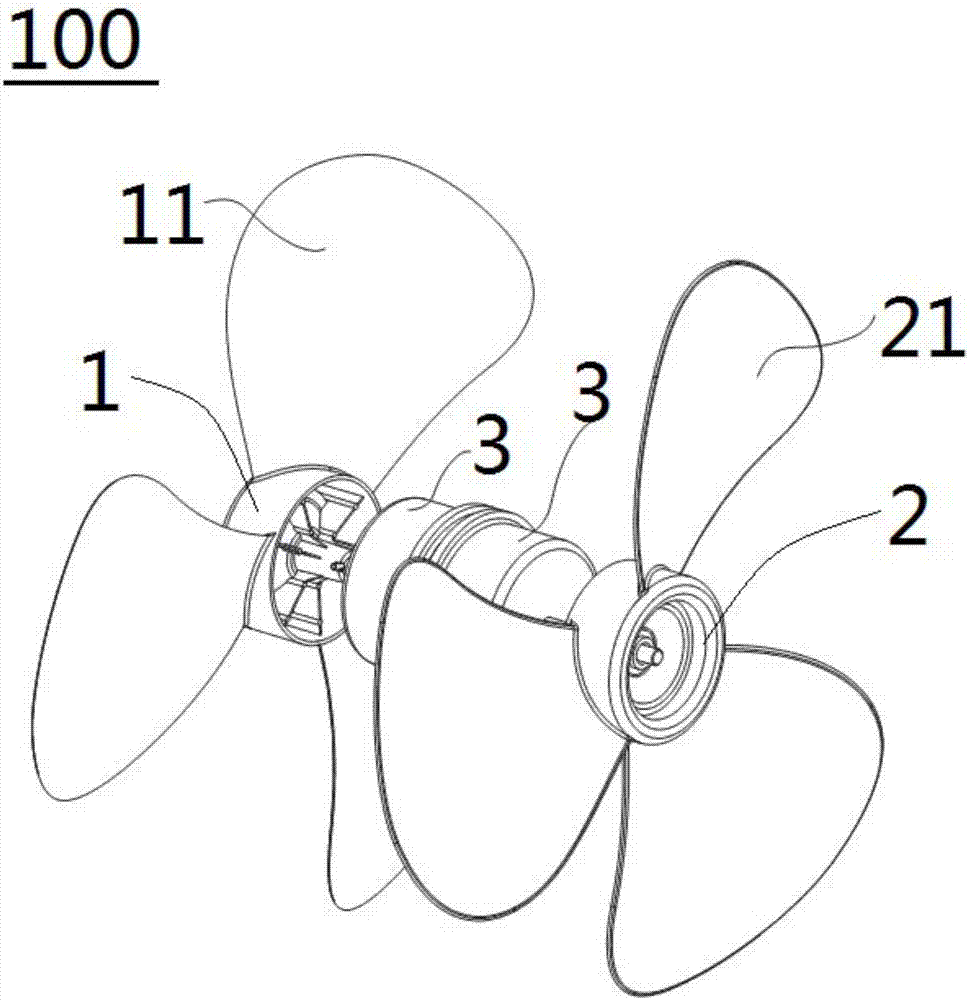

[0054] Such as figure 2 As shown, the structure of this embodiment is substantially the same as that of Embodiment 1, wherein the same components use the same reference numerals, the only difference is that the two driving motors 3 are located at the first axial flow wind wheel 1 and the second axial flow wind wheel between round 2.

Embodiment 3

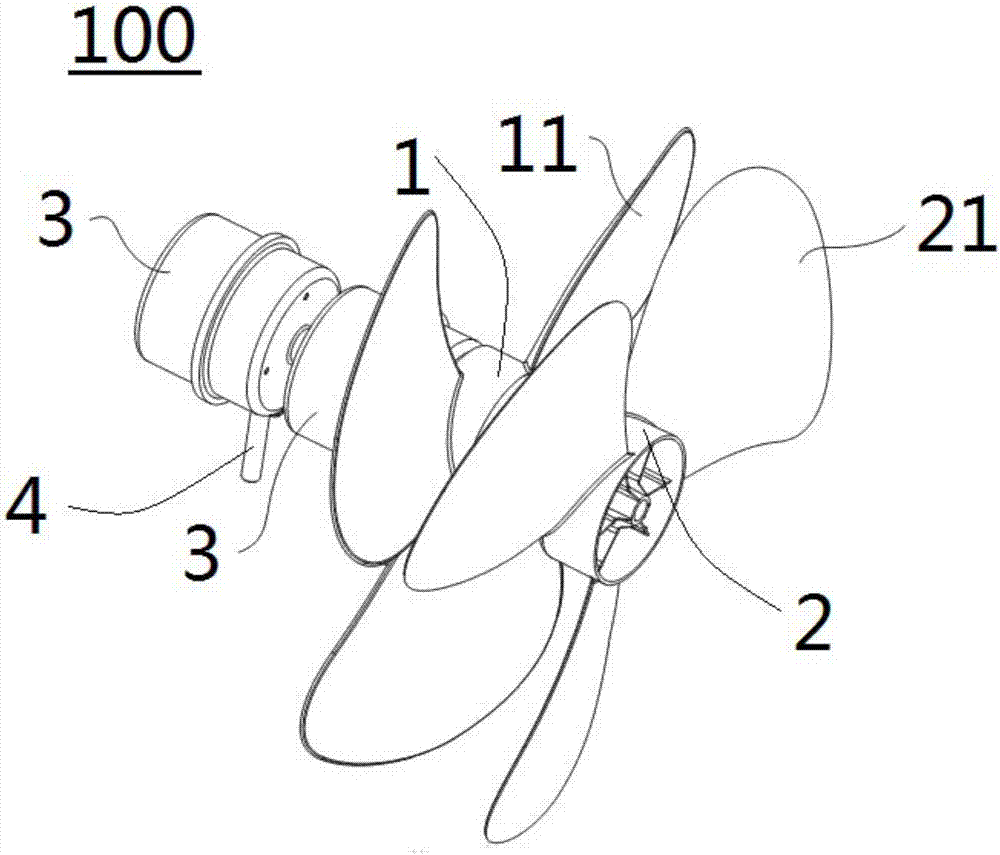

[0056] Such as image 3 As shown, the structure of this embodiment is substantially the same as that of Embodiment 1, wherein the same components use the same reference numerals, the only difference is that the two driving motors 3 are located at the side of the first axial flow wind wheel 1 far away from the second axis One side of the wind wheel 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com