Array substrate and manufacturing method thereof

A technology of an array substrate and a manufacturing method, which is applied in the field of liquid crystal displays, can solve the problems of low efficiency and complicated manufacturing process of the array substrate, and achieve the effects of reducing the yellow light manufacturing process, improving the production efficiency and saving the cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

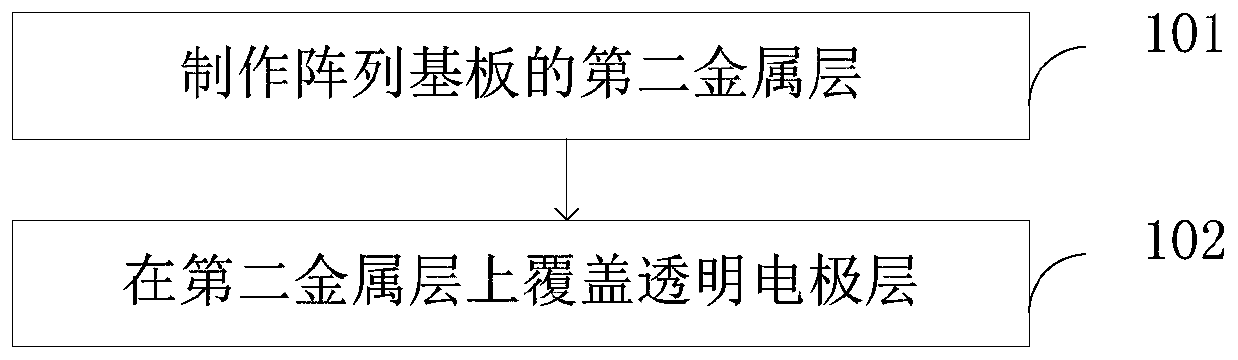

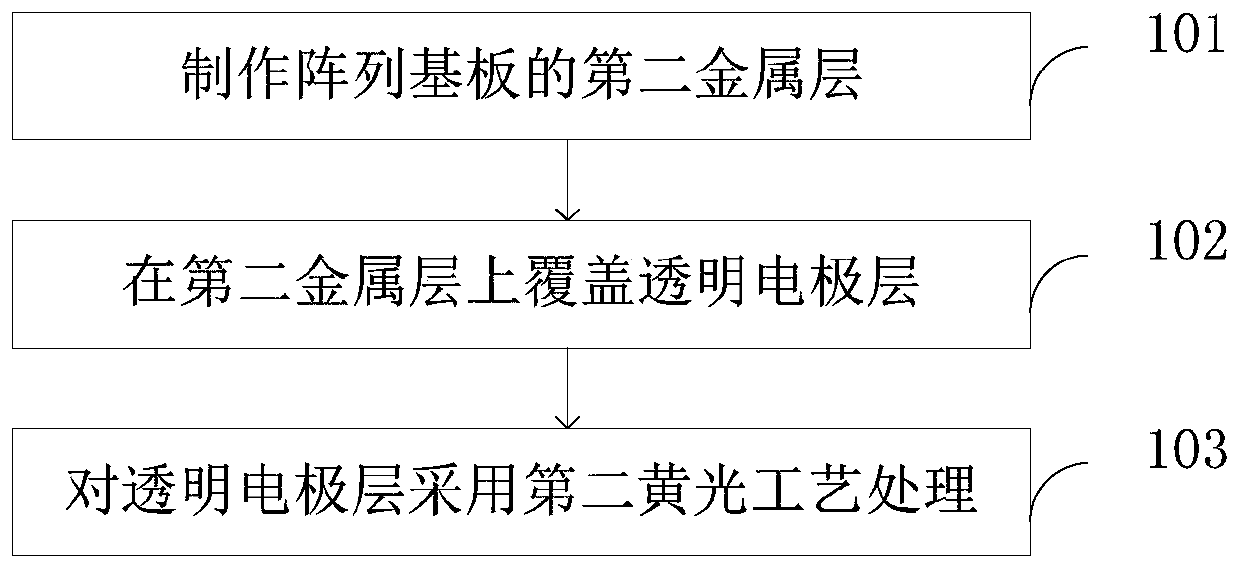

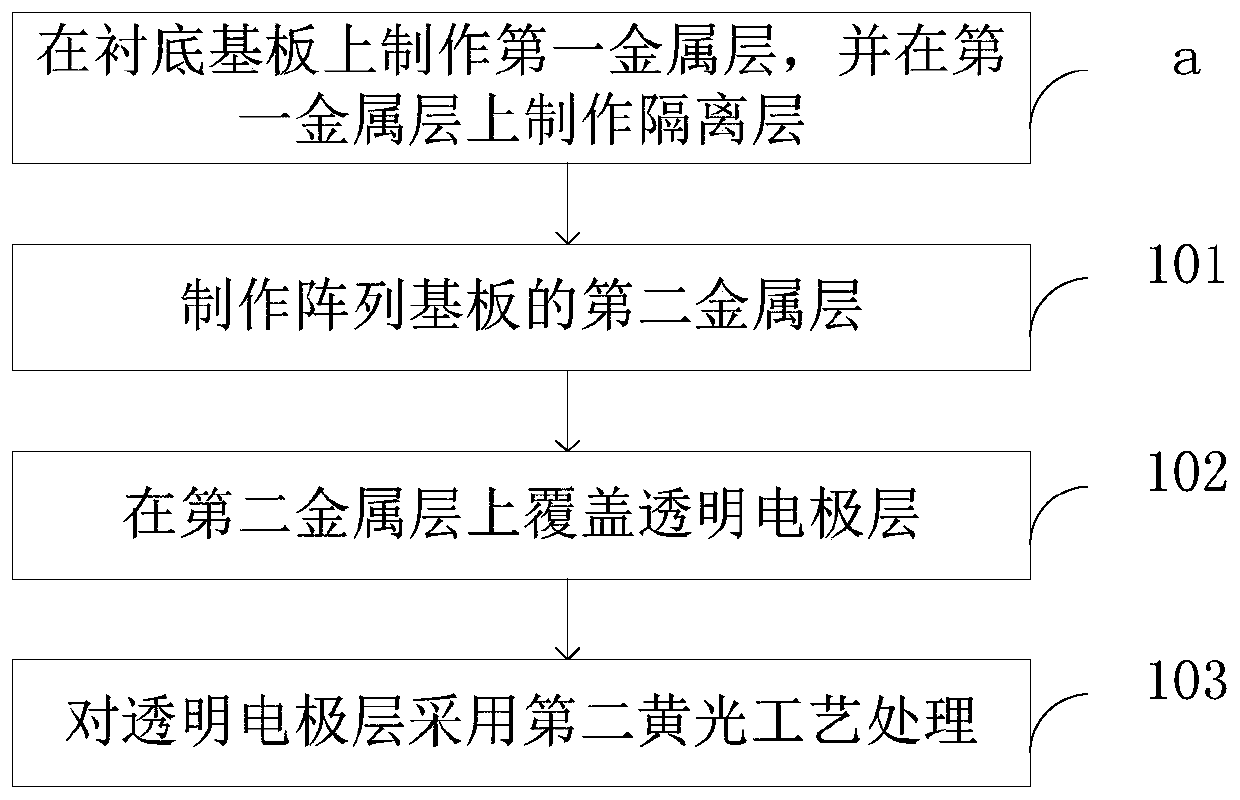

[0029] Such as figure 1 As shown, Embodiment 1 of the present invention provides a method for manufacturing an array substrate, including:

[0030] In step 101, a second metal layer of the array substrate is fabricated, and the second metal layer is formed by a metal thin film layer treated by a first yellow light process. In the semiconductor industry, silicon wafers or metal thin films are coated, soft-baked, exposed, developed, and hard-baked to make certain patterns. This process is called yellow light, which is one of the fine circuit manufacturing processes. Specifically, the yellow light process (including the first yellow light process and the second yellow light process hereinafter) is a process of processing the metal thin film layer to include at least one pattern, and the specific steps include coating a photoresist on the metal thin film layer, Then use the first mask to expose the photoresist, then use the developer to wash away the photoresist to be etched, and...

Embodiment 2

[0040] An embodiment of the present invention provides an array substrate, including: a second metal layer and a transparent electrode layer directly covering the second metal layer, wherein the second metal layer is formed by a metal thin film layer treated by a first yellow light process.

[0041] Further, the pattern of the second mask 2 used when the transparent electrode layer is subjected to the second yellow light process includes the pattern of the first mask 1 used when the metal thin film layer is subjected to the first yellow light process. Such as Figure 4 , Figure 5 as shown, Figure 4 is the pattern of the first mask plate 1, Figure 5 It is the pattern of the second mask plate 2, which includes the pattern of the first mask plate 1 (the pattern of the first mask plate 1 is composed of the unetched part of the second metal layer), so that When the transparent electrode layer is etched, the second metal layer will not be damaged.

[0042] Furthermore, in ano...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com