Flexible circuit board and manufacturing method thereof

A flexible circuit board and manufacturing method technology, applied in the directions of printed circuits, printed circuits, printed circuit components, etc., can solve the problems of high material cost, large signal attenuation of transmission lines, large dielectric loss, etc., to reduce signal transmission loss, reduce The effect of production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0036] The flexible circuit board and the manufacturing method of the flexible circuit board provided by the present invention will be described in detail below in conjunction with specific embodiments.

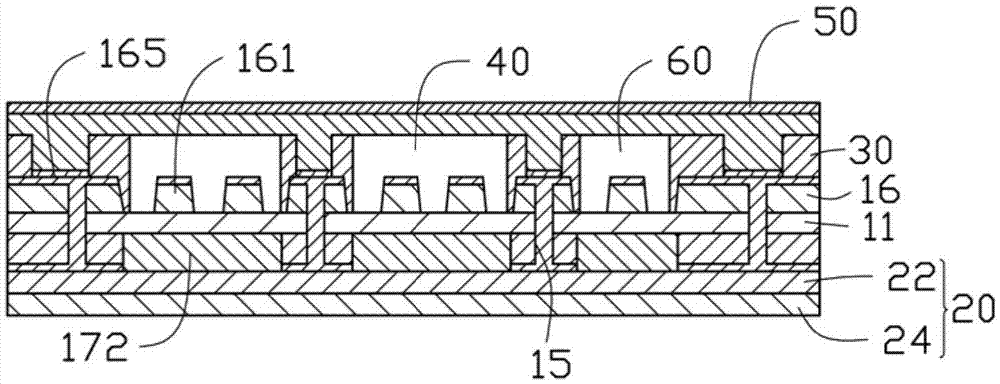

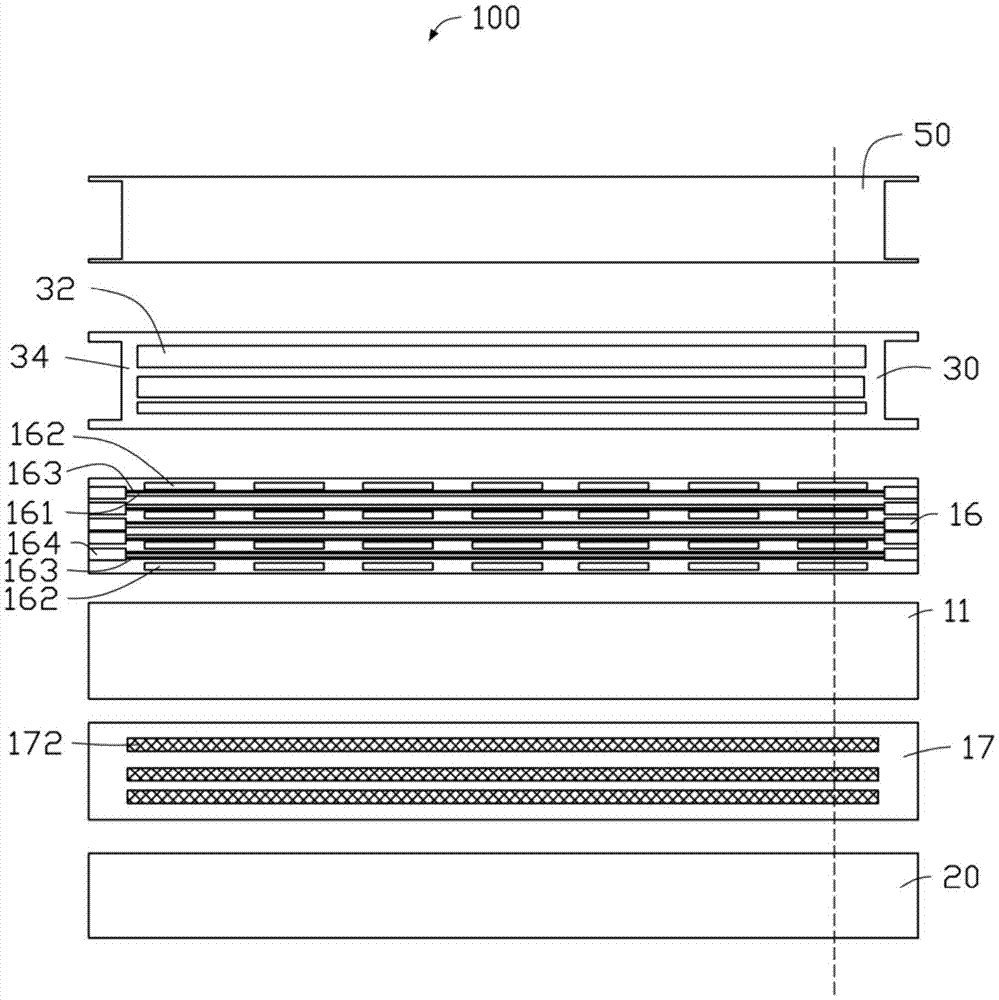

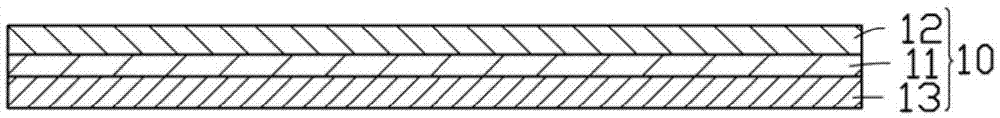

[0037] see figure 1 and figure 2 , a flexible circuit board 100 provided by the present invention, the flexible circuit board 100 includes a base layer 11, a first conductive circuit layer 16 and a second conductive circuit layer 17 formed on opposite sides of the base layer 11, formed The protective layer 20 on the second conductive circuit layer 17 , the photosensitive film 30 formed on the first conductive circuit layer 16 , and the anti-electromagnetic interference layer 50 formed on the photosensitive film 30 .

[0038] The first conductive circuit layer 16 includes at least one linear signal line 161 , at least two ground lines 162 and at least two hollow areas 163 . In this embodiment, the first conductive circuit layer 16 includes five linear signal lines 161 , fou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com