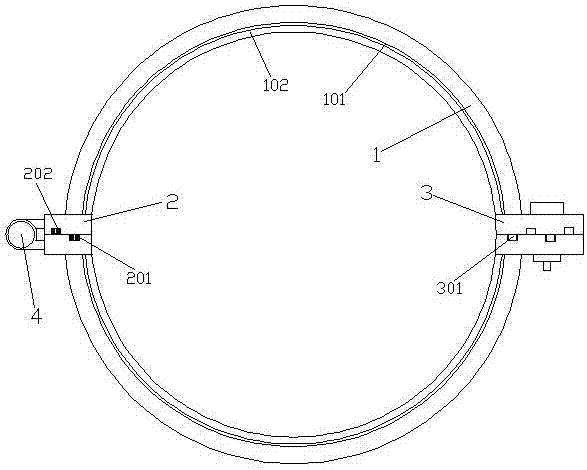

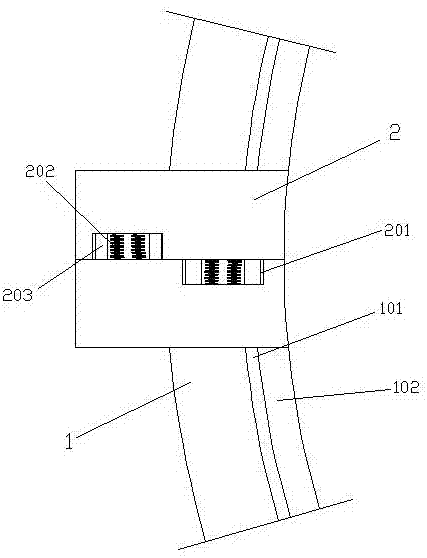

Assembling type external shell used for power generator

An outer shell, assembled technology, which is applied in the directions of electromechanical devices, casing/cover/support, application, etc., can solve the problem of inconvenient maintenance of the cylindrical generator casing, and achieve the convenience of chemical bonding or physical bonding, The effect of increased contact area and large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0060] The ceramic layer 102 is made by mixing ceramic powder with a fineness of no more than 200 meshes and metal aluminum wires with a diameter of no more than 1 mm and a length of no more than 3 mm at a weight ratio of 100:3, and then fired at 1600°C. Weight ratio, the ceramic powder consists of 40 parts of kaolin, 10 parts of silicon micropowder, 20 parts of quartz sand, 6 parts of kyanite fine powder with a fineness of no more than 100 microns, and 5 parts of active kyanite powder with a fineness of no more than 5 microns. Composed of alumina micropowder, 3 parts of silicon carbide micropowder and 4 parts of elemental silicon powder;

[0061] The firing method of the metal and ceramic high-temperature bonding layer 101 and the ceramic layer 102 includes the following steps:

[0062] 1) Weigh the metal aluminum wire and the raw materials that make up the ceramic powder according to the above ratio, and mix them, and add water equal to the total weight of the material, acet...

Embodiment 2

[0071] The ceramic layer 102 is made by mixing ceramic powder with a fineness of no more than 200 meshes and metal aluminum wires with a diameter of no more than 1mm and a length of no more than 3mm in a weight ratio of 100:5, and then fired at 1600°C. Weight ratio, the ceramic powder consists of 45 parts of kaolin, 15 parts of silicon micropowder, 24 parts of quartz sand, 8 parts of kyanite fine powder with a fineness of no more than 100 microns, and 7 parts of active kyanite with a fineness of no more than 5 microns. Composed of alumina micropowder, 5 parts of silicon carbide micropowder and 6 parts of elemental silicon powder;

[0072] The firing method of the metal and ceramic high-temperature bonding layer 101 and the ceramic layer 102 includes the following steps:

[0073] 1) Weigh the metal aluminum wire and the raw materials that make up the ceramic powder according to the above ratio, and mix them, and add water equal to the total weight of the material, acetone of 3%...

Embodiment 3

[0082] The ceramic layer 102 is made by mixing ceramic powder with a fineness of no more than 200 meshes and metal aluminum wires with a diameter of no more than 1mm and a length of no more than 3mm at a weight ratio of 100:4, and then fired at 1600°C. Weight ratio, the ceramic powder consists of 42.5 parts of kaolin, 12.5 parts of silicon micropowder, 22 parts of quartz sand, 7 parts of kyanite fine powder with a fineness of no more than 100 microns, and 6 parts of active kyanite with a fineness of no more than 5 microns. Composed of alumina micropowder, 4 parts of silicon carbide micropowder and 5 parts of elemental silicon powder;

[0083] The firing method of the metal and ceramic high-temperature bonding layer 101 and the ceramic layer 102 includes the following steps:

[0084] 1) Weigh the group of metal aluminum wire and the raw materials that make up the ceramic powder according to the above ratio, and mix them, and add water equal to the total weight of the material, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Fineness | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com